Supported palladium-based catalyst for synthesizing dimethyl carbonate as well as preparation method and application of supported palladium-based catalyst

A technology of dimethyl carbonate and supported palladium, applied in the field of catalysis, can solve problems such as equipment corrosion and increase cost investment, and achieve the effects of non-corrosiveness, low loading and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

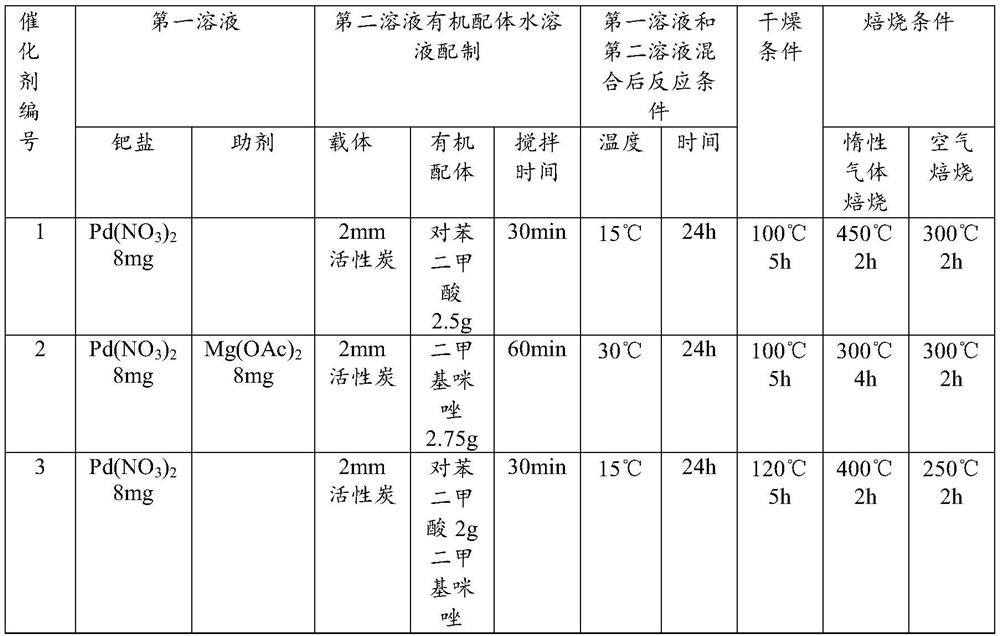

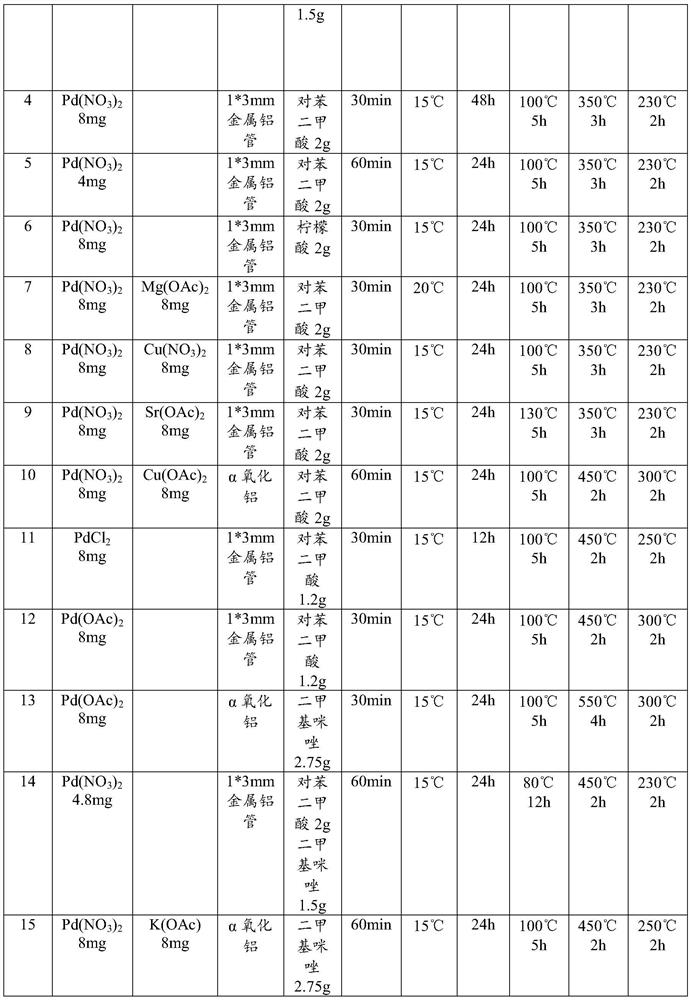

[0040] Example 1 - Preparation of catalyst

[0041] Weigh a certain amount of palladium salt (and auxiliary agent) and add it to 1mL of water or solvent to prepare the first solution, take a certain amount of organic ligand and add it to 10ml of water to prepare an organic ligand aqueous solution, and the organic ligand aqueous solution is continuously Stir for more than 30min, add a certain amount of carrier into the organic ligand aqueous solution to form a second solution, and keep stirring. The first solution is slowly added to the second solution under constant stirring, and thereafter, the reaction is stirred for a certain period of time. After the reaction, the solid-liquid was separated by filtration, the solid was dried in an oven, calcined in an inert gas atmosphere at a certain temperature for 1-4 hours, and then calcined in air for 1-3 hours to obtain a supported palladium-based catalyst sample.

[0042] The relationship between the sample number and the specific ...

Embodiment 2

[0047] Catalytic Performance Evaluation of Catalysts for Preparation of DMC

[0048] Take 1.2ml of the palladium-based catalyst prepared by the above different methods and put it in the constant temperature zone of the fixed-bed reactor (the upper and lower parts are filled with ceramic rings), and evaluate the catalytic activity, product selectivity and stability of the catalyst. The tube length of the fixed-bed reaction 30cm, inner diameter 6mm. After the catalyst is loaded, it is heated with nitrogen at a heating rate of 2°C / min. After reaching the target temperature, the nitrogen is switched to the prepared mixture of CO and methyl nitrite diluted with nitrogen. At the given temperature, pressure and The reaction was carried out at space velocity, and the outlet of the reactor was connected to Agilent gas chromatography for real-time quantitative analysis of product concentration. Agilent gas chromatography was equipped with two detectors, FID and TCD, and the chromatograp...

Embodiment 3

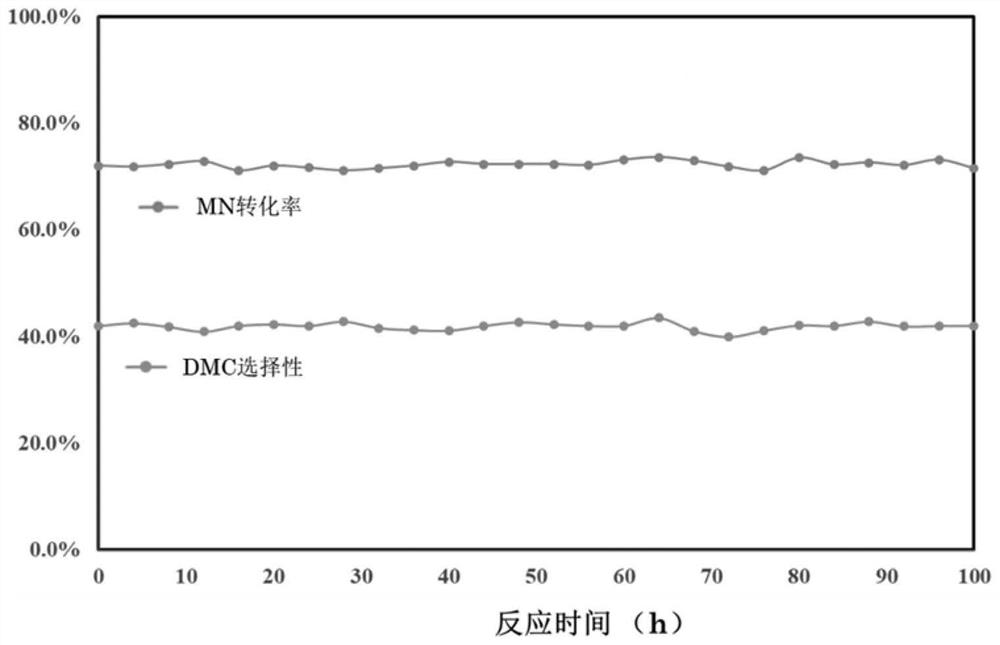

[0052] Example 3 Catalyst Stability Evaluation

[0053] Since the performance of each catalyst is similar, the present invention only takes No. 7 catalyst as an example to evaluate the stability of the catalyst. Measure 1.2 ml of No. 7 catalyst and put it in the constant temperature zone of the fixed-bed reactor (the upper and lower parts are filled with ceramic rings). The fixed-bed reaction tube has a length of 30 cm and an inner diameter of 6 mm. After the catalyst is loaded, it is heated to 175 °C with nitrogen gas at a heating rate of 2 °C / min. After reaching the target temperature, the nitrogen gas is switched to the prepared mixture of CO and methyl nitrite diluted with nitrogen, where the CO concentration is 9.6 %, MN concentration is 12%, airspeed 7000h -1 , the pressure is 0.1MPa (gauge pressure), the product is analyzed by Agilent gas chromatography, Agilent gas chromatography is equipped with two detectors, FID and TCD, and the chromatographic column has a polar c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube chief | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com