High-elasticity starch cavitary hemostatic material as well as use and preparation method thereof

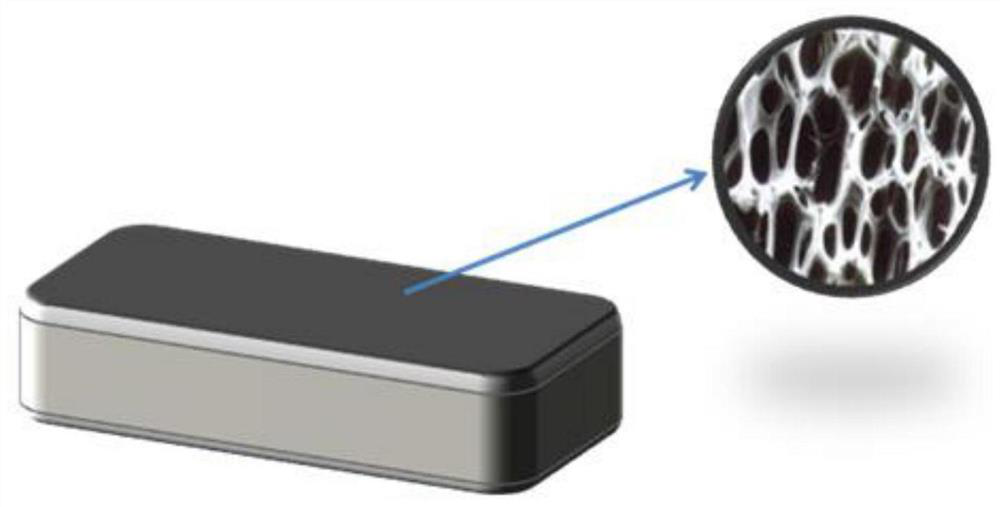

A hemostatic material with high elasticity technology, applied in the field of biomedical materials, can solve the problems of fast degradation, poor water absorption, and inability to support hemostatic effect, etc., and achieve the effect of convenient acid removal, fine surface and uniform voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

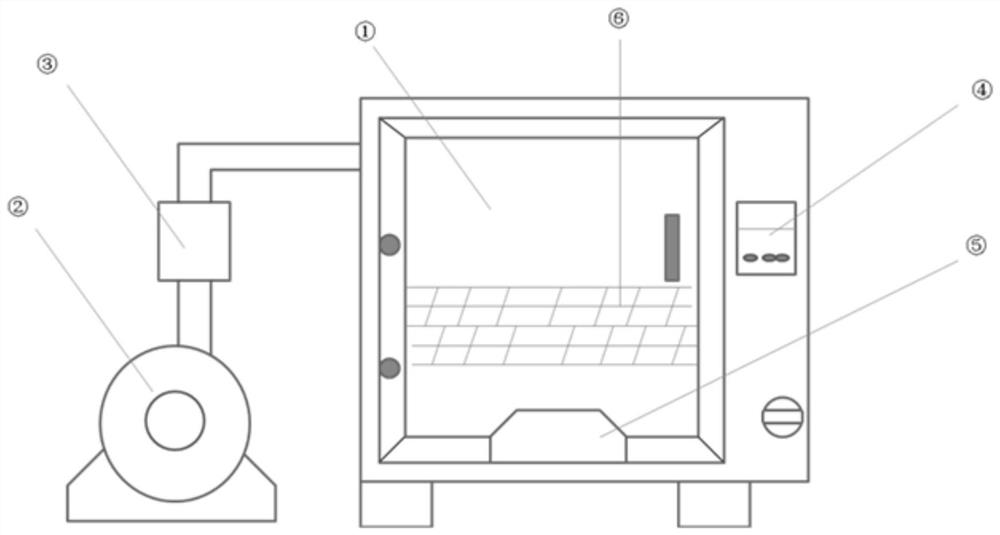

[0042] The present invention further provides a method for preparing the above-mentioned highly elastic starch cavity hemostatic material, comprising the following steps:

[0043] Dissolve the feed liquid and fill it with an appropriate container; use the gradient cooling method to freeze-dry the product, put the freeze-dried sponge into a special container for high-temperature acid vapor cross-linking, and pulverize and sieve the cross-linked sponge. Then, the sponge powder is put into the carboxymethyl cellulose solution, and the product is freeze-dried by means of gradient cooling. The highly elastic starch cavity hemostatic material is obtained by packaging and sterilizing the freeze-dried product.

[0044] In the above-mentioned preparation method, its concrete steps are:

[0045] Step 1, dissolve the feed liquid; add one or more of the starch or its derivatives into the beaker, after swelling for 1-12 hours, heat it to 40-90 ° C, and slowly add other said other polymers...

Embodiment 1

[0068] The present embodiment provides a preparation method of a highly elastic starch cavity hemostatic material, the preparation method comprising the following steps:

[0069] 1. Add 100ml of purified water to the beaker, add 2g of sodium starch glycolate, swell for 2 hours, heat to 80°C, slowly add 3g of carboxymethyl chitosan under stirring, and continue stirring for 4 hours to fully dissolve the solution.

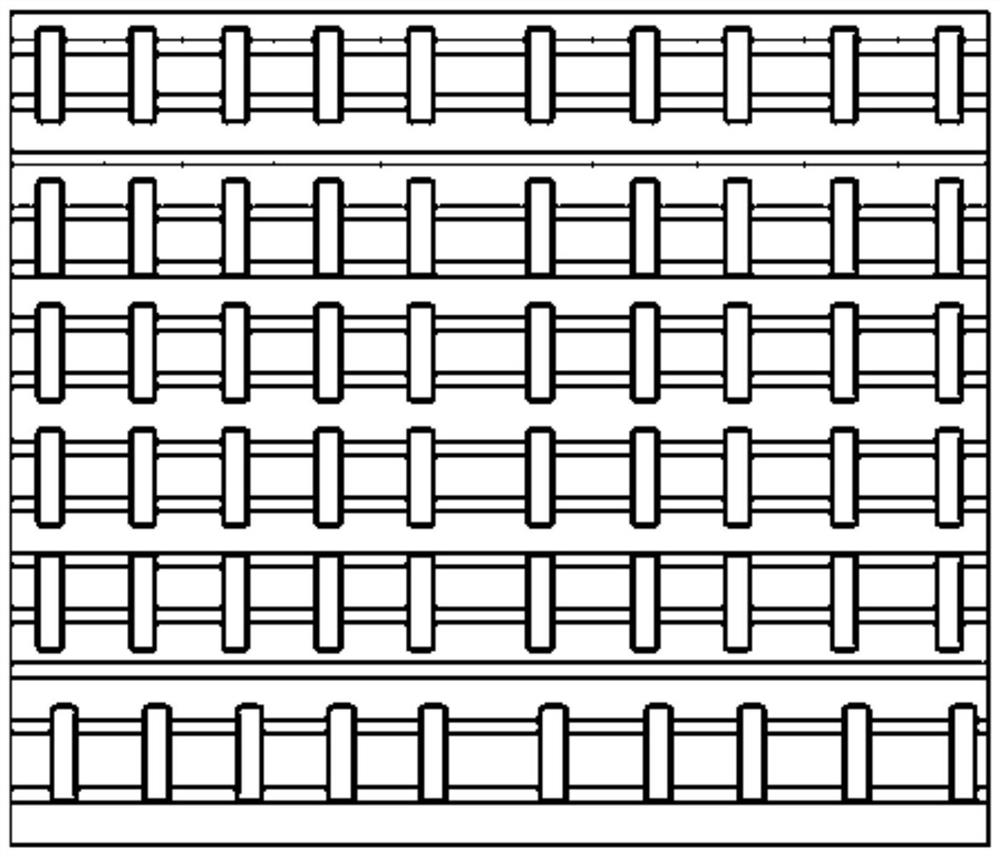

[0070] 2. After the solution described in step 1 is dissolved, pour it into freeze-drying containers according to different specifications, put the mold into the freezer, according to a, the temperature of the freezer is 1 ℃, and the time is 8h; b, the temperature of the freezer is -3℃, time is 15h; c, freezer temperature is -7℃, time is 8h; d, freezer temperature is -10℃, time is 20h; e, freeze dryer temperature is -55℃, time is 3h; f , the temperature of the lyophilizer partition is -15℃, and the time is 10h; g, the temperature of the lyophilizer partition is 0℃, an...

Embodiment 2

[0077] The present embodiment provides a preparation method of a highly elastic starch cavity hemostatic material, the preparation method comprising the following steps:

[0078] 1. Add 100ml of purified water and 3g of dextrin to the beaker. After swelling for 2 hours, heat to 50°C. Slowly add 4g of sodium carboxymethylcellulose under stirring, and continue stirring for 5 hours to fully dissolve the solution.

[0079] 2. After the solution described in step 1 is dissolved, pour it into freeze-drying containers according to different specifications, put the mold into the freezer, according to a, the temperature of the freezer is 1 ℃, and the time is 3h; b, the temperature of the freezer is -3℃, time is 6h; c, freezer temperature is -7℃, time is 9h; d, freezer temperature is -10℃, time is 20h; e, freeze dryer temperature is -55℃, time is 3h; f , the temperature of the lyophilizer partition is -15℃, and the time is 10h; g, the temperature of the lyophilizer partition is 0℃, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com