Coating liquid and preparation method and chemical strengthening method thereof

A coating solution and chemical technology, applied in coatings, alkali metal silicate coatings, etc., can solve environmental problems such as unfavorable environmental protection, achieve the effects of reducing the use of solvents, reducing the probability of bluing, and reducing the amount of release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

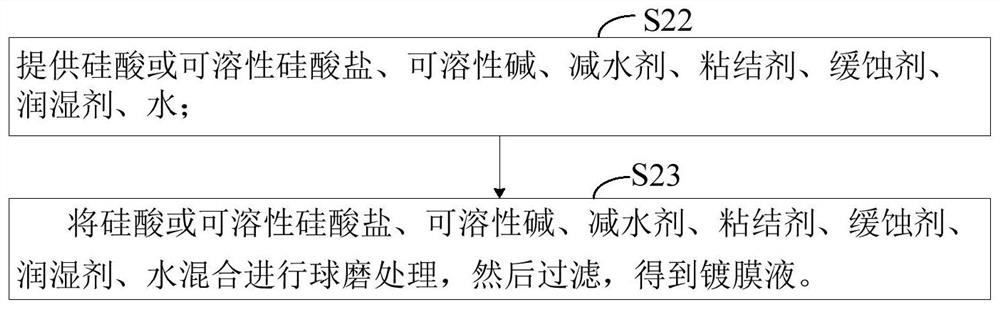

[0046] A second aspect of the embodiments of the present application provides a method for preparing a coating solution, such as figure 1 shown, including the following steps:

[0047] S11: Provide silicic acid or soluble silicate, soluble alkali, water reducing agent, binder, corrosion inhibitor, wetting agent, water;

[0048] S12: Mix silicic acid or soluble silicate, soluble alkali, water reducing agent, binder, corrosion inhibitor, wetting agent and water for ball milling treatment, and then filter to obtain a coating solution.

[0049] The preparation method of the coating solution provided in the embodiment of the present application comprises mixing silicic acid and / or a soluble silicate, a soluble alkali, a water reducing agent, a binder, a corrosion inhibitor, a wetting agent, and water, performing ball milling, and filtering, The coating solution can be obtained. The preparation process is simple, easy to operate and low in production cost.

[0050] In step S11 , ...

Embodiment 1A

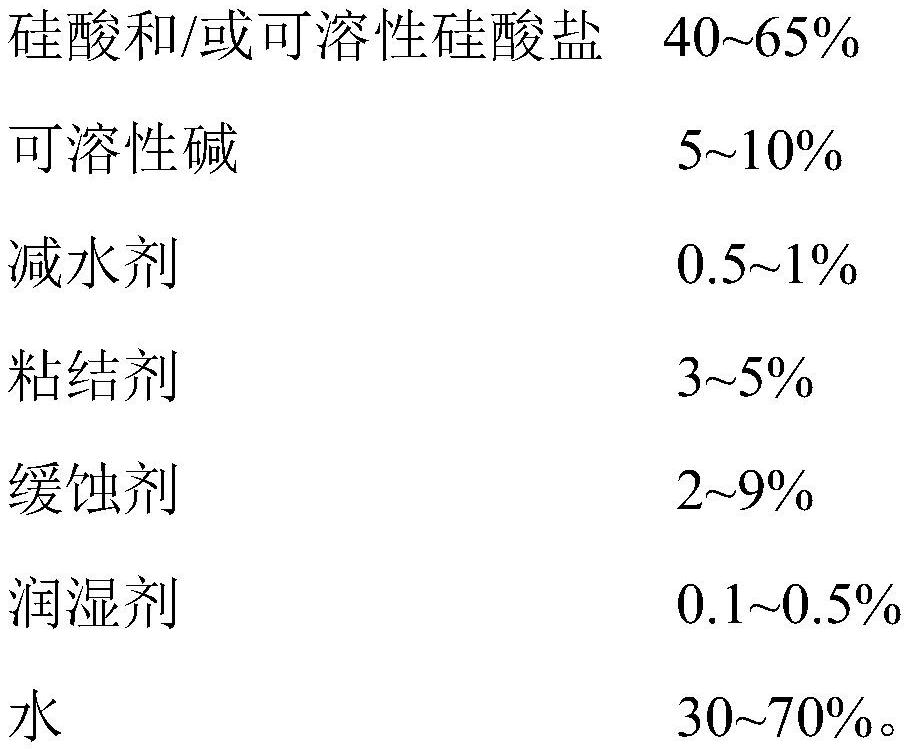

[0069] This embodiment provides a coating solution and a preparation method thereof.

[0070] A coating solution (100% by total weight), comprising the following components by weight:

[0071]

[0072] A preparation method of a coating solution, comprising the following steps:

[0073] S11: provide each raw material component according to the coating solution of this embodiment;

[0074] S21: mixing the raw material components for 20min ball milling, then passing through a 300-mesh sieve, standing for 30min, and then passing through a 300-mesh sieve to obtain a coating solution.

Embodiment 1B

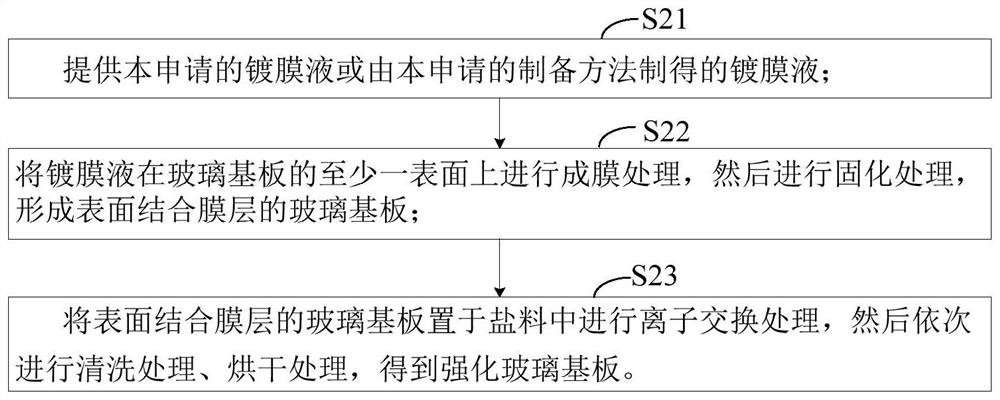

[0076] The present embodiment provides a chemical strengthening method, comprising the following steps:

[0077] S21: Provide the coating solution provided in Example 1A and a float high alumina silicate glass substrate with a thickness of 0.7 mm and a size of 10 inches;

[0078] S22: coating the coating liquid on the air surface of the glass substrate, and then heating and curing after drying to form a glass substrate with a surface-bonded film layer, and the thickness of the film layer is 3 μm;

[0079] S23: chemically strengthen the glass substrate by chemical strengthening process;

[0080] Preheating treatment: According to the heating rate of 6.3°C / min, the glass substrate with the surface bonded film layer is heated from room temperature (25±5°C) to 380°C, and then kept for 15min;

[0081] Ion exchange treatment: put the glass substrate in potassium nitrate at a temperature of 410°C for 5 hours, then lift the glass substrate to drop salt for 5 minutes; then cool the gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com