Method for crystallizing long-chain dicarboxylic acid and method for purifying long-chain dicarboxylic acid

A long-chain dicarboxylic acid and refining method technology, applied in the field of long-chain dicarboxylic acid refining, can solve problems such as inability to induce crystallization, lower production efficiency, and uncertain operation of crystallization control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

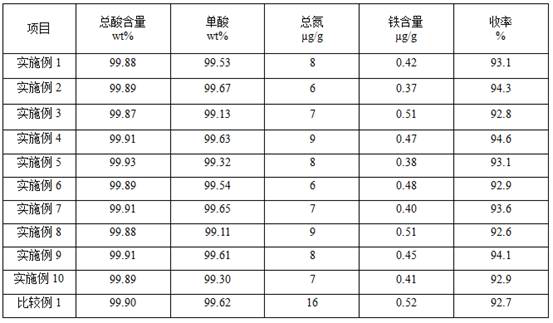

Examples

Embodiment 1

[0046] 1, the fermented liquid containing decanedicarboxylic acid is filtered to remove solid impurities such as thalline;

[0047] II, in the product of I, add sulfuric acid, make dodecanedicarboxylic acid to separate out, filter to obtain dodecanedicarboxylic acid filter cake crude product;

[0048] III. In a 100L dissolving kettle, drop into 50 liters of acetic acid, drop into 25kg of crude dodecanedicarboxylic acid, be warming up to 84° C., heat preservation and stirring to fully dissolve the dibasic acid, and the solution enters the decolorization kettle after being clarified by a 0.1 μm aperture filter. Activated carbon 0.28kg was added to the decolorization kettle, stirred evenly, adsorbed at 82°C for 30 minutes, the decolorization solution passed through 10 μm and 0.2 μm filters in turn, and the dodecanedicarboxylic acid solution entered the crystallization kettle.

[0049] Ⅳ. Turn on the cooling system of the crystallization kettle, cool the solution to be crystallize...

Embodiment 2

[0052] 1. The fermentation broth containing dodecanedicarboxylic acid is filtered, and solid impurities such as bacterial cells are removed;

[0053] II, in the product of I, add sulfuric acid, make dodecanedicarboxylic acid to separate out, filter to obtain dodecanedicarboxylic acid filter cake crude product;

[0054] III. In a 100L dissolving kettle, drop into 58 liters of acetic acid, drop into 26 kg of dodecanedicarboxylic acid crude product, be warming up to 86° C., heat preservation and stirring to fully dissolve the dibasic acid, and the solution enters the decolorizing kettle after being clarified by a 0.1 μm aperture filter. Add 0.39kg of activated carbon to the decolorization kettle, stir evenly, absorb at 83°C for 30 minutes, the decolorization solution passes through 10 μm and 0.2 μm filters in turn, and the dodecanedicarboxylic acid solution enters the crystallization kettle.

[0055] Ⅳ. Turn on the cooling system of the crystallization kettle, cool the solution t...

Embodiment 3

[0058] 1, by filtering the fermentation broth containing tridecanedicarboxylic acid, remove solid impurities such as thalline;

[0059] II, in the product of I, add sulfuric acid, make tridecanedicarboxylic acid to separate out, filter to obtain tridecanedicarboxylic acid filter cake crude product;

[0060] III. In a 100L dissolving kettle, drop into 55 liters of acetic acid, drop into 24 kg of tridecanedicarboxylic acid crude product, be warming up to 84° C., heat preservation and stirring to fully dissolve the dibasic acid, and the solution enters the decolorizing kettle after being clarified by a 0.1 μm aperture filter. Add 0.30kg of activated carbon to the decolorization kettle, stir evenly, adsorb at 80°C for 30 minutes, the decolorization solution passes through 10 μm and 0.2 μm filters in turn, and the tridecanedicarboxylic acid solution enters the crystallization kettle.

[0061] Ⅳ. Turn on the cooling system of the crystallization kettle, cool the solution to be cryst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com