Photocuring insulating lithium battery shell coating and preparation method thereof

A lithium battery and light curing technology, applied in the field of coatings, can solve the problems of large difference in total lithium content, low resistance, insufficient insulation performance, etc., and achieve the effects of improving efficiency, good modification effect and improving insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

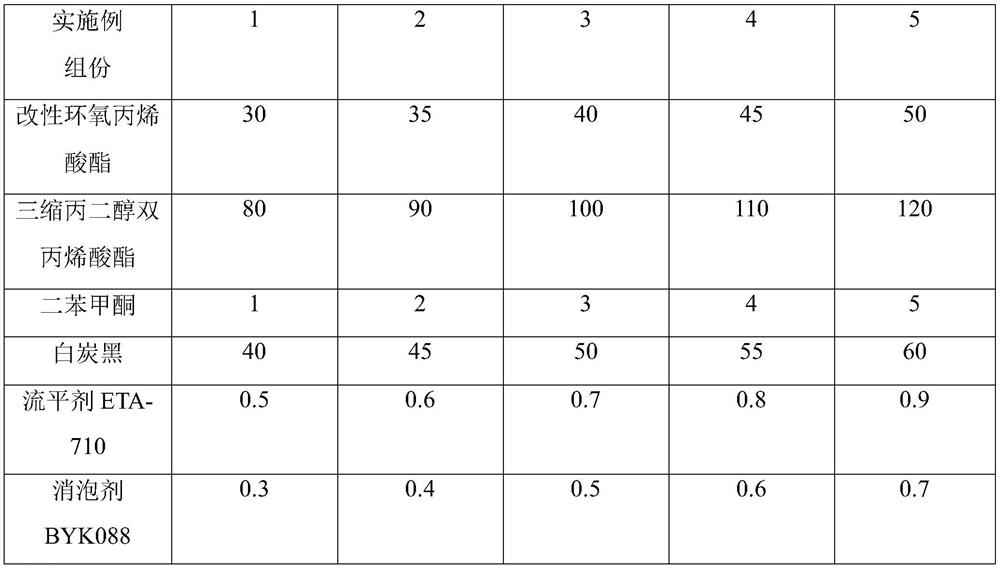

Examples

preparation example 1

[0045]A modified epoxy acrylate, the preparation method of which is as follows: adding 1 kg of aramid fiber nanofibers to 150 kg of acetone aqueous solution with a concentration of 20% by mass, mixing and stirring, and reacting at 80° C. for 100 min to obtain a mixed solution A; Add 100kg epoxy acrylate, 2kg phenol, 5kg silane coupling agent and 5kg catalyst to mixed solution A, mix and stir, react at 50°C for 2 hours to obtain mixed solution B, add mixed solution B to 600 kg of water, mix and stir for 20 min, filter Discard the filtrate to obtain modified epoxy acrylate;

[0046] Silane coupling agent is KH-550;

[0047] The catalyst is N,N-dimethylaniline.

preparation example 2-6

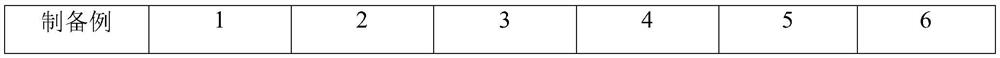

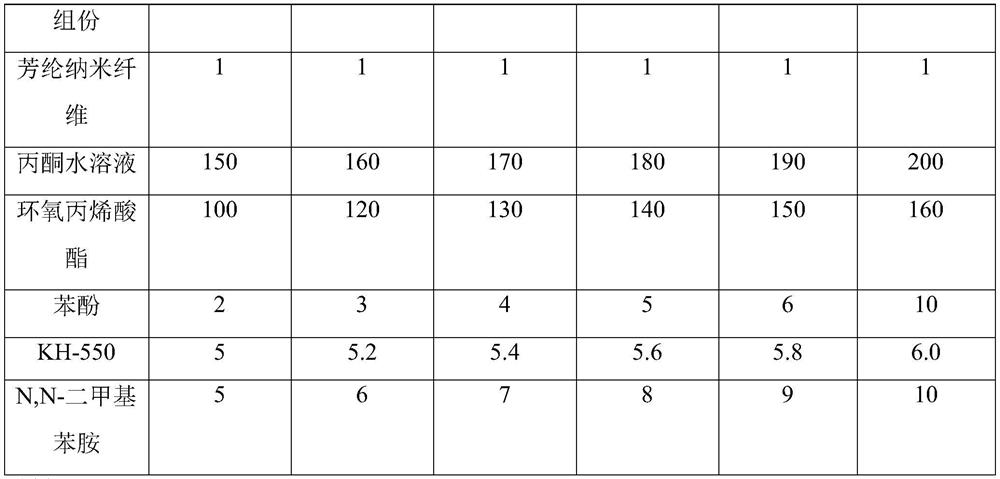

[0049] A modified epoxy acrylate is different from Preparation Example 1 in that the usage amount of each component is different, as shown in Table 1.

[0050] Components and their weights (kg) in Table 1 Preparation Examples 1-6

[0051]

[0052]

preparation example 7

[0054] A modified epoxy acrylate, the difference from Preparation Example 4 is that the aramid nanofibers are pretreated before being added to the acetone aqueous solution, and the specific treatment method is: adding 1kg of aramid nanofibers to 5kg of toluene for washing , filter and discard the filtrate, wash with 5kg of acetone aqueous solution with a mass percentage content of 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com