Electromagnetic shielding packaging body and preparation method thereof

An electromagnetic shielding and encapsulation technology, applied in the field of electromagnetic shielding encapsulation and its preparation, can solve the problems of complex circuit board structure, poor shielding effect, short circuit of shielding film, etc., to ensure electromagnetic shielding effect, improve grounding reliability, prevent The effect of direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

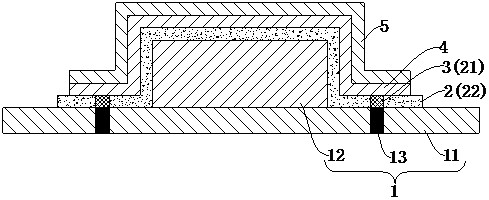

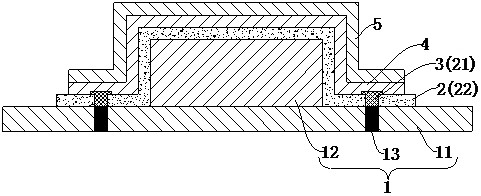

[0086] This embodiment proposes an electromagnetic shielding package and a preparation method thereof. The electromagnetic shielding package includes an integrated circuit board 1 , an insulating film 2 , a shielding film 4 and a protective film 5 , and the upper end of the grounding terminal 13 is exposed on the substrate 11 . Side (structure can refer to appendix figure 2 , 3 shown), and the groove 21 is arranged in a closed ring around the outer periphery of the electronic component 12 , and the conductive portion 3 is a plurality of sections of conductive glue arranged at discontinuous intervals along the extending direction of the groove 21 . Specifically, two electronic components 12 are provided on the substrate 11 , the minimum distance between the two electronic components 12 is 0.5 mm, and the width of the ground terminal 13 is 1.0 mm. The composition of insulating film 2 includes aluminum oxide and epoxy resin, and the thickness is 80 μm; the composition of conduc...

Embodiment 2

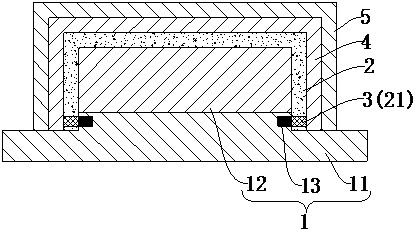

[0089] This embodiment proposes an electromagnetic shielding package and a manufacturing method thereof. The electromagnetic shielding package differs from Embodiment 1 only in that the conductive portion 3 of the electromagnetic shielding package is a continuous annular shape along the extending direction of the groove 21 . Conductive plastic. In the preparation method, a glue dispenser is used to dispense glue in the groove 21 to form the continuous ring-shaped conductive glue, and the conductive glue fills the groove 21. Image 6 shown. The rest are the same as those in Embodiment 1, and are not repeated here.

Embodiment 3

[0091] This embodiment proposes an electromagnetic shielding package and a preparation method thereof. The electromagnetic shielding package differs from Embodiment 2 only in that the minimum distance between the two electronic components 12 of the electromagnetic shielding package is 0.3 mm, and the shielding The thickness of the film 4 includes 50 μm or 100 μm. In the manufacturing method, the groove widths of the grooves 21 formed on the insulating film 2 include three types: 0.2 mm, 0.3 mm and 0.5 mm. The rest are the same as in Embodiment 2, and are not repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com