Antibacterial conductive composite film for water treatment as well as preparation method and application of antibacterial conductive composite film

A composite membrane and water treatment technology, which is applied in the field of water treatment, can solve the problems of membrane flux decrease and electrostatic effect failure, etc., and achieve the effects of overcoming poor sustainability, improving service life and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

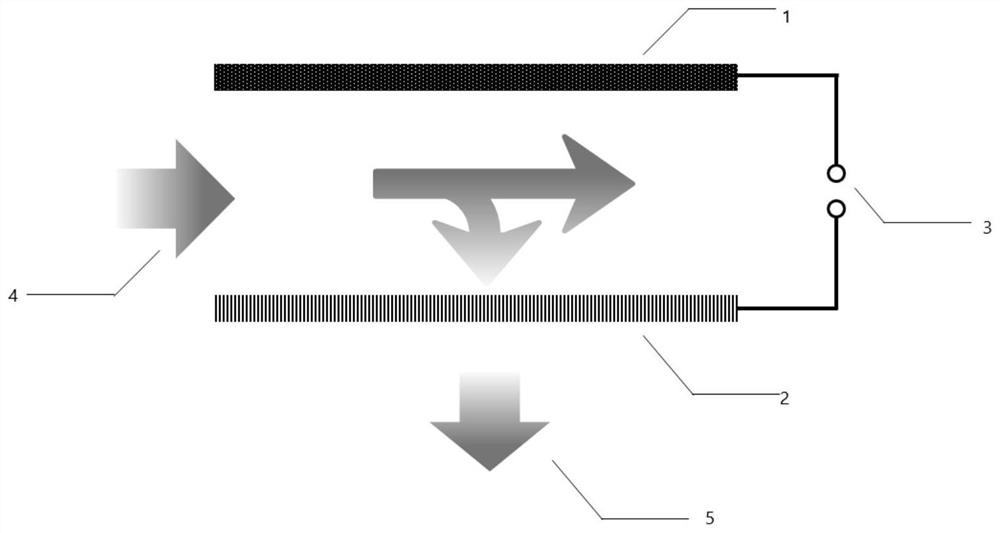

Image

Examples

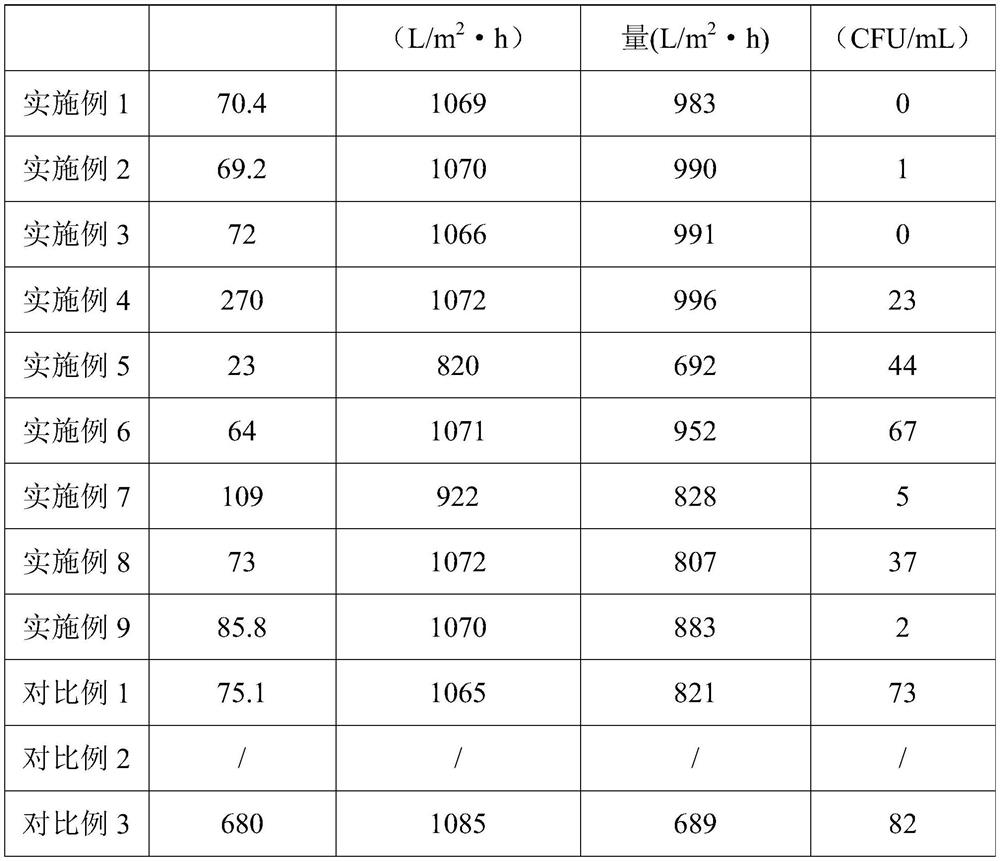

Embodiment 1

[0044] An antibacterial conductive composite membrane for water treatment, the antibacterial conductive composite membrane is composed of a polytetrafluoroethylene membrane (Millipore, 100 nm) and an antibacterial conductive layer disposed on the surface of the polytetrafluoroethylene membrane;

[0045] The materials of the antibacterial conductive layer include polypyrrole, 3-chloro-2-hydroxypropyltrimethylammonium chloride and sodium dodecylbenzenesulfonate, wherein polypyrrole and 3-chloro-2-hydroxypropyl The mass ratio of trimethylammonium chloride is 1:3;

[0046] The preparation method of the antibacterial conductive composite membrane for water treatment provided by this embodiment includes the following steps:

[0047] (1) Immerse the polytetrafluoroethylene film in 1 mol / L of ferric chloride, 0.0025 mol / L of sodium dodecylbenzenesulfonate and 0.0025 mol / L of 3-chloro-2-hydroxypropyltrimethyl in the mixed aqueous solution of ammonium chloride for 30min to obtain the s...

Embodiment 2

[0050] An antibacterial conductive composite membrane for water treatment, the only difference from Example 1 is that the mass ratio of polypyrrole and 3-chloro-2-hydroxypropyltrimethylammonium chloride is 1:1, and other parameters and steps are the same as in Example 1.

Embodiment 3

[0052] An antibacterial conductive composite membrane for water treatment, the only difference from Example 1 is that the mass ratio of polypyrrole and 3-chloro-2-hydroxypropyltrimethylammonium chloride is 1:5, and other parameters and steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com