Internal mixer for producing V-belt and operation method of internal mixer

An internal mixer and internal mixing technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve problems such as insufficient mixing of rubber raw materials and powder materials, shortened service life, and easy environmental pollution, and achieve convenient Secondary filtration, obvious beneficial effect, and the effect of reducing exhaust gas pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

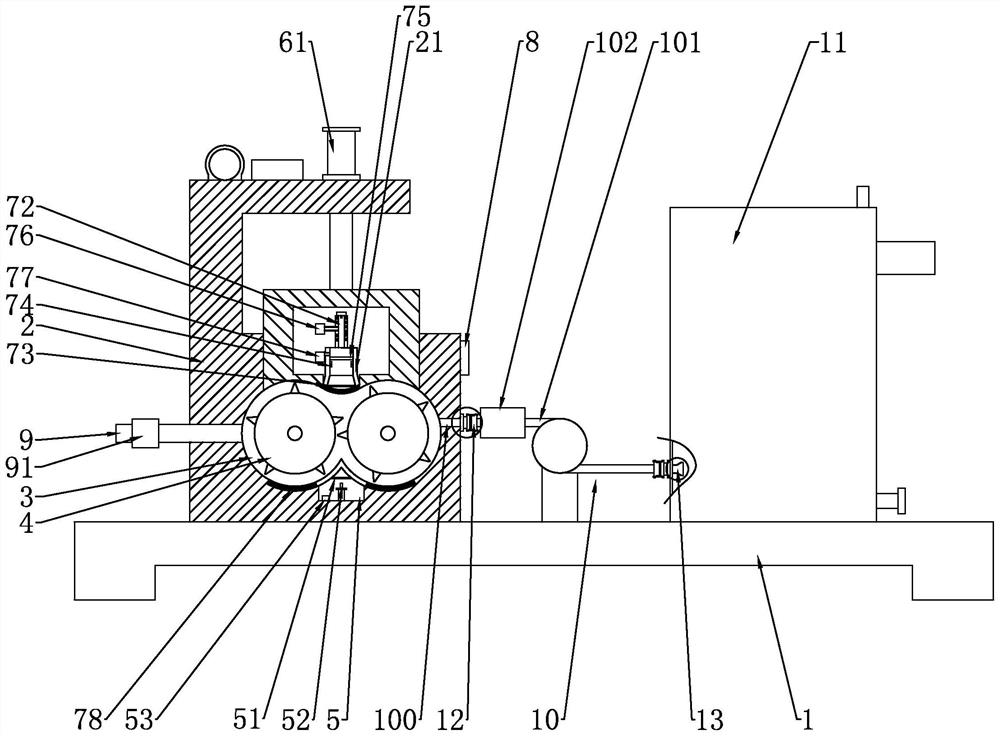

[0071] like Figure 1 to Figure 6 As shown, the embodiment of the present application provides an internal mixer for producing a V-belt, comprising a base 1 on which an internal mixer body 2 is arranged, and further comprising:

[0072] Mixing chamber 3, a rotor 4 driven by a motor is arranged in the mixing chamber 3, and a cooling chamber 5 is arranged below the mixing chamber 3;

[0073] The pressure block 6 is provided with an electron beam emission system 7 in the pressure block 6;

[0074] The control box 8, the control box 8 is arranged on the base 1;

[0075] The intake pipe 9, a booster pump 91 is arranged on the intake pipe 9;

[0076] The smoke exhaust system 10 is used to discharge the waste gas in the mixing chamber 3;

[0077] Filter tower 11, filter tower 11 is used to filter waste gas;

[0078] Among them, the mixing chamber 3 is arranged inside the mixer body 2, the pressure block 6 is driven by the hydraulic system 61 to move up and down and cooperate with...

Embodiment 2

[0081] In this embodiment, in addition to including the structural features of the foregoing embodiments, the further electron beam emission system 7 also includes:

[0082] The ionization chamber 71, one end of the ionization chamber 71 is provided with a hollow cathode device 72, the other end is provided with a grid acceleration device 73 and a permeable plate, and the interior of the ionization chamber 71 is provided with a permanent magnet 74 and a neutralizer 75;

[0083] a first propellant device 76, the first propellant device 76 is connected to the hollow cathode device 72 through a pipeline;

[0084] The second pushing device 77, the second propellant device 77 communicates with the ionization chamber 71 through a pipeline;

[0085] Cathode arc plate 78, the cathode arc plate 78 is arranged at the bottom of the mixing chamber 3;

[0086] Among them, the hollow cathode device 76 is composed of a cylindrical tube, a resistance wire, a cathode discharger and a pressuri...

Embodiment 3

[0089] In this embodiment, in addition to including the structural features of the foregoing embodiments, the further smoke exhaust system 10 further includes:

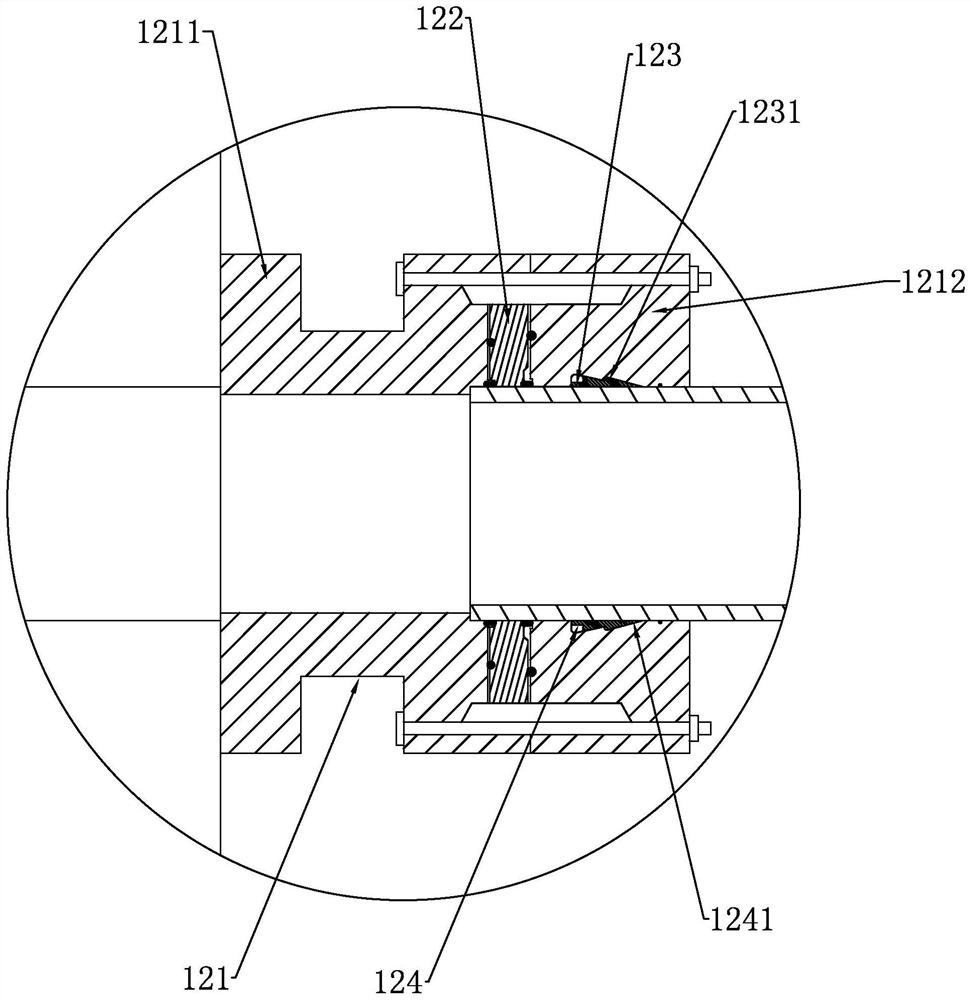

[0090] The flue gas port 100, the flue gas port 100 is respectively arranged on the mixing chamber 3 and the filter tower 11, and the flue gas port 100 is provided with a disassembly interface 12;

[0091] a smoke exhaust pipe 101, a fan 102 is arranged in series on the smoke exhaust pipe 101;

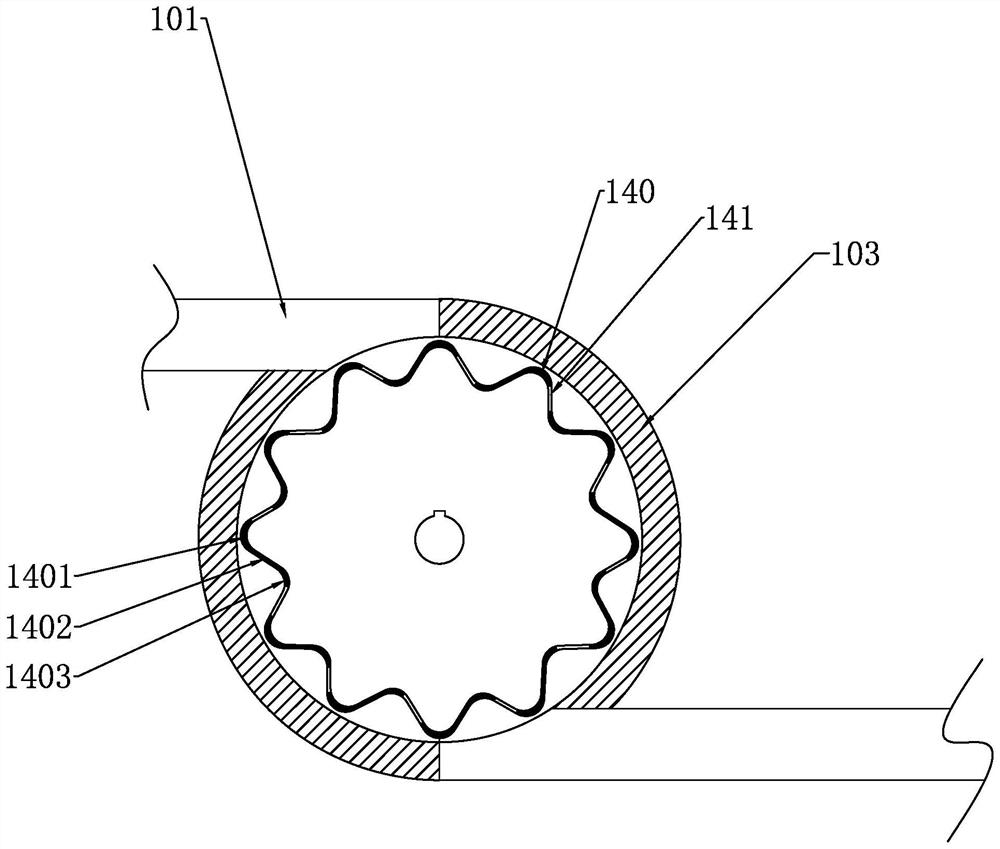

[0092] The primary filtration cavity 103, the primary filtration cavity 103 is arranged on the smoke exhaust pipe 101 in series;

[0093] The cigarette outlet 13, the cigarette outlet 13 is arranged at the smoke outlet end of the smoke exhaust pipe 101;

[0094] Wherein, the two ends of the exhaust pipe 101 are respectively connected to the flue gas port 100 at the mixing chamber 3 and the smoke port 100 at the filter tower 11 through the disassembly interface 12, and the exhaust gas in the mixing chamber 3 passes through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com