Integrally-formed compression-resilience-resistant weft-knitted fabric

A woven fabric and elastic weft technology, applied in the field of anti-compression and resilient weft knitted fabrics, can solve the problems of poor resilience, poor softness, low compression recovery rate, etc., and achieve excellent anti-compression resilience and air permeability. And the effect of good drapability and little fiber damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following are specific embodiments of the present invention and accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

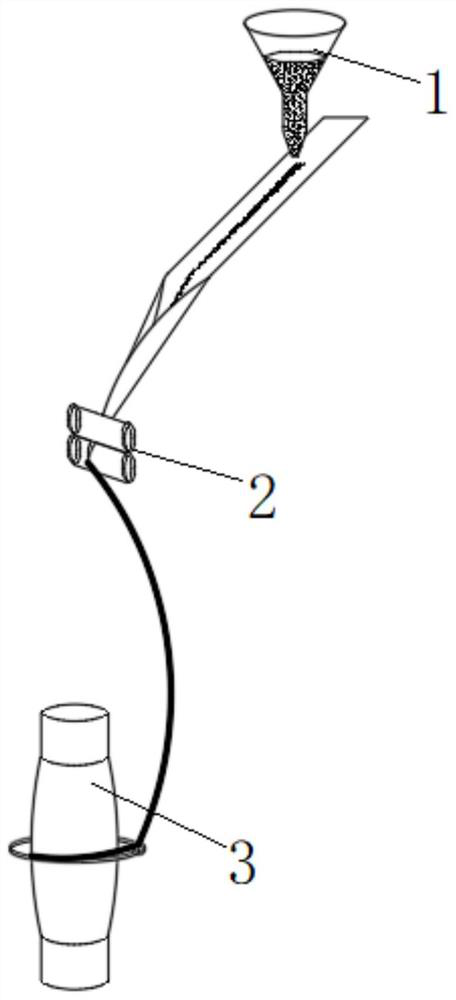

[0022] In a specific embodiment, an integrally formed anti-compression and rebound weft knitted fabric, the fabric is woven from non-woven fabric strips as weft knitting yarns, and the specific step is to first cut the non-woven fabric into non-woven fabric strips , Winding, twisting, doubling and sizing of non-woven fabric strips before weft knitting.

[0023] The knitted fabric woven from non-woven fabric strips as a raw material is integrally formed, has a certain thickness, and has excellent compression resistance and resilience.

[0024] The non-woven fabric is cut into a non-woven fabric strip by a non-woven fabric slitting machine, and the divided non-woven fabric strip is wound on a bobbin through a winder. The width of the non-woven fabric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com