Method for producing liquid fuel from biomass

A liquid fuel and biomass technology, which is applied to liquid carbon-containing fuels, gas fuels, fuels, etc., can solve the problems of incomplete fermentation, complex biomass liquid fuel components, and low utilization efficiency of biomass raw materials, and improve the conversion rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

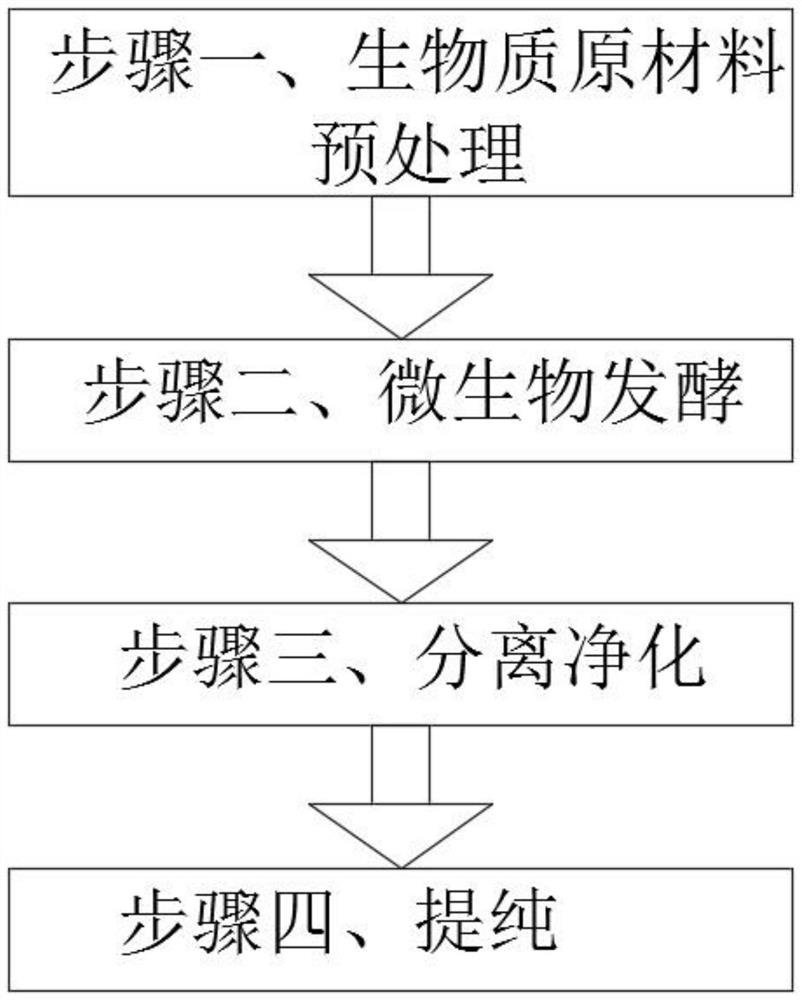

[0026] like figure 1 As shown, the present invention provides a method for utilizing biomass to produce liquid fuel, and the method for utilizing biomass to produce liquid fuel includes the following steps:

[0027] Step 1, pretreatment of biomass raw materials;

[0028] Step 2, microbial fermentation;

[0029] Step 3, separation and purification;

[0030] Step four, purification.

[0031] In this embodiment, the biomass raw materials are firstly pretreated to ensure that the subsequent processing process is not affected, and then the biomass raw materials are decomposed and transformed by microorganisms to convert them into usable liquid fuels, and then separated and purified. The by-products and impurities in the production process of liquid fuel are separated, and finally, the liquid fuel is separated from components with different carbon content through purification, so as to improve the utilization efficiency of liquid fuel.

Embodiment 2

[0033] like figure 1 As shown, on the basis of Example 1, the present invention provides a technical solution: preferably, the step 1 further includes, the biomass raw materials are sugar cane, corn and other sugar- or starch-containing food biomass or fast-growing It is composed of lignocellulosic biomass such as forest wood and discarded crop straw. The above biomass raw materials are concentrated and washed with high pressure to remove soil and ash on the biomass raw materials, and then the bulk solid impurities in the biomass raw materials are removed by flotation. , put the cleaned and flotated biomass raw materials into the crusher for crushing and mixing, crush them into suitable particles according to actual needs, and then dry the crushed biomass raw materials through a drying device to remove moisture. .

[0034] In this embodiment, the biomass raw materials are first cleaned and flotated to facilitate the removal of soil, ash and bulk solid impurities that cannot b...

Embodiment 3

[0036] like figure 1 As shown, on the basis of Example 1, the present invention provides a technical solution: preferably, the step 2 further includes: putting the pretreated biomass raw materials into the reactor, and putting the microorganisms into the reactor according to the proportion At the same time, keep the pressure in the reaction kettle at normal pressure and the temperature at 30 to 45 degrees Celsius. After standing for 6 hours, the reaction kettle is stirred by the stirring device, so that the biomass raw materials and the microbial starter are fully mixed and repeated. Two to three times of the above process, a large amount of gas will be generated during the fermentation of biomass raw materials. The gas contains combustible organic gas components and non-combustible gas components. The gas is continuously exported and collected through the pipeline to maintain the internal pressure balance of the reactor.

[0037] In this embodiment, during the fermentation pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com