Functional yarn and preparation method and device thereof

A functional and yarn technology, applied in the field of functional yarn and its preparation, can solve the problems affecting the activity of functional particles, fall off, continuity failure, etc., achieve outstanding functionality and durability, improve bonding strength, and improve service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

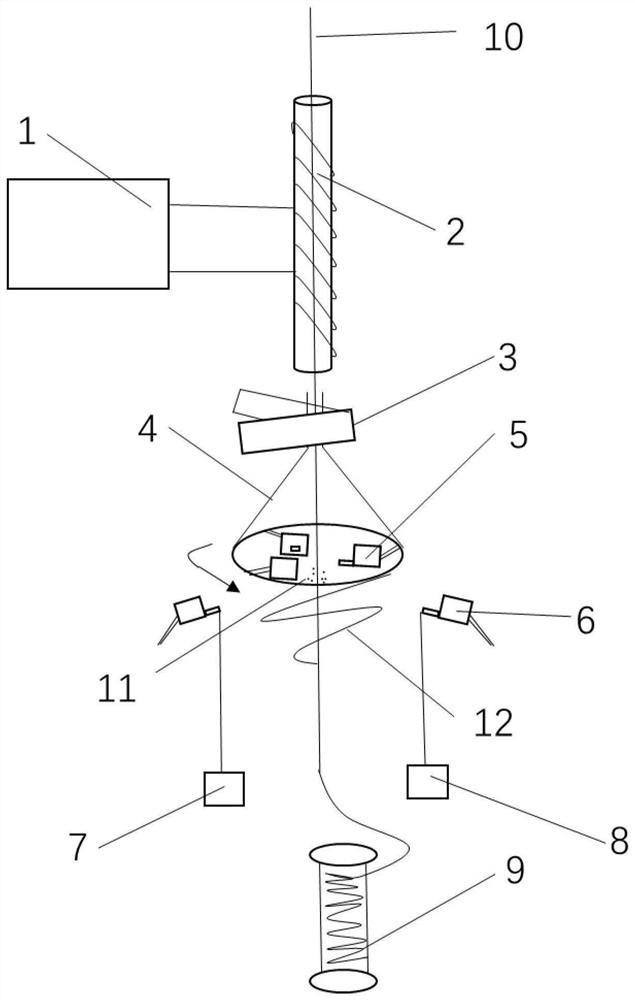

[0042] Example 1 Preparation of anti-arc yarn

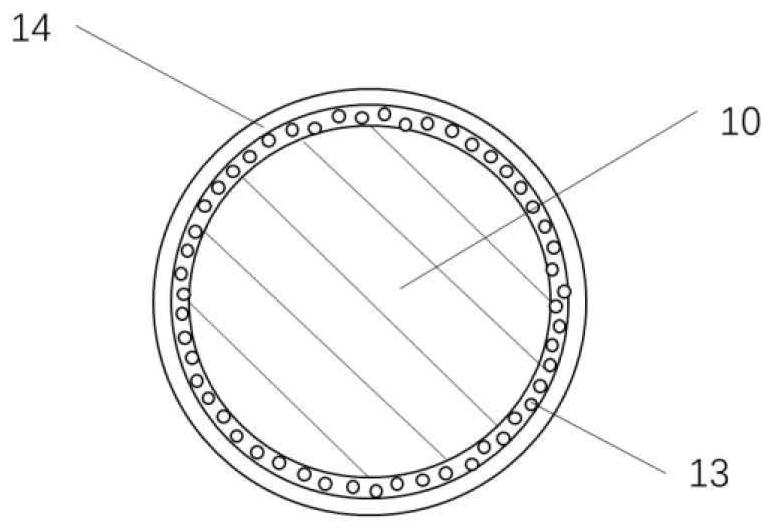

[0043] This embodiment relates to the preparation of an anti-arc yarn, the anti-arc yarn includes a core yarn, an anti-arc functional layer and a nanofiber coating layer, wherein the core yarn is an ultra-fine steel fiber covered with nylon, and the ultra-fine The diameter of the steel fiber is 28 μm, the diameter of the nylon is 52 μm, and the diameter of the core yarn is 105 μm; the functional particles used in the anti-arc functional layer are gray-white spherical tin oxide particles, the purity is 99.9%, the average particle size is 0.5 μm, and the specific surface area is 99.9%. 4.8m 2 / g, the bulk density is 1.76g / cm 3 , the density is 6.95g / cm 3 ; The nanofiber coating layer is a polyimide layer with a thickness of 35 μm; figure 1 The shown device prepares the above-mentioned anti-arc yarn, and the specific preparation process is as follows:

[0044](1) The core yarn 10 is fed from the upper end of the electrified sole...

Embodiment 2

[0047] Example 2 Preparation of Radiation Resistant Yarn

[0048] This embodiment relates to the preparation of a radiation-resistant yarn, the radiation-resistant yarn includes a core yarn, a radiation-resistant functional layer and a nanofiber coating layer, wherein the core yarn is an ultra-fine steel fiber covered with nylon, and the ultra-fine The diameter of the steel fiber is 25 μm, the diameter of nylon is 50 μm, and the diameter of the core yarn is 100 μm; the functional particles used in the anti-arc functional layer are polyetheretherketone (PEEK) particles with an average particle size of 10 μm and a melting point of 162°C; The fiber cladding layer is a polyimide layer with a thickness of 30 μm; figure 1 The shown device prepares the above-mentioned anti-radiation yarn, and the specific preparation process is as follows:

[0049] (1) The core yarn 10 is fed from the upper end of the electrified solenoid 2, heated by the induction heater 1 to obtain a certain high ...

Embodiment 3

[0052] Example 3 Preparation of Yarns for Highly Breathable Clothing

[0053] The present embodiment relates to the preparation of a highly breathable garment yarn, which comprises a core yarn, a functional layer and a nanofiber covering layer, wherein the core yarn is an ultra-fine steel fiber covered with nylon, The diameter of the ultra-fine steel fiber is 20 μm, the diameter of the nylon is 45 μm, and the diameter of the core yarn is 90 μm; the functional particles used in the functional layer are EPDM particles with an average particle size of 10 μm and a melting point of 130 ° C; The nanofiber coating layer is a polyimide layer with a thickness of 25 μm; figure 1 The shown device prepares the above-mentioned high-breathable garment yarn, and the specific preparation process is as follows:

[0054] (1) The core yarn 10 is fed from the upper end of the electrified solenoid 2, heated by the induction heater 1 to obtain a certain high temperature, and the heated core yarn 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com