Preparation method of photo-thermal super-hydrophobic deicing coating

A super-hydrophobic and coating technology, which is applied in coatings, chemical instruments and methods, and devices for coating liquids on surfaces, can solve problems such as low efficiency, environmental damage, and high energy consumption, and achieve increased surface roughness, delay The effect of freezing water droplets and reducing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A preparation method of a photothermal superhydrophobic deicing coating mainly comprises the following steps:

[0024] The first step, pretreatment of aluminum sheet: use sandpaper to remove the uneven oxide layer on the surface of the aluminum sheet, ultrasonically clean it with ethanol for 5-10 minutes, and then dry it for later use.

[0025] In the second step, drop the polytetrafluoroethylene suspension into a beaker containing amyl acetate solvent, and ultrasonicate for 5-10min to make it evenly mixed; the mass ratio of the polytetrafluoroethylene suspension to amyl acetate is 1:1-2 .

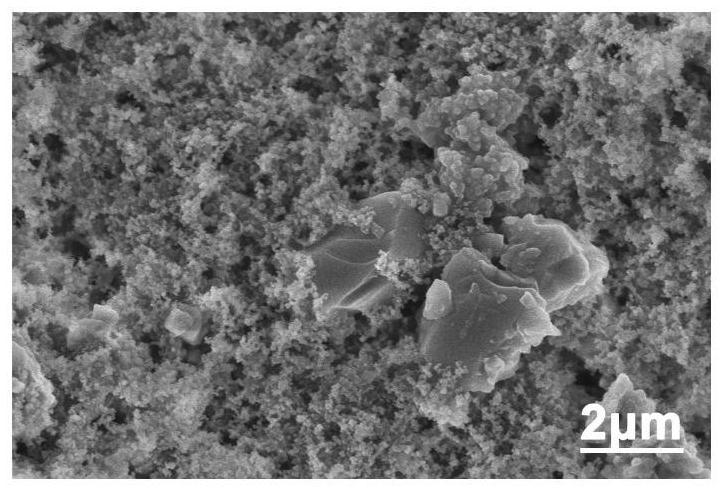

[0026] In the third step, add Prussian blue and hydrophobic silica into the beaker in turn, stir for 6-24h, and the precursor solution is prepared; the contents of Prussian blue and hydrophobic silica are respectively PTFE suspension and pentyl acetate 1-5% of total ester mass.

[0027] The fourth step is to spray the precursor solution onto the surface of the pretreated aluminum ...

Embodiment 1

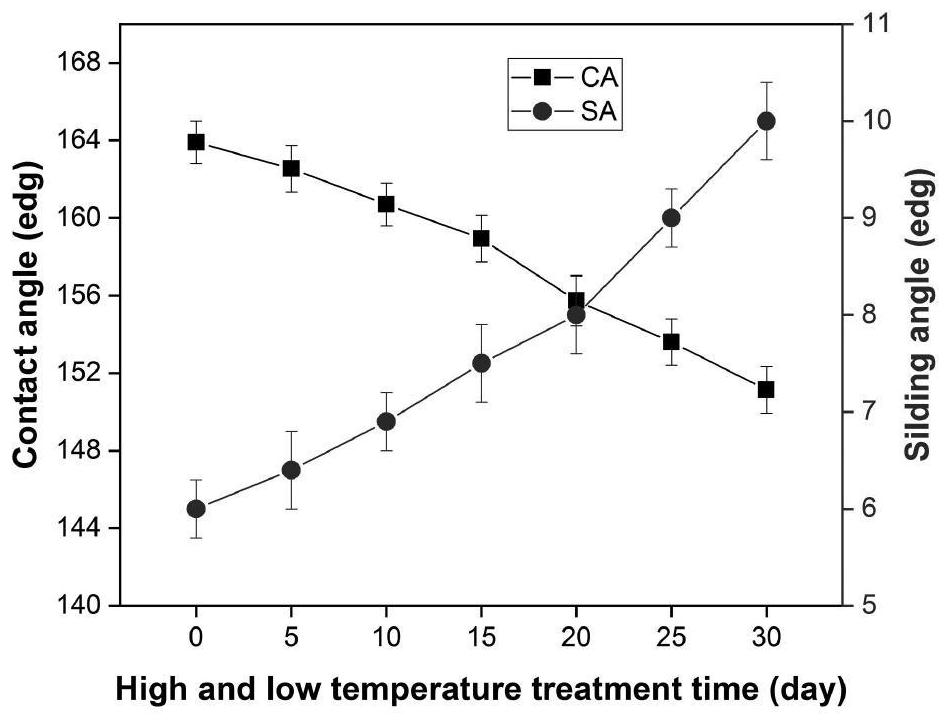

[0035] In this embodiment, in the third step, the content of Prussian blue is 3% of the total mass of the polytetrafluoroethylene suspension and amyl acetate, and the content of hydrophobic silica is the total mass of the polytetrafluoroethylene suspension and amyl acetate. 1% of the mass, the prepared precursor solution was sprayed onto the surface of the pretreated aluminum sheet, the contact angle of the water droplet was 163.6±1.5°, and the rolling angle was 8±0.4°.

Embodiment 2

[0037] In this embodiment, in the third step, the content of Prussian blue is 3% of the total mass of the polytetrafluoroethylene suspension and amyl acetate, and the content of hydrophobic silica is the total mass of the polytetrafluoroethylene suspension and amyl acetate. 2% of the mass, the prepared precursor solution was sprayed onto the surface of the pretreated aluminum sheet, the contact angle of the water droplet was 164.5±1.2°, and the rolling angle was 6±0.5°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com