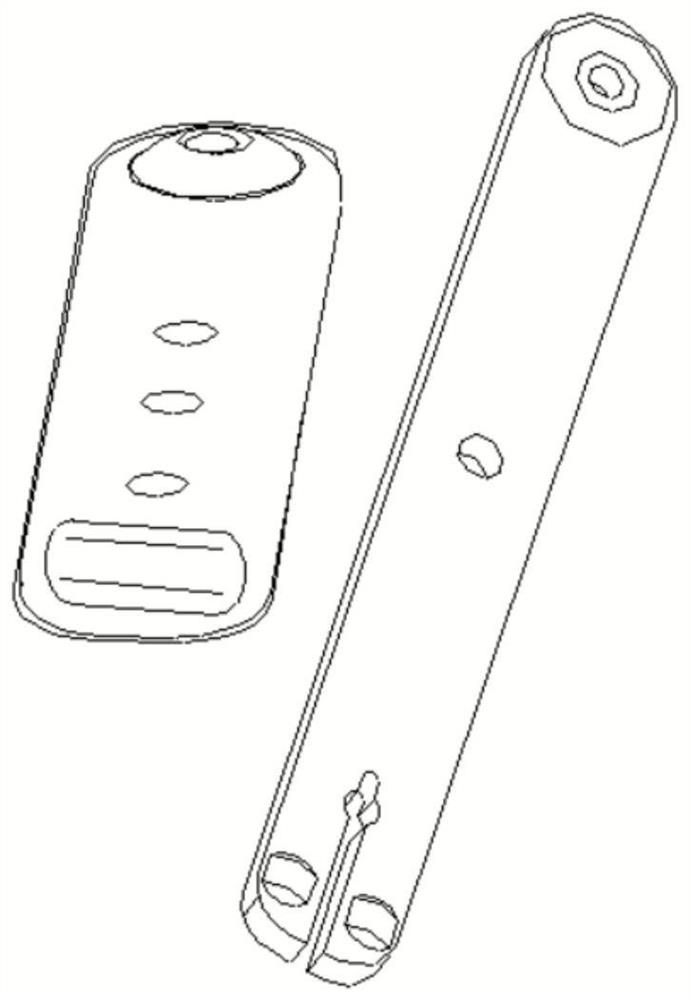

Preparation method of high-strength and high-conductivity copper alloy load switch knife

A load switch, copper alloy technology, applied in electrical switches, electrical components, circuits, etc., can solve the problems of low production efficiency and high cost, and achieve the effect of stable product performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A preparation method of a high-strength and high-conductivity copper alloy load switch knife, comprising the following steps:

[0052] S1. Raw material ratio:

[0053] By mass percentage, the raw materials include: Cr 0.05wt%, rare earth La 0.02wt%, and the balance is Cu; Cu includes three forms: sheet copper plate, long copper plate, copper skin;

[0054] S2. Electromagnetic stirring vacuum melting:

[0055] The feeding sequence is as follows: the sheet copper plate is placed at the bottom, the upper layer is added with long copper plates and placed evenly, the Cr block is wrapped with copper skin and placed in the middle of the copper plate, the rare earth La is wrapped with copper skin and added 5 minutes before being released;

[0056] A vacuum induction furnace is used for smelting and electromagnetic stirring for smelting, and the smelting temperature is controlled at 1150 ° C to obtain a uniform alloy solution; during the smelting process, argon gas is filled fo...

Embodiment 2

[0077] A preparation method of a high-strength and high-conductivity copper alloy load switch knife, comprising the following steps:

[0078] S1. Raw material ratio:

[0079] By mass percentage, the raw materials include: Cr 0.058wt%, rare earth La 0.03wt%, and the balance is Cu; Cu includes three forms: sheet copper plate, long copper plate, copper skin;

[0080] S2. Electromagnetic stirring vacuum melting:

[0081] The feeding sequence is as follows: the sheet copper plate is placed at the bottom, the upper layer is added with long copper plates and placed evenly, the Cr block is wrapped with copper skin and placed in the middle of the copper plate, the rare earth La is wrapped with copper skin and added 5 minutes before being released;

[0082] A vacuum induction furnace is used for smelting and electromagnetic stirring is used for smelting, and the smelting temperature is controlled at 1200 ° C to obtain a uniform alloy solution; during the smelting process, argon gas is ...

Embodiment 3

[0104] A preparation method of a high-strength and high-conductivity copper alloy load switch knife, comprising the following steps:

[0105] S1. Raw material ratio:

[0106] By mass percentage, the raw materials include: Cr 0.2wt%, rare earth La 0.05wt%, and the balance is Cu; Cu includes three forms: sheet copper plate, long copper plate, copper skin;

[0107] S2. Electromagnetic stirring vacuum melting:

[0108] The feeding sequence is as follows: the sheet copper plate is placed at the bottom, the upper layer is added with long copper plates and placed evenly, the Cr block is wrapped with copper skin and placed in the middle of the copper plate, the rare earth La is wrapped with copper skin and added 5 minutes before being released;

[0109] A vacuum induction furnace is used for melting and electromagnetic stirring is used for melting, and the melting temperature is controlled at 1400 ° C to obtain a uniform alloy solution; during the melting process, argon gas is charge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Softening temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com