Preparation method and application of Janus membrane material for realizing on-demand separation of oil and water

A membrane material, oil-water technology, applied in separation methods, liquid separation, semi-permeable membrane separation, etc., to achieve high permeability and selective separation ability, good interface compatibility, and a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

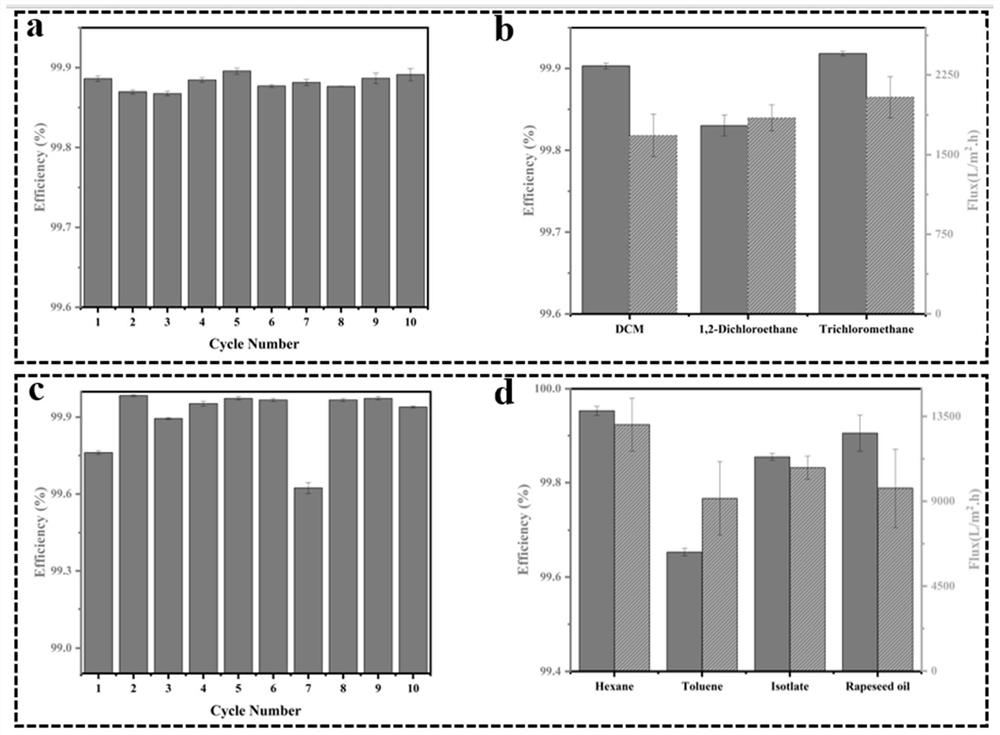

Examples

Embodiment 1

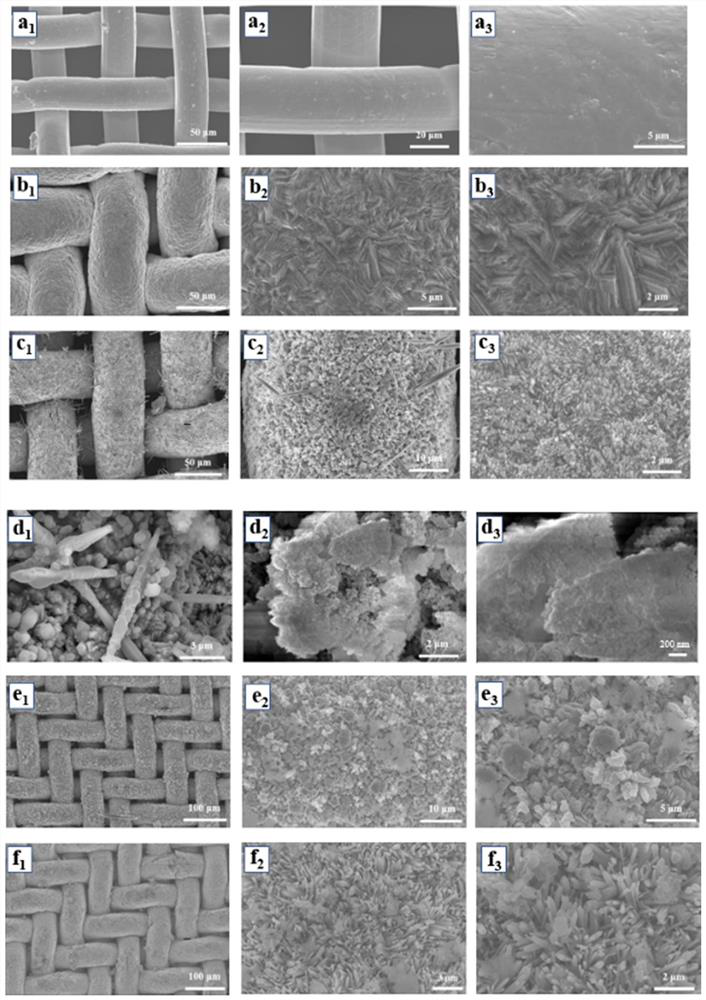

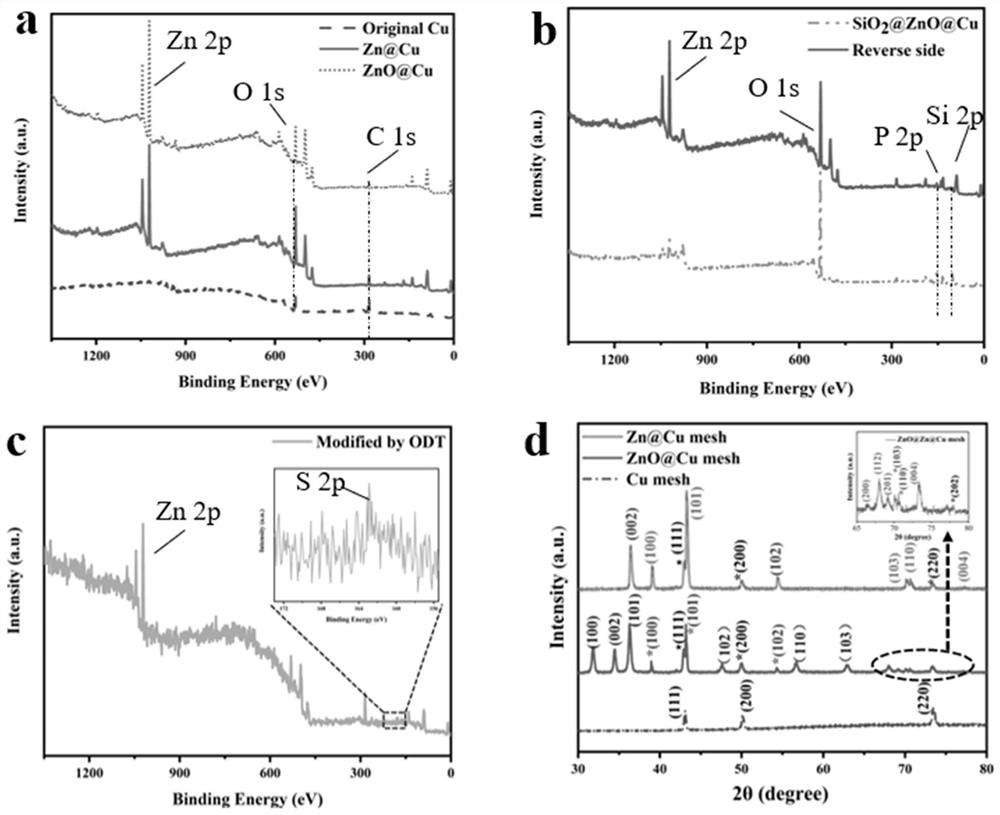

[0031] (1) Preparation of superhydrophilic ZnO@Zn@Cu meshes

[0032] The copper mesh was washed sequentially with acetone, ethanol and deionized water. Mix 5ml of concentrated sulfuric acid and 11g of ZnSO 4 Dissolve in 50ml of water, use the cleaned copper mesh as the cathode, the platinum sheet as the anode, set the power supply to constant current output mode, the current is 0.72A, immerse in the mixed solution for electrodeposition for 10min; then configure 0.006M Zn(NO 3 ) 2 , 2ml NH 3 ·H 2 O mixed solution, put the galvanized copper mesh together with the above solution into a reaction kettle, and hydrothermally react at 110 °C for 6 h to obtain a hydrophilic ZnO@Zn@Cu mesh;

[0033] (2) Preparation of Janus membrane

[0034] Mix aluminum hydroxide and phosphoric acid with a volume fraction of 60% in a ratio of 1:3, heat and stir at 100 °C for 3 hours, and cool to obtain an aluminum phosphate adhesive; mix 0.5 g of SiO 2Disperse into 15ml of ethanol and sonicate fo...

Embodiment 2

[0037] (1) Preparation of superhydrophilic ZnO@Zn@Cu meshes

[0038] The copper mesh was washed sequentially with acetone, ethanol and deionized water. Mix 5ml of concentrated sulfuric acid and 11g of ZnSO 4 Dissolve in 50ml of water, use the cleaned copper mesh as the cathode, the platinum sheet as the anode, set the power supply to constant current output mode, the current is 0.60A, immerse in the mixed solution for electrodeposition for 15min; then configure 0.006M Zn(NO 3 ) 2 , 2ml NH 3 ·H 2 O mixed solution, put the galvanized copper mesh together with the above solution into a reaction kettle, and hydrothermally react at 110 °C for 6 h to obtain a hydrophilic ZnO@Zn@Cu mesh;

[0039] (2) Preparation of Janus membrane

[0040] Mix aluminum hydroxide and phosphoric acid with a volume fraction of 60% in a ratio of 1:3, heat and stir at 100 °C for 3 hours, and cool to obtain an aluminum phosphate adhesive; mix 0.5 g of SiO 2 Disperse into 15ml of ethanol and sonicate f...

Embodiment 3

[0043] (1) Preparation of superhydrophilic ZnO@Zn@Cu meshes

[0044] The copper mesh was washed sequentially with acetone, ethanol and deionized water. Mix 5ml of concentrated sulfuric acid and 11g of ZnSO 4 Dissolve in 50ml of water, use the cleaned copper mesh as the cathode, the platinum sheet as the anode, set the power supply to constant current output mode, the current is 0.72A, immerse in the mixed solution for electrodeposition for 10min; then configure 0.006M Zn(NO 3 ) 2 , 2ml NH 3 ·H 2 O mixed solution, put the galvanized copper mesh together with the above solution into a reaction kettle, and hydrothermally react at 110 °C for 6 h to obtain a hydrophilic ZnO@Zn@Cu mesh;

[0045] (2) Preparation of Janus membrane

[0046] Mix aluminum hydroxide and phosphoric acid with a volume fraction of 60% in a ratio of 1:3, heat and stir at 100 °C for 3 hours, and cool to obtain an aluminum phosphate adhesive; mix 0.5 g of SiO 2 Disperse into 15ml of ethanol and sonicate f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com