Preparation method of centrifugal hydrogel liquid drops

A hydrogel and centrifugal technology, applied in biochemical equipment and methods, tissue culture, microorganisms, etc., can solve the problem of flux, cost, simplicity, lack of uniformity and safety of hydrogel droplets and other issues, to achieve high-throughput repeatability, easy industrial mass production customization, and reduce consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Preparation of hydrogel droplets

[0032] A method for preparing centrifugal hydrogel droplets, comprising the steps of:

[0033] 1) Preparation of hydrogel and oil phase

[0034] One or two or more biomacromolecular compounds are selected from GelMA, sodium alginate, and agarose to be compounded into a hydrogel of corresponding mass fraction (or viscosity);

[0035] Mix 1-20 parts: 99-80 parts of EM 180 emulsifier and isopropyl palmitate respectively by volume to obtain an oil phase with certain surface tension and viscosity.

[0036] 2) Preparation of hydrogel droplets

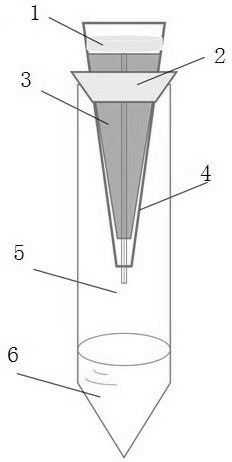

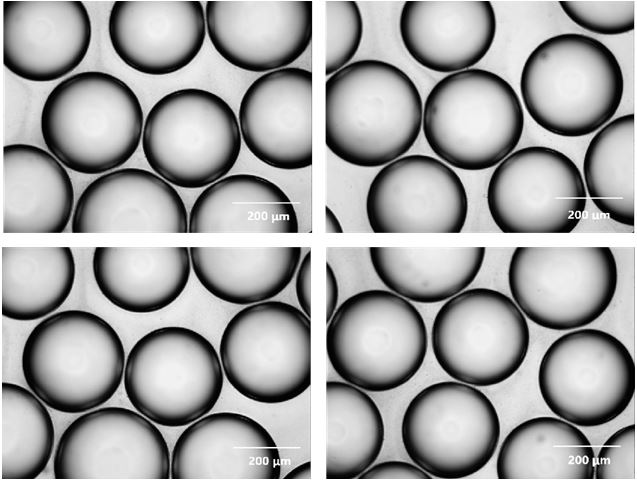

[0037] figure 1 As shown, use PDMS 3 to place capillary 5 (greater than 30 μm in diameter) in a 200 μL pipette tip 4, and fix the pipette tip with capillary in the center of a 15 mL centrifuge tube by snap 2. The centrifuge tube is filled with 5~10 mL of oil phase 6 prepared in step 1), and is used as a container for collecting hydrogel droplets to prevent droplets from being thrown to t...

Embodiment 2

[0038] Example 2 Preparation of cell-loaded hydrogel droplets

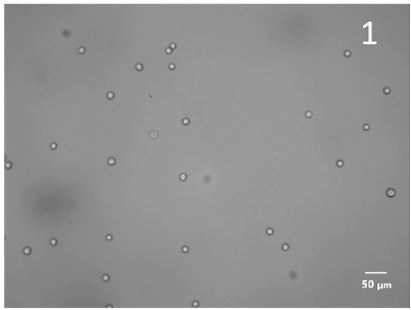

[0039] The alternative cells cultured in 2D mode were collected by centrifugation and enzymatically digested to obtain monodisperse cells ( Figure 3.1-3.3 , Figure 4.1-4.3 ) to prepare different numbers of cell solutions. Take the hydrogel prepared in step 1) in Example 1, add 10-1000 cells per 1.0 mL of hydrogel, and add 50-500 μL of sample to the pipette tip of the centrifugal device after mixing. The cells were incubated at 37 °C for 1–5 min, and centrifuged at 100–3000 RCF for 1–5 min to produce a hydrogel solution loaded with cells, and the hydrogel droplets containing cells could be identified under a fluorescence optical microscope ( Figure 3.4 and Figure 4.4 ). Encapsulation of cells in hydrogel droplets can be better illustrated using GFP-bearing cells.

[0040] The above-mentioned centrifugal method for preparing hydrogel droplets loaded with living cells is simple and easy to implement, does no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com