Phenol-acetone preparation process based on KBR technology

A phenol acetone and preparation process technology, applied in the field of phenol acetone preparation technology based on KBR technology, can solve the problems of unutilized waste, unfavorable enterprise benefit, low product selectivity, etc., and achieves reduction of preparation cost, guarantee of enterprise benefit, extraction Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

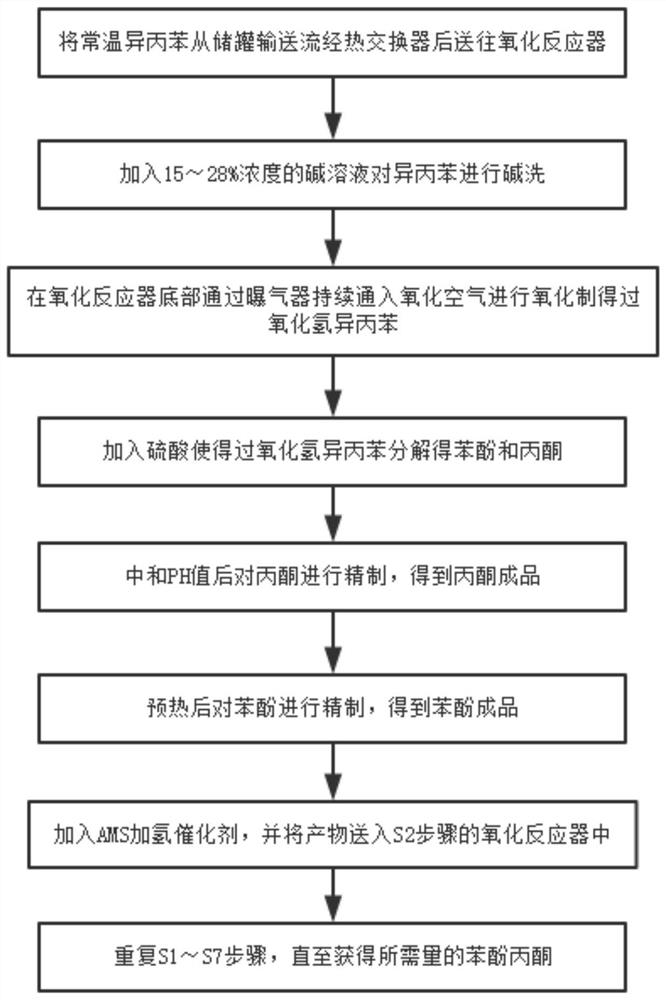

Image

Examples

Embodiment 1

[0034] A kind of phenol acetone preparation technology based on KBR technology, comprises the following steps successively:

[0035] S1: The normal temperature cumene is transported from the storage tank through the heat exchanger and then sent to the oxidation reactor;

[0036] S2: adding alkali solution of 15-28% concentration to carry out alkali washing on cumene;

[0037] S3: at the bottom of the oxidation reactor, the oxidizing air is continuously fed through the aerator for oxidation to obtain cumene hydrogen peroxide;

[0038] S4: adding sulfuric acid to decompose cumene hydrogen peroxide to obtain phenol and acetone;

[0039] S5: after neutralizing the pH value, acetone is purified to obtain the acetone finished product;

[0040] S6: refining the phenol after preheating to obtain a finished phenol product;

[0041] S7: add AMS hydrogenation catalyst, and send the product into the oxidation reactor of step S2;

[0042] S8: Repeat steps S1 to S7 until the required am...

Embodiment 2

[0047] A kind of phenol acetone preparation technology based on KBR technology, comprises the following steps successively:

[0048] S1: The normal temperature cumene is transported from the storage tank through the heat exchanger and then sent to the oxidation reactor;

[0049] S2: adding 20% concentration of alkali solution to carry out alkali washing to cumene;

[0050] S3: at the bottom of the oxidation reactor, the oxidizing air is continuously fed through the aerator for oxidation to obtain cumene hydrogen peroxide;

[0051] S4: adding sulfuric acid to decompose cumene hydrogen peroxide to obtain phenol and acetone;

[0052] S5: after neutralizing the pH value, acetone is purified to obtain the acetone finished product;

[0053] S6: refining the phenol after preheating to obtain a finished phenol product;

[0054] S7: add AMS hydrogenation catalyst, and send the product into the oxidation reactor of step S2;

[0055] S8: Repeat steps S1 to S7 until the required amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com