Brassica juncea pickled green vegetables and preparation method thereof

A technology of soaking green vegetables and powder stems, which is applied in the field of powder stem pickled vegetables and its preparation, which can solve the problems of unsatisfactory quality such as color, flavor, crispness, and sensory deterioration, and achieve high crispness and fermentation The effect of stable quality and extended shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

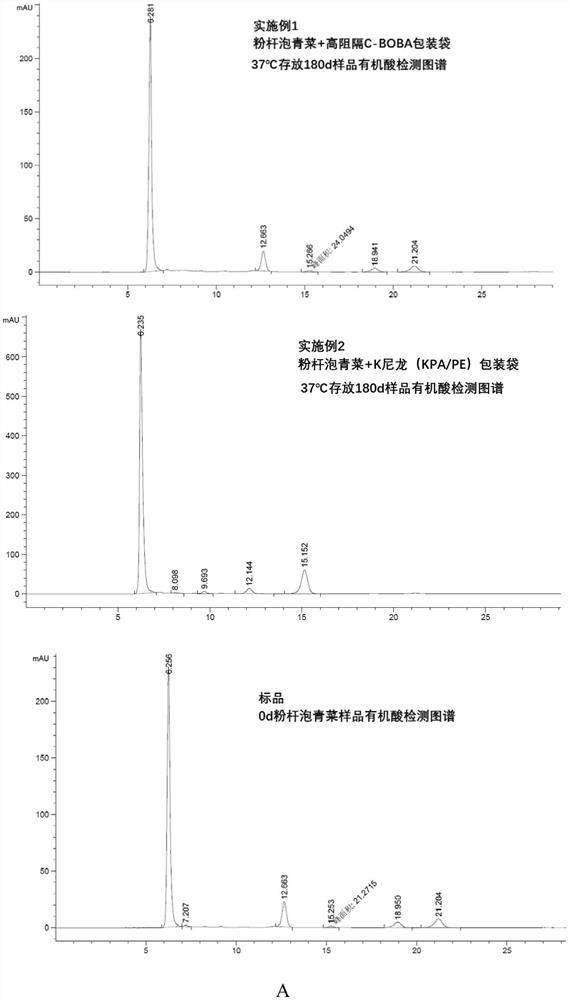

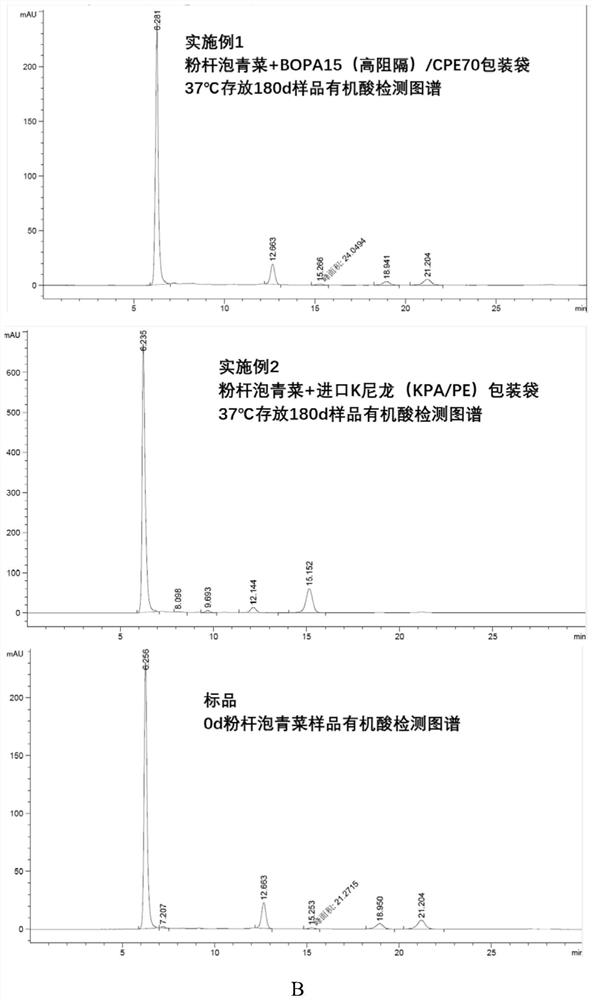

Embodiment 1

[0038] A preparation method of vermicelli pickled green cabbage, the specific process is as follows:

[0039] (1) Preparation of raw materials: choose fresh, good-quality vermicelli greens suitable for brewing, wash, and dry for use;

[0040] (2) Salting in the pool: For each 100kg of green vegetables, use 9kg of salt when salting. In the process of filling the pond, one layer of vegetables and one layer of salt are used. According to the weight of the fresh vegetables, 9kg of salt is used per 100kg of fresh vegetables at the bottom, middle and upper part of the pond, and the salt is required to be sprinkled evenly;

[0041] (3) Salt water circulation: From the day of entering the pool, the salt water circulation is carried out twice a day, each time is 3h, and the circulation time is 20 days;

[0042] (4) Fermentation by sealing the pool: Sprinkle the vegetable embryo with salt, spread it on the salt layer with a clean white tape, cover the white tape with a flower tape, and...

Embodiment 2

[0047] A preparation method of vermicelli pickled green cabbage, the specific process is as follows:

[0048] (1) Preparation of raw materials: choose fresh, good-quality vermicelli greens suitable for brewing, wash, and dry for use;

[0049] (2) Salting in the pond: For every 100kg of green vegetables, use 9kg of salt during salting. In the process of filling the pond, one layer of vegetables and one layer of salt are used. According to the weight of the fresh vegetables, 9kg of salt is used per 100kg of fresh vegetables at the bottom, middle and upper part of the pond, and the salt is required to be sprinkled evenly;

[0050] (3) Salt water circulation: From the day of entering the pool, the salt water circulation is carried out twice a day, each time is 3h, and the circulation time is 20 days;

[0051] (4) Fermentation by sealing the pool: Sprinkle the vegetable embryo with salt, spread it on the salt layer with a clean white tape, cover the white tape with a flower tape, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com