Straw mushroom culture material additive as well as preparation method and application thereof

A culture material and additive technology, applied in the field of straw mushroom culture material additives and preparation thereof, can solve the problems of uneven quality and reduction of waste cotton, and achieve the effects of improving growth activity, vigorous growth and increasing growth speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

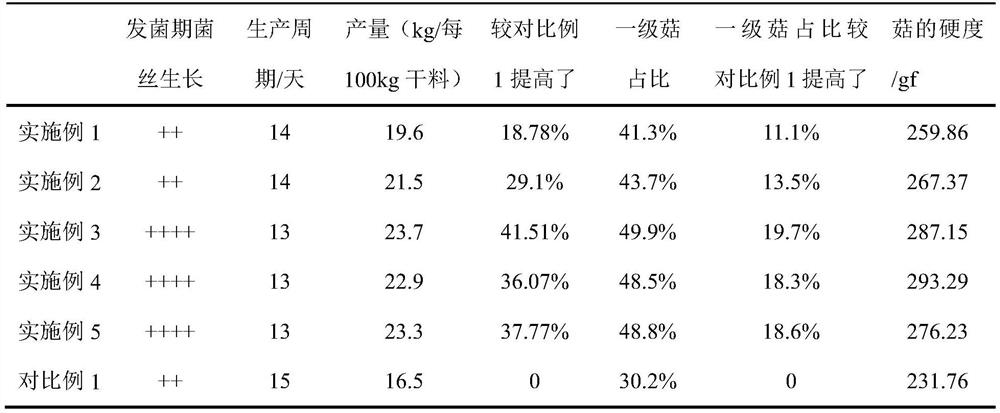

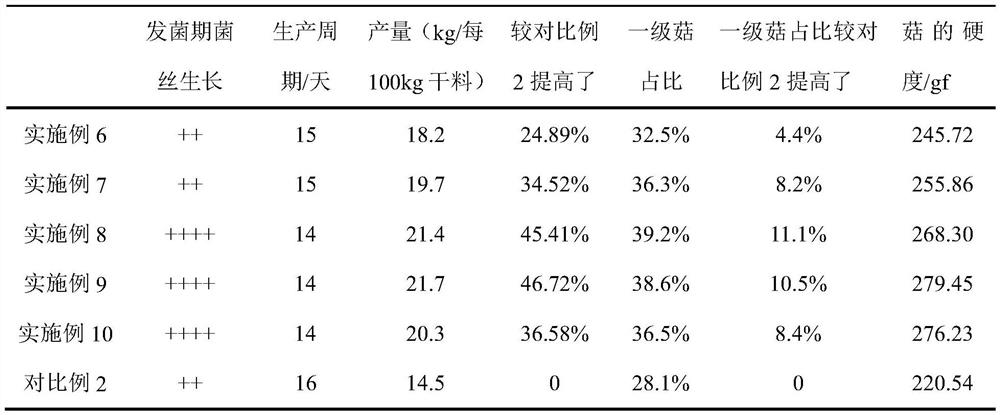

Examples

Embodiment 1

[0031] According to the following weight percentages, prepare 1000g of additives:

[0032] (1) 30.5% of soybean meal, 36.1% of corn gluten, 33.09% of bran, 0.1% of dipotassium hydrogen phosphate, 0.07% of sodium acetate, 0.004% of copper sulfate, 0.025% of zinc sulfate, and 0.035% of manganese sulfate are weighed according to the proportions. Mix.

[0033] (2) put the sample mixed according to the proportion in step (1) into a roasting machine, raise the temperature, and sterilize it by dry heat in an ordinary roasting machine at 140-145°C for 30 minutes. Store under vacuum.

[0034] (3) 0.05% of cellulase, 0.016% of pectinase, and 0.01% of protease are weighed according to the proportions and mixed for use.

[0035] (4) Mix the samples in step (2) and step (3).

[0036] (5) according to the method for comparative example 1, carry out straw mushroom cultivation; Wherein the additive mixed in the step (4) is mixed evenly with the nutrient material in the step (3) of comparat...

Embodiment 2

[0038] According to the following weight percentages, prepare 1000g of additives:

[0039] (1) 30.5% of soybean meal, 36.1% of corn gluten, 33.09% of bran, 0.1% of dipotassium hydrogen phosphate, 0.07% of sodium acetate, 0.004% of copper sulfate, 0.025% of zinc sulfate, and 0.035% of manganese sulfate are weighed according to the proportions. Mix.

[0040] (2) put the sample mixed according to the proportion in step (1) into a roasting machine, raise the temperature, and sterilize it by dry heat in an ordinary roasting machine at 140-145°C for 30 minutes. Store under vacuum.

[0041] (3) 0.05% of cellulase, 0.016% of pectinase, and 0.01% of protease are weighed according to the proportions and mixed for use.

[0042] (4) Mix the samples in step (2) and step (3).

[0043] (5) according to the method for comparative example 1, carry out straw mushroom cultivation; Wherein the additive mixed in the step (4) is mixed evenly with the nutrient material in the step (3) of comparat...

Embodiment 3

[0045] According to the following weight percentages, prepare 1000g of additives:

[0046] (1) 30.5% of soybean meal, 36.1% of corn gluten, 33.09% of bran, 0.1% of dipotassium hydrogen phosphate, 0.07% of sodium acetate, 0.004% of copper sulfate, 0.025% of zinc sulfate, and 0.035% of manganese sulfate are weighed according to the proportions. Mix.

[0047] (2) put the sample mixed according to the proportion in step (1) into a roasting machine, raise the temperature, and sterilize it by dry heat in an ordinary roasting machine at 140-145°C for 30 minutes. Store under vacuum.

[0048] (3) 0.05% of cellulase, 0.016% of pectinase, and 0.01% of protease are weighed according to the proportions and mixed for use.

[0049] (4) Mix the samples in step (2) and step (3).

[0050](5) according to the method for comparative example 1, carry out straw mushroom cultivation; Wherein the additive mixed in the step (4) is mixed evenly with the nutrient material in the step (3) of comparati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com