Method and device for rapidly preparing silver nanowires

A nano-silver wire and fast technology, applied in the direction of nanotechnology, can solve the problems of waste, excessive and insufficient demand for ethylene glycol solution, etc., and achieve the effects of rapid preparation, easy heating, and faster speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

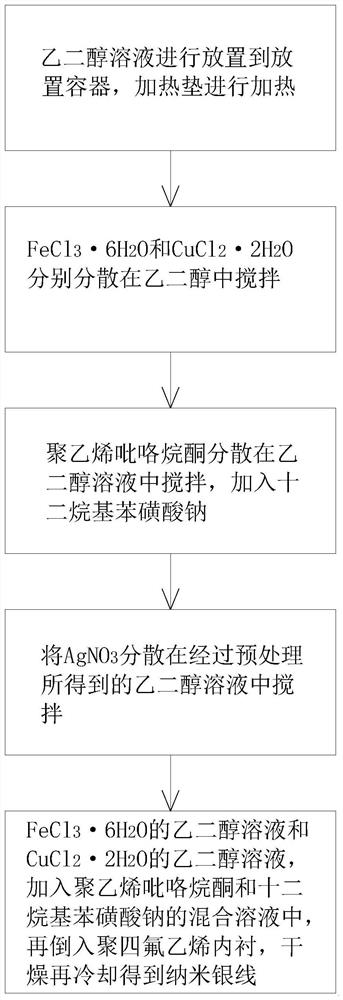

[0046] like figure 1 As shown, the present invention is a method for rapidly preparing nano-silver wires, comprising the following steps:

[0047] Step 1, the ethylene glycol solution is placed in the placing container 5, and then the heating pad 3 at the lower end is heated to remove the moisture in the ethylene glycol solution;

[0048] Step 2, FeCl 3 ·6H 2 O and CuCl 2 ·2H 2 O is dispersed in the ethylene glycol obtained through step 1 pretreatment respectively and stirred;

[0049] Step 3, the polyvinylpyrrolidone is dispersed in the ethylene glycol solution and stirred, and sodium dodecylbenzenesulfonate is added;

[0050] Step 4, AgNO 3 Disperse and stir in the ethylene glycol solution obtained by the pretreatment in step 1;

[0051] Step 5, the FeCl gained in step 2 3 ·6H 2 Glycol solution of O and CuCl 2 ·2H 2 The ethylene glycol solution of O is added to the mixed solution of polyvinylpyrrolidone and sodium dodecylbenzenesulfonate obtained in step 3, then p...

Embodiment 2

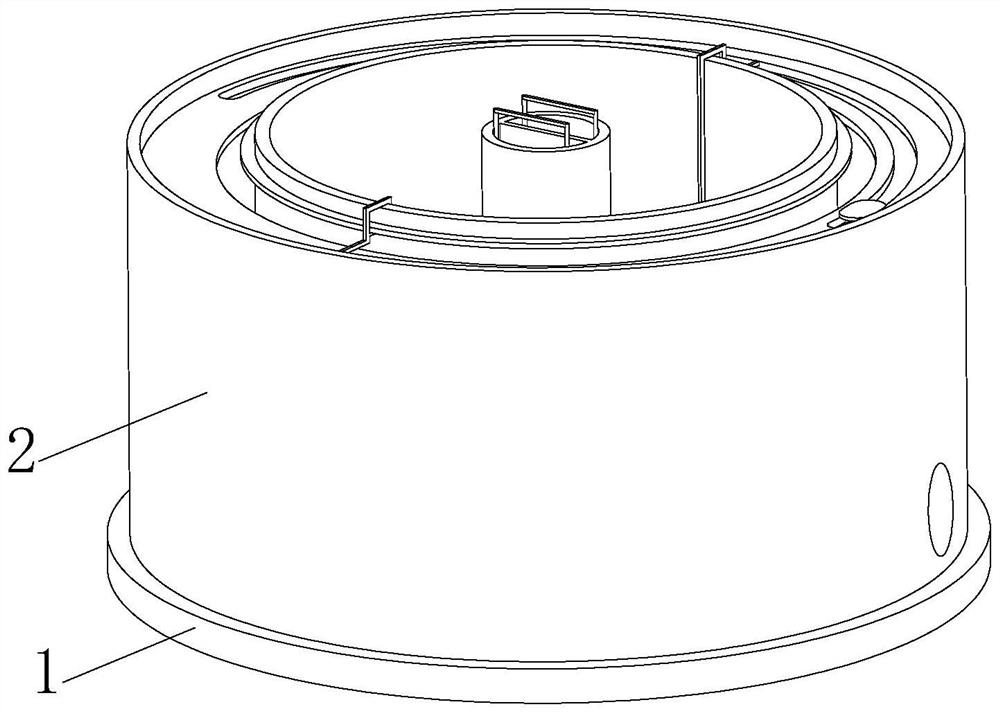

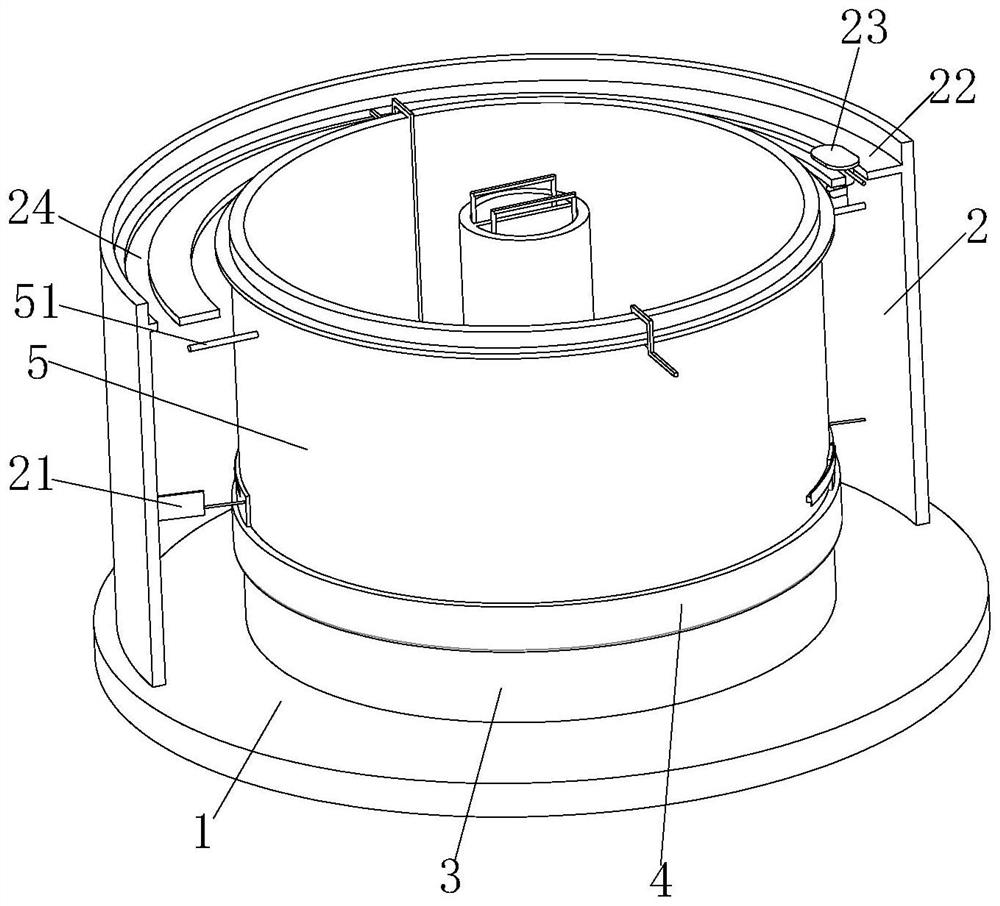

[0053] like Figure 2-7 As shown, a device for rapidly preparing nano-silver wires includes a base 1, an upper end of the base 1 is fixedly mounted with a jacket 2, and a container 5 is arranged inside the jacket 2;

[0054] A heating pad 3 is fixedly installed on the upper end of the base 1, a limit ring 4 is fixedly installed on the upper end of the heating pad 3, and the container 5 is placed in the limit ring 4;

[0055] A limiting plate 22 is welded on the inner wall of the outer casing 2 , and a sliding frame 23 is arranged on the limiting plate 22 .

[0056] The limit plate 22 is provided with an arc-shaped chute 24, the sliding frame 23 is slidably clamped in the arc-shaped chute 24, one end of the arc-shaped chute 24 is close to the axis of the outer casing 2, and the other end of the arc-shaped chute 24 is gradually away from the axis of the jacket 2;

[0057] The sliding frame 23 includes a moving slider 231, an elastic pulling rope 232, a lower rod 233 and a matc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com