Novel three-tower RTO equipment

A new type of equipment technology, applied in the field of new three-tower RTO equipment, can solve the problems of increasing the secondary pollution of RTO processing equipment, reducing the sealing performance of the valve control period, reducing the gas reaction processing efficiency, etc., so as to facilitate maintenance, switching and processing The efficiency is stable and stable, and the effect of improving the anti-leakage effect

Pending Publication Date: 2022-06-21

澳斯意环保工程(苏州)有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The principle of RTO waste gas treatment equipment is to heat the organic waste gas to above 760 degrees Celsius, so that the VOC in the waste gas is oxidized and decomposed into carbon dioxide and water, and the high-temperature gas generated by oxidation flows through the The special ceramic regenerator makes the ceramic body heat up and "reserve heat". This "heat storage" is used to preheat the organic waste gas that enters later. In the current 2-box RTO system in the industry, the waste gas treatment efficiency often cannot exceed 95%. , it is not competitive in response to some higher environmental protection requirements, so many companies often can only choose the three-chamber RTO system process device with higher theoretical processing efficiency;

The current RTO exhaust gas treatment equipment generally needs to control the gas to flow uniformly to the RTO treatment chamber of the second or third tower through valves during the period when the gas is fed into the combustion chamber, but the more the number of valves, the more difficult the control will be. And when the valve controls the switching of the gas, the gas is prone to leak during the switching operation, which reduces the sealing performance of the valve during the control period. When the gas is subjected to RTO treatment, the exhaust gas in the treatment system may not fully react. Directly discharged into the atmosphere, reducing the reaction treatment efficiency of the gas and increasing the secondary pollution of the gas RTO treatment equipment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

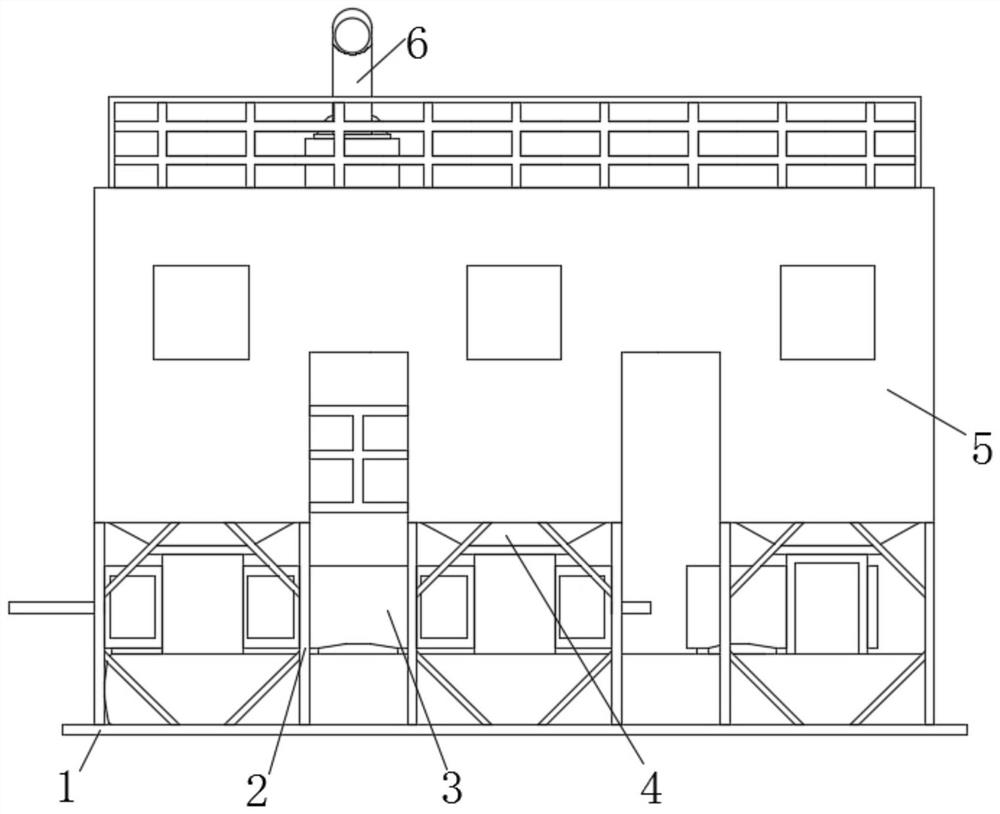

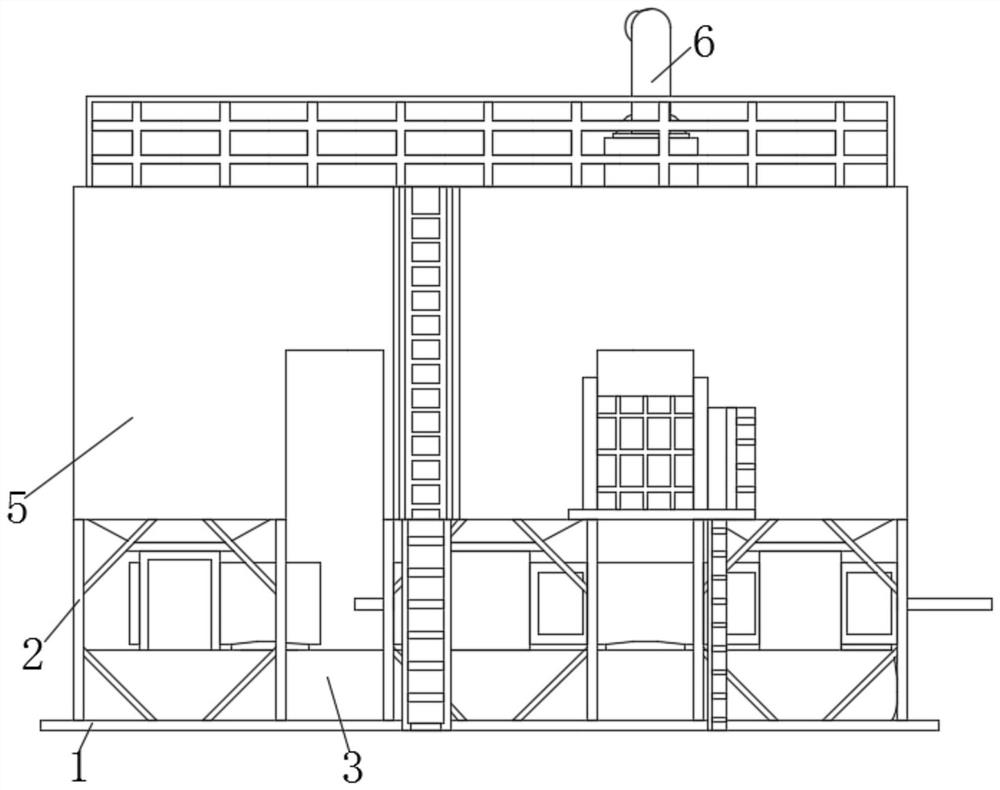

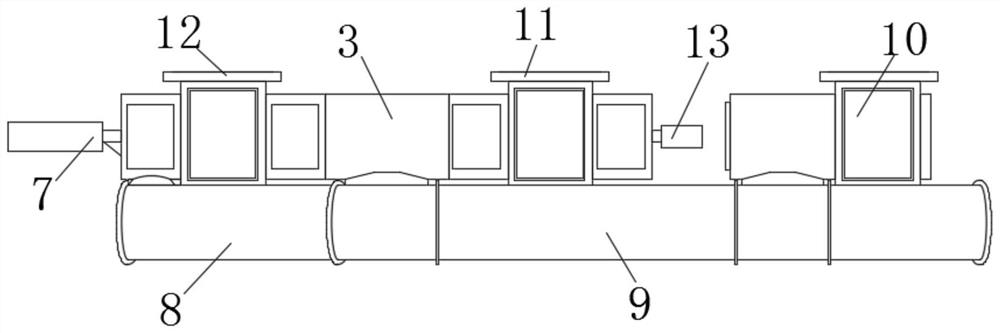

The novel three-tower RTO equipment comprises a base and a combustor module, three sets of ceramic supporting seats are arranged at the top of the base in rows, switching valves are arranged on the inner sides of the three sets of ceramic supporting seats, a combustion chamber is arranged at the tops of the three sets of ceramic supporting seats, and three sets of communicating openings are formed in the bottom of the combustion chamber in rows; one side of the top of the combustion chamber is provided with an emergency emptying valve which is communicated with the combustion chamber, one side of the switching valve is provided with a first electric push rod, and the other side of the switching valve is provided with a second electric push rod; a first electric push rod and a second electric push rod are matched with each other to serve as an actuator to control the communication relation of a second gas guide port, a third gas guide port and a switching valve, and gas can be evenly guided into a combustion chamber under movable sealing of a second sealing piston and a first sealing piston; and the circulation performance and the anti-leakage effect of the gas in the combustion chamber are improved.

Description

technical field [0001] The invention relates to the technical field of RTO waste gas treatment, in particular to novel three-tower RTO equipment. Background technique [0002] The principle of RTO waste gas treatment equipment is to heat the organic waste gas to above 760 degrees Celsius, so that the VOC in the waste gas is oxidized and decomposed into carbon dioxide and water. ", this "heat storage" is used to preheat the organic waste gas that enters later. In the current 2-box RTO system in the industry, the waste gas treatment efficiency often cannot exceed 95%, and it is not competitive in meeting some higher environmental protection requirements. Therefore, Many enterprises often can only choose the three-chamber RTO system process device with higher theoretical processing efficiency; The current RTO exhaust gas treatment equipment generally needs to control the gas to flow uniformly to the RTO treatment chamber of the second or third tower through valves during the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F23G7/06F23G5/46F23G5/50

CPCF23G7/06F23G5/46F23G5/50

Inventor 张显磊周文祥

Owner 澳斯意环保工程(苏州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com