Method for preparing coal water slurry by matching low-rank coal low-temperature pyrolysis semicoke with non-caking coal

A low-temperature pyrolysis, non-stick coal technology, used in liquid carbonaceous fuels, petroleum industry, fuels, etc., can solve the problem of semi-coke utilization approaching saturation and other problems, and achieve the effects of not easy deposition, simple and reliable methods, and easy availability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

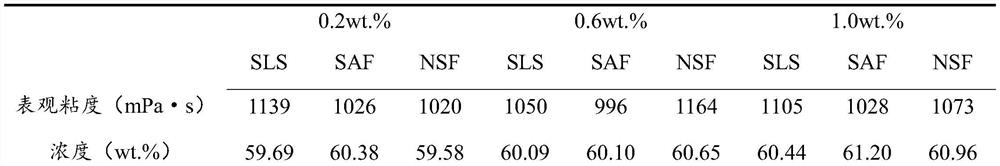

Embodiment 1

[0046] The semi-coke obtained after pyrolysis treatment at 550 ℃ for 30 min was taken in the pyrolysis plant, and the semi-coke obtained was processed by a rapid compaction coal pulverizer for 720 s to obtain semi-coke powder with a maximum particle size of 200 μm. The non-stick coal was naturally air-dried in the air for 24 hours to obtain an air-dried coal sample, and the coal sample was processed by a rapid compaction coal mill for 1080 s to obtain a non-stick coal powder with a maximum particle size of 100 μm. According to the mass ratio of "non-stick coal: semi-coke = 9:1", 0.2%, 0.6wt.% and 1.0wt.% of sodium lignosulfonate (SLS), sulfonated acetone formaldehyde polycondensate ( SAF) and naphthalenesulfonic acid formaldehyde condensate (NSF) dispersant and 30-40wt.% water, use a mechanical stirring paddle to stir for 5min at a rotating speed of 500r / min to prepare a semi-coke-non-stick coal-water slurry. The slurry properties such as slurry concentration, apparent viscosi...

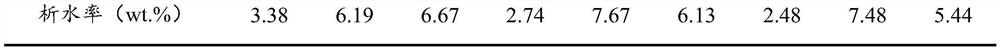

Embodiment 2

[0051] The semi-coke obtained after pyrolysis treatment at 550 ℃ for 30 min was taken from the pyrolysis plant, and the semi-coke was processed by rapid compaction coal milling for 720 s to obtain semi-coke powder with a maximum particle size of 200 μm. The non-stick coal was naturally air-dried in the air for 24 hours to obtain an air-dried coal sample, and the coal sample was processed by a rapid compaction coal mill for 1080 s to obtain a non-stick coal powder with a maximum particle size of 100 μm. According to the mass ratio of "non-stick coal: semi-coke = 8:2", 0.2%, 0.6wt.% and 1.0wt.% of sodium lignosulfonate (SLS), sulfonated acetone formaldehyde polycondensate ( SAF) and naphthalenesulfonic acid formaldehyde condensate (NSF) dispersant and 30-40wt.% water, use a mechanical stirring paddle to stir for 5min at a rotating speed of 500r / min to prepare a semi-coke-non-stick coal-water slurry. The slurry properties such as slurry concentration, apparent viscosity and water...

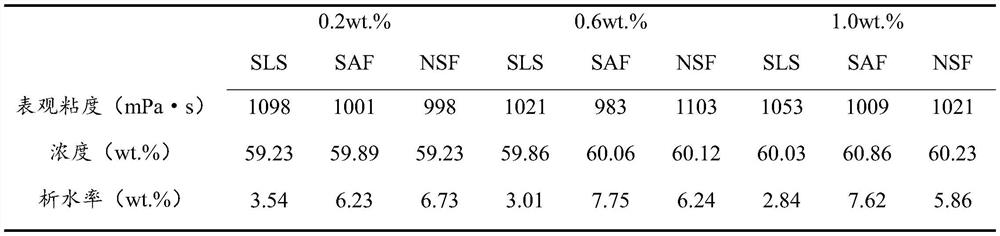

Embodiment 3

[0055] The semi-coke obtained after pyrolysis treatment at 550 ℃ for 30 min was taken from the pyrolysis plant, and the semi-coke was processed by rapid compaction coal milling for 720 s to obtain semi-coke powder with a maximum particle size of 200 μm. The non-stick coal was naturally air-dried in the air for 24 hours to obtain an air-dried coal sample, and the coal sample was processed by a rapid compaction coal mill for 1080 s to obtain a non-stick coal powder with a maximum particle size of 100 μm. According to the mass ratio of "non-stick coal: semi-coke = 7:3", 0.2%, 0.6wt.% and 1.0wt.% of sodium lignosulfonate (SLS), sulfonated acetone formaldehyde polycondensate ( SAF) and naphthalenesulfonic acid formaldehyde condensate (NSF) dispersant and 30-40wt.% water, using a mechanical stirring paddle to stir at a speed of 500r / min for 5min to prepare a semi-coke-non-stick coal-water slurry. The slurry properties such as slurry concentration, apparent viscosity and water separa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com