Hyperbranched polymer delustering agent as well as preparation method and application thereof

A technology of hyperbranched polymers and matting agents, which is applied in the direction of coating, etc., can solve the problem of single functionalization, achieve the effect of avoiding agglomeration and improving the matting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The preparation method of the hyperbranched polyester with carboxyl at the end is:

[0055] Trimellitic anhydride and ethylene glycol were added to the three-necked flask, stirred and heated to 120 °C for 3 h, and then the solvent was distilled off under reduced pressure to obtain a pale yellow solid C. 11 H 10 O 7 In the three-necked flask, add trimellitic anhydride, C 11 H 10 O 7 , stirred and heated to 120 °C for 3 h, and then the solvent was distilled off under reduced pressure to obtain a hyperbranched polyester with a carboxyl group at the end.

Embodiment 1

[0057] The present embodiment provides a flame-retardant matting agent, and the preparation steps include:

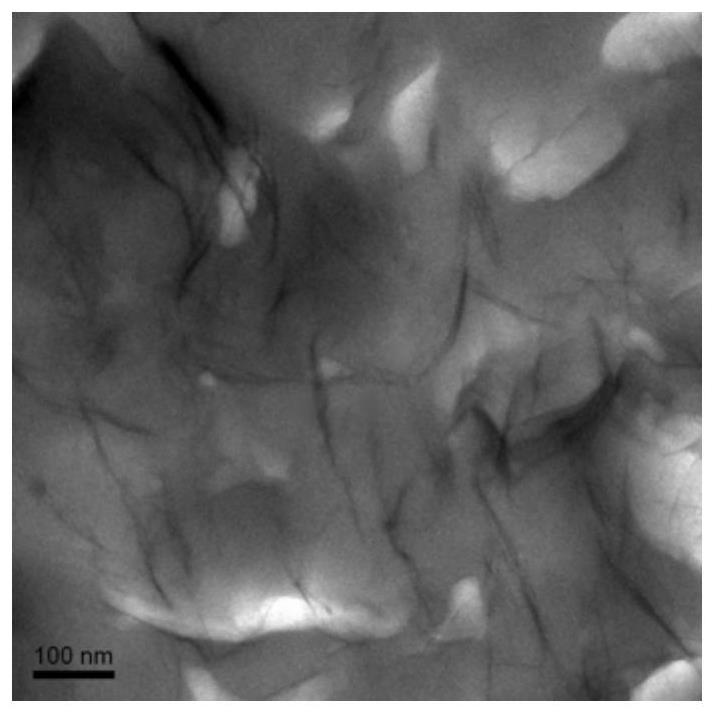

[0058] S1. 1 g of sodium-based montmorillonite was mechanically stirred at high speed in 2000 g of water for 2 h, and ultrasonically treated for 0.5 h to obtain a sodium-based montmorillonite lamellar dispersion with a wafer thickness of 0.9-5 μm in the aqueous dispersion.

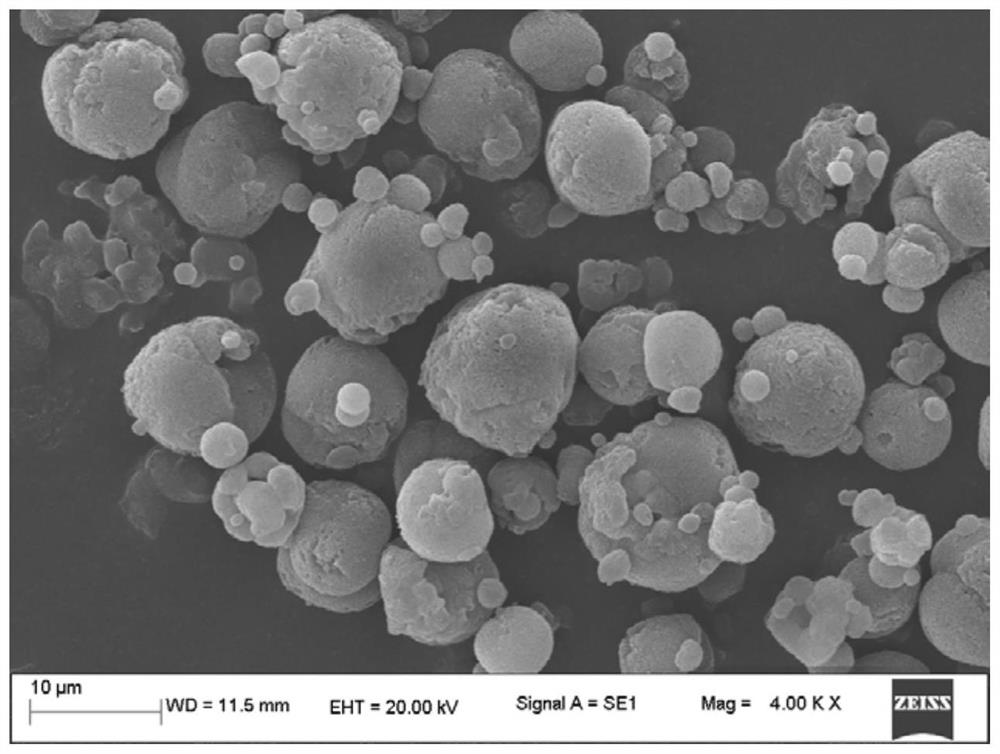

[0059] S2. Add 1 g of hexa-p-carboxyphenoxy cyclotriphosphazene (HCPCP) to the micron-level montmorillonite sheet dispersion in step S1, stir and mix at a high speed, heat up to 80-100 ° C, and react for 2 hours to make peeling off The hydroxyl groups on the montmorillonite sheets are completely esterified with the carboxyl groups of the hyperbranched polymer and form hydrogen bonds. The finished product is placed in a drying oven and dried at 60 °C for 12 hours to construct a montmorillonite composite hyperbranched polymer. material microspheres, that is, a matting agent with flame retardancy.

Embodiment 2

[0061] The present embodiment provides a matting agent with flame retardancy and antibacterial properties, and the preparation steps include:

[0062] S1. 1 g of sodium-based montmorillonite was mechanically stirred at high speed in 2000 g of water for 2 h, and ultrasonically treated for 0.5 h to obtain a sodium-based montmorillonite lamellar dispersion with a wafer thickness of 0.9-5 μm in the aqueous dispersion.

[0063] S2. Add 1 g of hexa-p-carboxyphenoxy cyclotriphosphazene (HCPCP) to the micron-level montmorillonite sheet dispersion in step S1, stir and mix at a high speed, heat up to 80-100 ° C, and react for 2 hours to make peeling off The hydroxyl group on the montmorillonite sheet layer completely undergoes esterification reaction with the carboxyl group of the hyperbranched polymer and forms a hydrogen bond to construct a montmorillonite composite hyperbranched polymer microsphere, that is, a matting agent with flame retardancy.

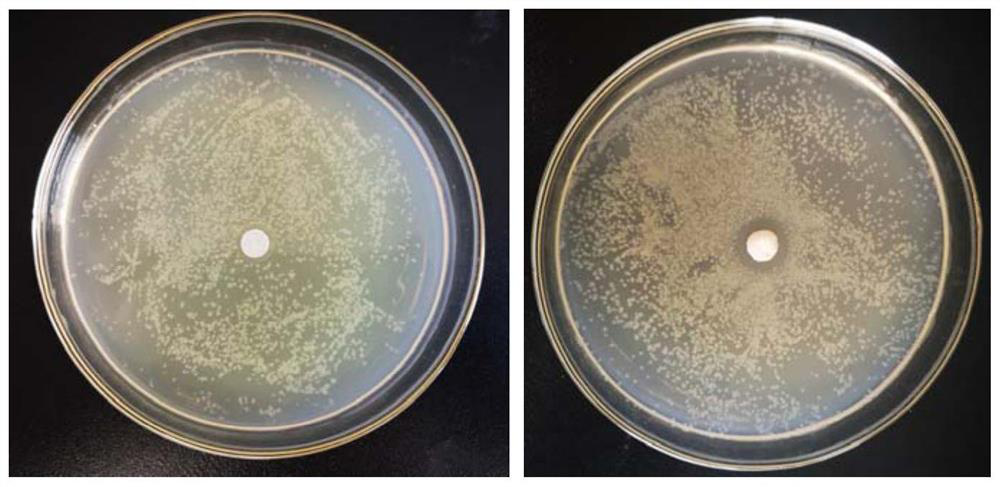

[0064] S3. Add 2 mmol / L nano-silver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com