Phosphorus-containing polyethylene polyamine flame retardant and preparation method thereof

A polyethylene polyamine and flame retardant technology, which is applied in the field of halogen-free flame retardant, can solve the problems of complex preparation process and low flame retardant efficiency, and achieves simple preparation method, improved flame retardant performance, improved weather resistance and mechanical performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Place 4.68 grams of polyethylene polyamine, 11.75 grams of potassium carbonate, 9.72 grams of tripropylamine and 40 milliliters of tetrahydrofuran in a three-necked flask, and add 27.40 grams of diphenyl chlorophosphate dropwise at 0°C under nitrogen, and the addition is complete Afterwards, the reaction was continued for 1 hour at 0°C and under nitrogen, then the temperature was raised to 30°C, and the reaction was carried out under nitrogen for 24 hours. Finally, the obtained product was filtered to remove the precipitate and then the solvent was removed. The obtained light yellow colloid was the phosphorus-containing polysaccharide Ethylene polyamine flame retardant.

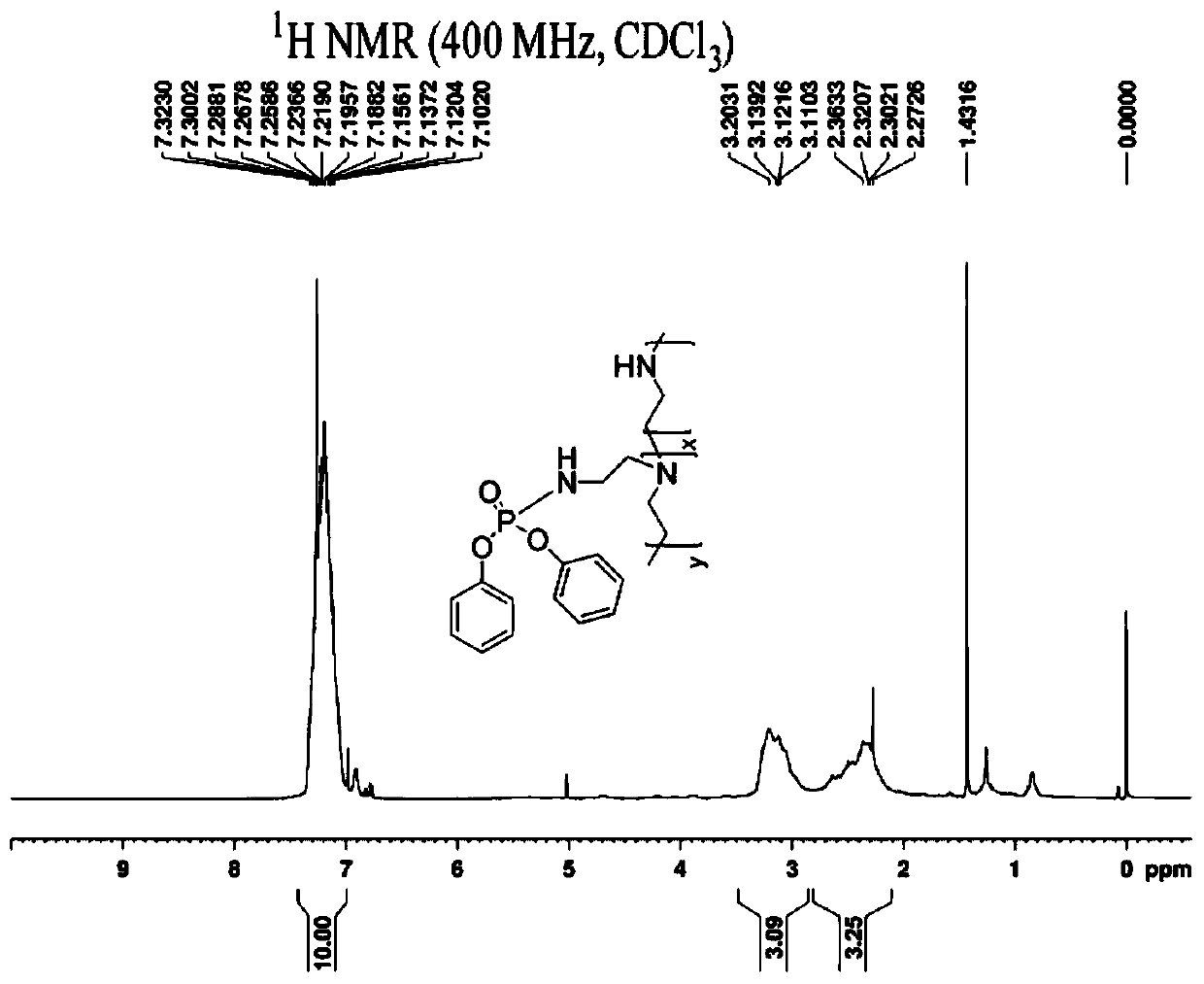

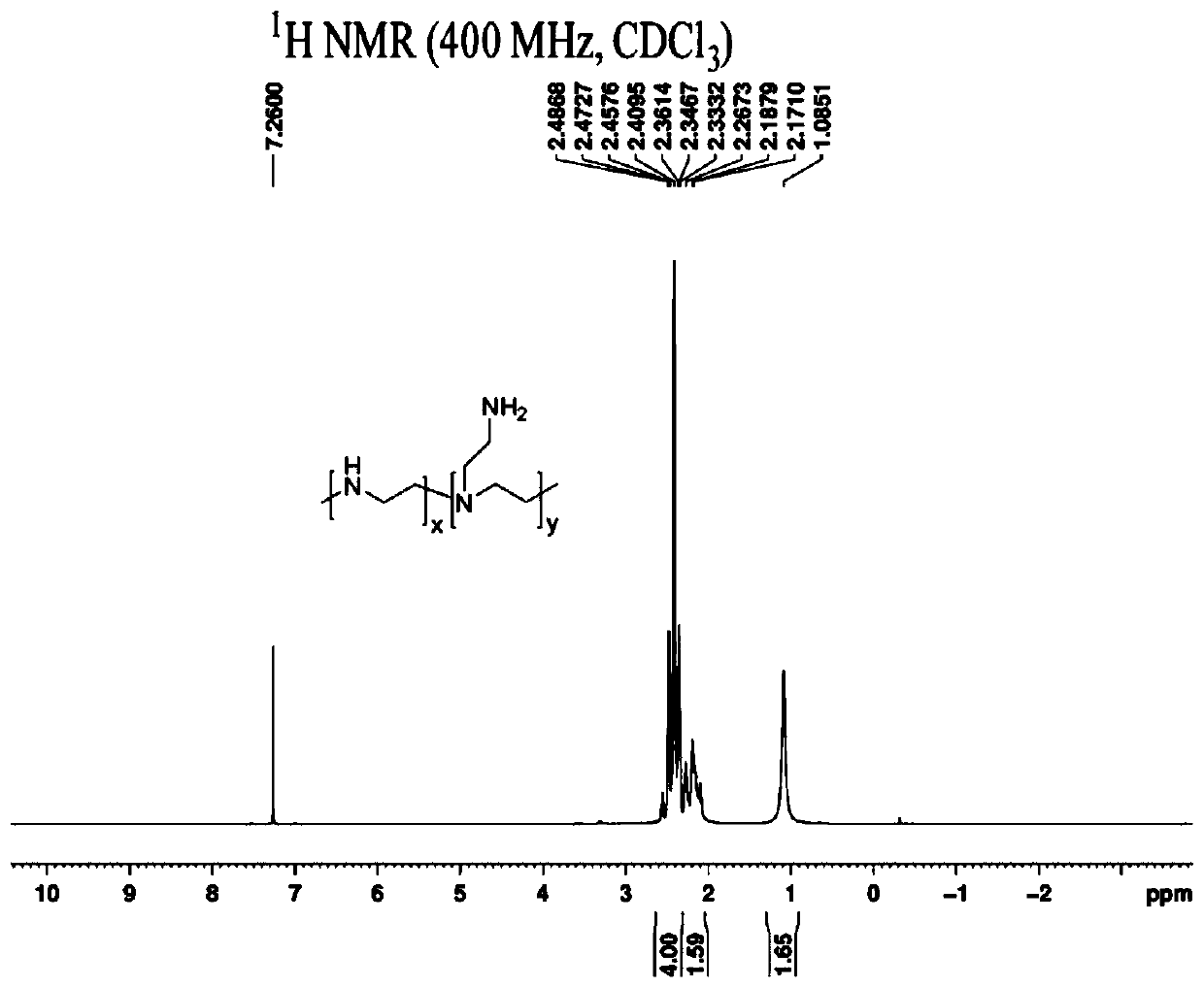

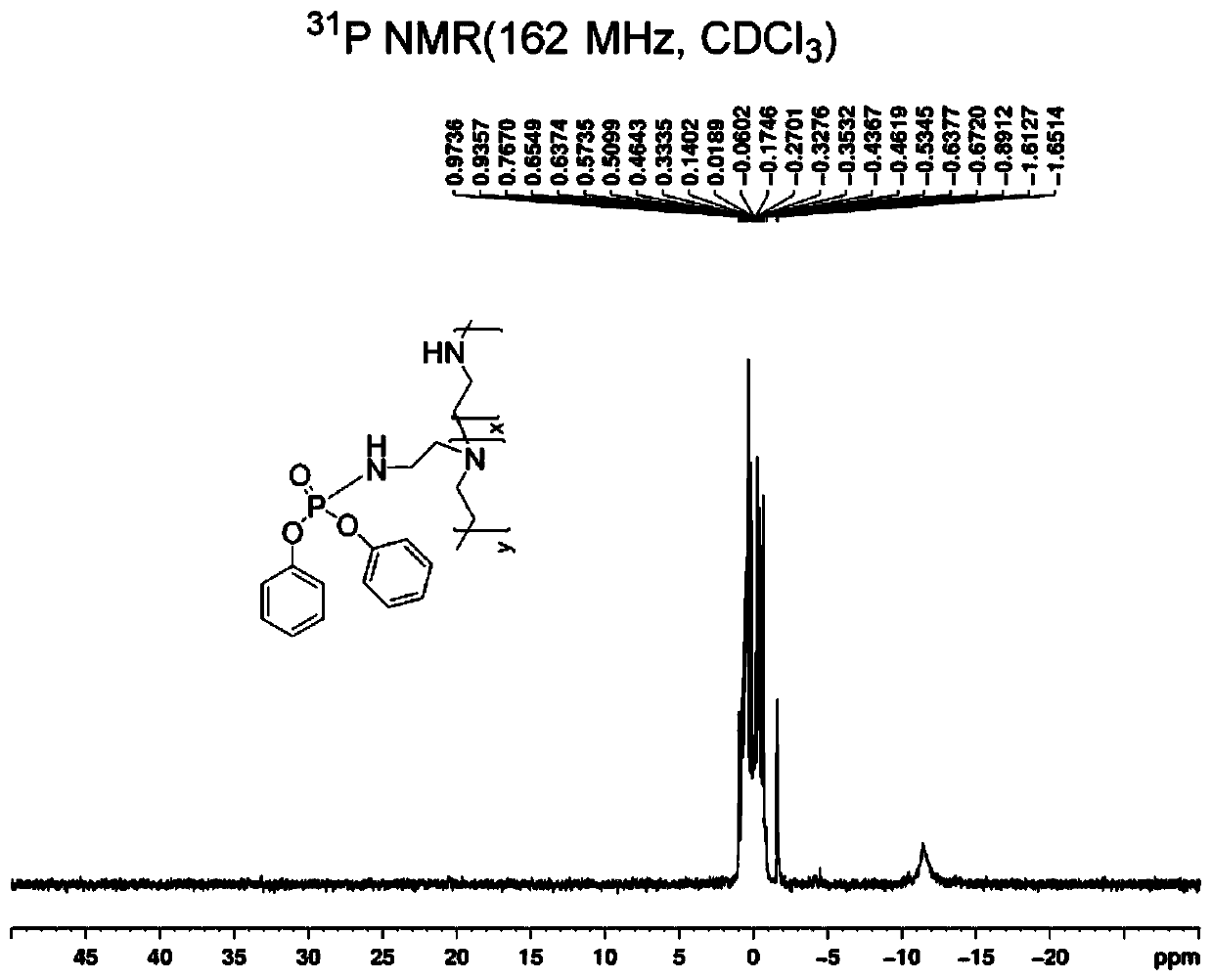

[0023] figure 1 and figure 2 Respectively the target product prepared in embodiment 1 and the proton nuclear magnetic resonance spectrum of raw material polyethylene polyamine used 1 H NMR (400MHz, CDCl 3 ). From figure 1 and figure 2 It can be seen that the most significant difference between ...

Embodiment 2

[0026] Put 1.38 grams of polyethylene polyamine, 0.82 grams of sodium acetate, 1.23 grams of N-methylimidazole and 10 milliliters of 1,4-dioxane in a three-necked flask, and add 2.11 grams of After the addition of diethylphosphorous oxychloride, continue to react at 1°C and nitrogen for 1.5 hours, then raise the temperature to 35°C, and react for 12 hours under nitrogen, and finally filter the obtained product to remove the precipitate and remove the solvent. The yellow colloid is the phosphorus-containing polyethylene polyamine flame retardant of the present invention.

Embodiment 3

[0028] 13.75 grams of polyethylene polyamine, 15.90 grams of sodium carbonate, 16.42 grams of N-methylimidazole and 120 milliliters of dichloromethane were placed in a three-necked flask, and 47.33 grams of diphenylphosphine were added dropwise at 2°C under nitrogen. Acyl chloride, after the dropwise addition, continue to react at 2°C and nitrogen for 2 hours, then raise the temperature to 40°C, and react under nitrogen for 36 hours, and finally filter the product to remove the precipitate and remove the solvent, and the obtained light yellow colloid is the base Invented phosphorus-containing polyethylene polyamine flame retardant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com