Steelmaking multi-process multi-unit dynamic production method and production timetable making method

A multi-unit, multi-process technology, applied in the field of steelmaking production, can solve problems such as inaccurate matching of furnaces and machines, and incapable of dynamic monitoring of process furnace information, so as to achieve visual management, meet the high-speed production rhythm, and ensure the effect of ladle logistics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] The first embodiment provides a method for formulating a dynamic production schedule for steelmaking with multiple processes and multiple units. According to information such as steel grades, the standard cycle of each process is set, and the time of each stage is calculated from the opening of the converter to the end of casting, and the production schedule is formulated. , so that each process can be executed strictly according to the production time node, instead of manual calculation and offline communication, improve the matching accuracy of furnace machines, reduce labor intensity, ensure the stable connection of upstream and downstream processes, and improve production efficiency.

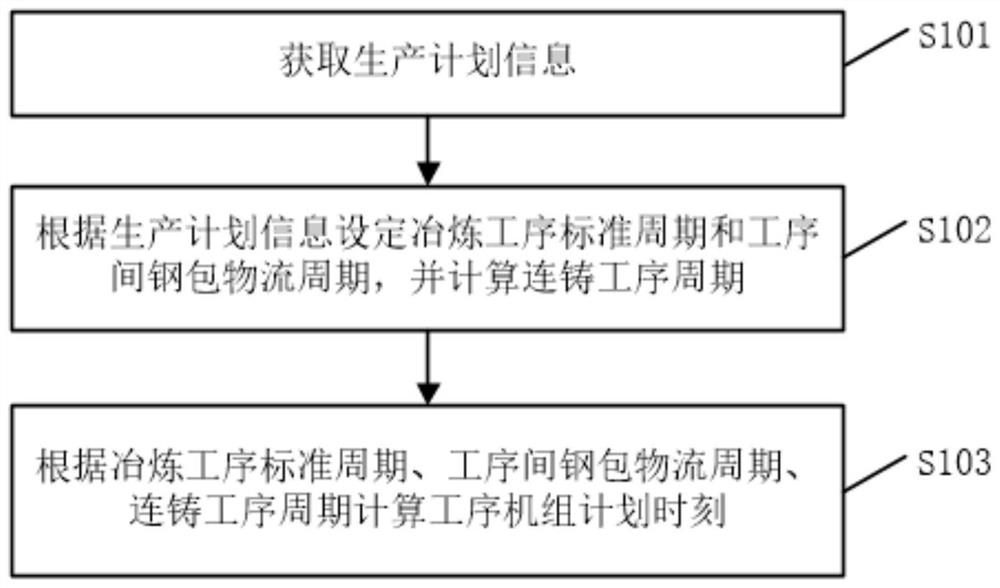

[0077] like figure 1 As shown, a method for formulating a dynamic production schedule for steelmaking with multiple processes and multiple units provided in this embodiment includes the following steps.

[0078] S101, obtain production planning information.

[0079] Obtain production...

Embodiment 2

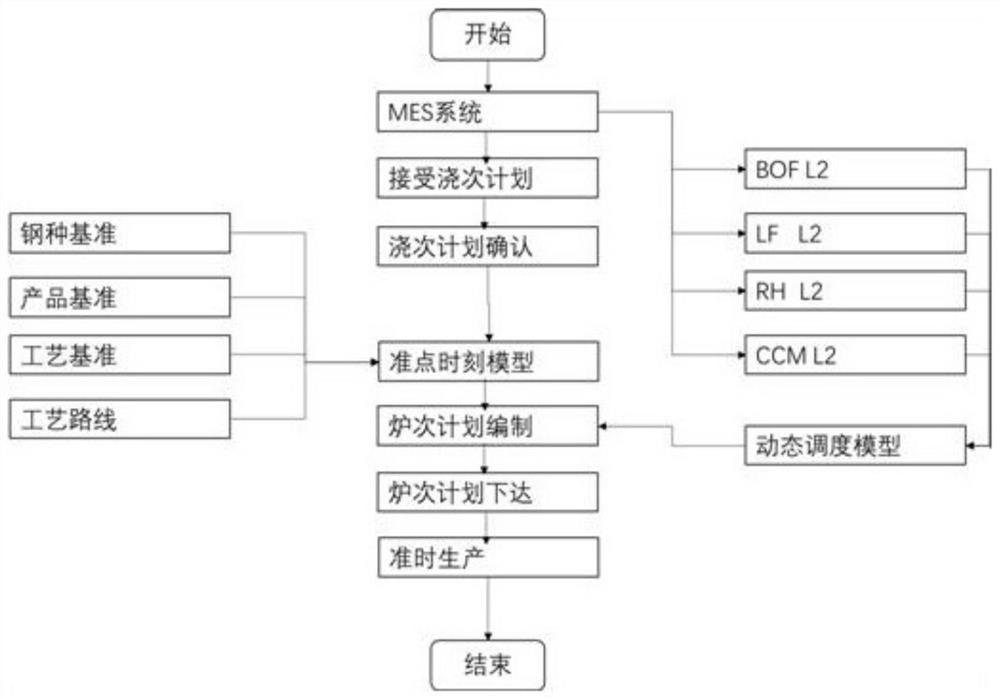

[0135] Based on the timetable formulation method of the first embodiment, the second embodiment provides a multi-process multi-unit dynamic production method for steelmaking, such as image 3 Shown is a schematic diagram of the principle of the method, including the following steps.

[0136] Step 1, obtain production planning information and pouring schedule from MES system;

[0137] Step 2, after confirming that the pouring schedule is correct, formulate a timetable based on the method of Embodiment 1, and prepare a furnace schedule;

[0138] The second step is to issue the furnace schedule.

[0139] Send the heat plan to the steelmaking automation system to control the on-time production of the furnace.

[0140] The method can be realized by the system, and realizes the maintenance of basic information, including the maintenance of production plan information, the set standard cycle of smelting process and the ladle logistics cycle between processes, and the operation stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com