Separation equipment and process method for purifying high-purity EPA-ee from fish oil

A separation device and high-purity technology, applied in the field of purifying high-purity EPA-ee in fish oil, can solve the problems of complex unsaturated fatty acid composition, low EPA purity, and high production cost, and achieve low concentration cost, high EPA yield, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

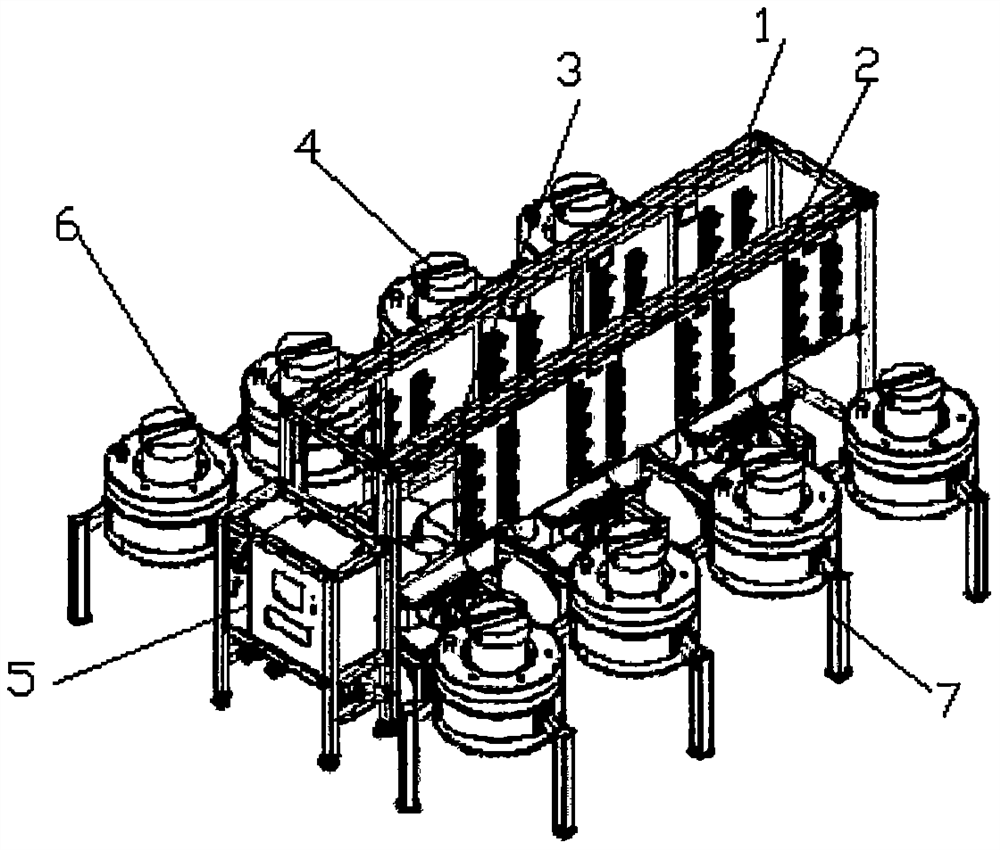

[0030] see figure 1 , according to a kind of separation equipment for purifying high-purity EPA-ee from fish oil according to an embodiment of the present invention, comprising an external fixing frame 1, the fixing frame 1 is provided with an infusion pump system 2, and the infusion pump system 2 is provided with In the valve control system 3 , four chromatographic columns 4 are symmetrically arranged on both sides of the fixed frame 1 , and an online monitoring device 5 is arranged at one end of the fixed frame 1 .

[0031] A kind of processing method of purifying high-purity EPA-ee from fish oil, is characterized in that, step is as follows:

[0032] S1: The low-content EPA-ee raw material needs to be purified to more than 60% by molecular distillation and other schemes;

[0033] S2: the ratio of regeneration liquid is 95%-100% methanol water, further 97-100% methanol water, and further 100% methanol water;

[0034] S3: the eluent ratio is 85%-95% methanol water, further ...

Embodiment 2

[0042] like figure 1 As shown, the bottom of the chromatographic column 4 is provided with support legs 7, which play a supporting role.

Embodiment 3

[0044] like figure 1 As shown, the online monitoring device 5 includes a control cabinet 6, which facilitates the overall control and real-time monitoring of the equipment.

[0045] In order to facilitate the understanding of the above technical solutions of the present invention, the working principle or operation mode of the present invention in the actual process will be described in detail below.

[0046] In practical application, the low content EPA-ee raw material needs to be purified to more than 60% through molecular distillation and other schemes. The purification process only uses methanol and water solvent, and the recovery and application are simple. The particle size of C18 filler is 10-50μm , a further 10-15μm, a further 15μm, the reversed-phase silica packing used in the super preparation has a good separation effect, the GMP / FDA certification is simple, and can be reused, the environmental pollution is small, the super chromatography purification process is fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com