Preparation method of cyano-modified compounded carbon-based polyaryl ether nitrile composite material

A polyarylene ether nitrile and composite material technology, which is applied in the field of dielectric thin film materials, can solve the problems of rare research on dielectric properties, poor interface compatibility and high dielectric loss, and improve stability and processability. , Good interfacial compatibility, and the effect of improving heat resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

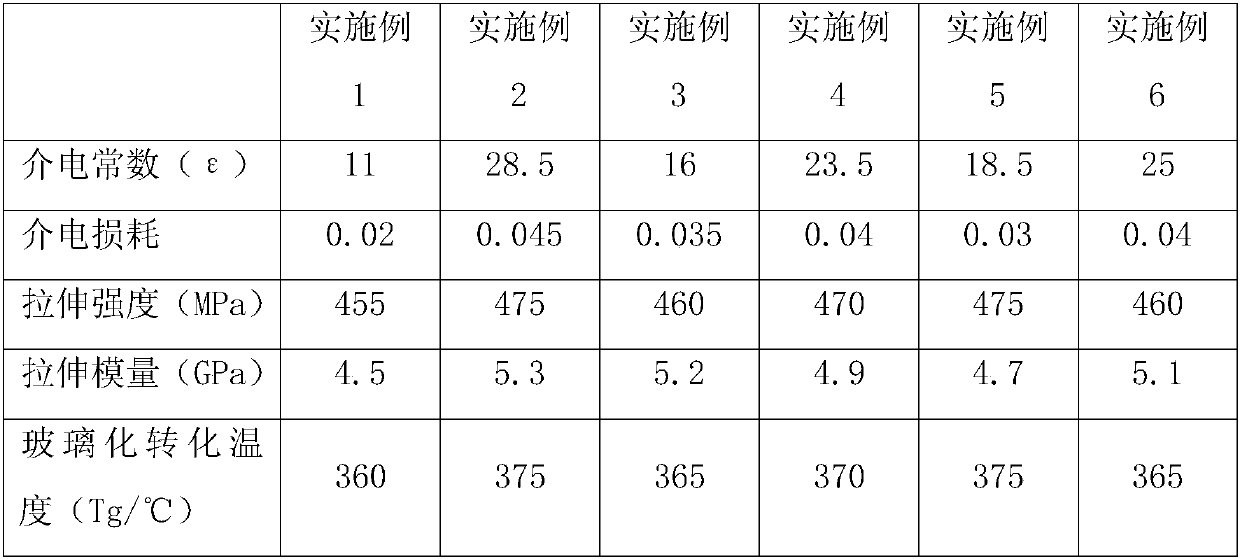

Examples

Embodiment 1

[0026] (1) Add 0.2g graphene oxide into 200mL thionyl chloride and stir ultrasonically, under the catalysis of N,N-dimethylformamide, heat and reflux at 60°C for 24h, filter and vacuum dry to obtain acyl chloride graphene , with excess aminophenoxyphthalonitrile and cyano-modified cellulose derivatives, added to toluene solvent, stirred and refluxed at room temperature for 72h, washed and centrifuged and dried to obtain cyano-functionalized graphene / fiber Plain composite material, wherein the content of cellulose is higher than 50wt%.

[0027] (2) Use the cyano-functionalized graphene / cellulose composite material as the carbon source, and use 5wt% ferrocene as the catalyst precursor. Under nitrogen atmosphere, first react at 400°C for 30min, then heat up to 900°C for reaction 5min, high-temperature carbonization to obtain a cyano-functionalized graphene-containing composite carbon material.

[0028] (3) The cyano-functionalized graphene-containing composite carbon material is...

Embodiment 2

[0031] (1) Add 0.3g of graphene oxide into 200mL of thionyl chloride and stir ultrasonically, under the catalysis of N,N-dimethylformamide, heat and reflux at 70°C for 24h, filter and dry in vacuum to obtain acyl chloride graphene , with excess aminophenoxyphthalonitrile and cyano-modified cellulose derivatives, added to toluene solvent, stirred and refluxed at room temperature for 72h, washed and centrifuged and dried to obtain cyano-functionalized graphene / fiber Plain composite material, wherein the content of cellulose is higher than 50wt%.

[0032] (2) Use the cyano-functionalized graphene / cellulose composite material as the carbon source, use 30wt% ferrocene as the catalyst precursor, and react at 450°C for 40min under nitrogen atmosphere, then heat up to 900°C for reaction 15min, high-temperature carbonization to obtain a cyano-functionalized graphene-containing composite carbon material.

[0033] (3) The cyano-functionalized graphene-containing composite carbon materia...

Embodiment 3

[0036] (1) Add 0.25g of graphene oxide into 200mL of thionyl chloride and stir ultrasonically, under the catalysis of N,N-dimethylformamide, heat and reflux at 65°C for 24h, filter and vacuum dry to obtain acyl chloride graphene , with excess aminophenoxyphthalonitrile and cyano-modified cellulose derivatives, added to toluene solvent, stirred and refluxed at room temperature for 72h, washed and centrifuged and dried to obtain cyano-functionalized graphene / fiber Plain composite material, wherein the content of cellulose is higher than 50wt%.

[0037] (2) Use the cyano-functionalized graphene / cellulose composite material as a carbon source, and use 10wt% ferrocene as a catalyst precursor. Under a nitrogen atmosphere, first react at 420°C for 35min, then heat up to 900°C for reaction 10min, high-temperature carbonization to obtain a cyano-functionalized graphene-containing composite carbon material.

[0038] (3) The cyano-functionalized graphene-containing composite carbon materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com