Super low-temperature-resistant fluorine film and preparation method thereof

A low temperature resistant and fluorine film technology, applied in the field of ultra-low temperature resistant fluorine film and its preparation, can solve the problems of cracking or delamination of the outer film, affecting the stability of the coated board, increasing labor costs, etc., to avoid sticking. The effect of knot force reduction, good low temperature adaptability and stability, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

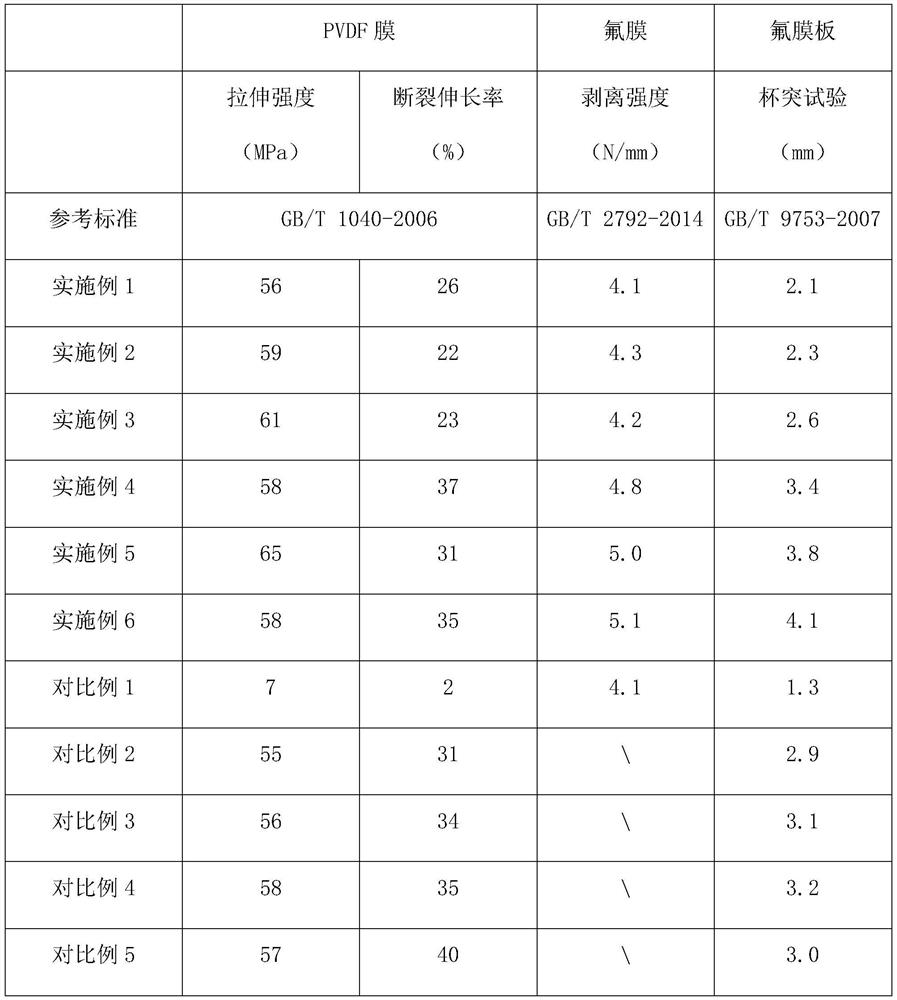

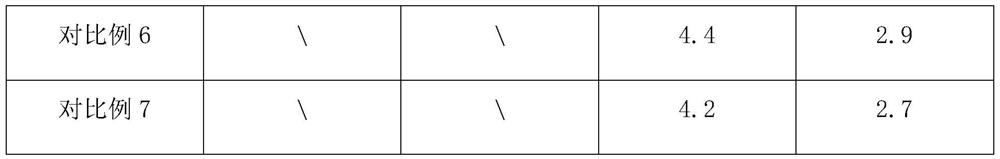

Examples

Embodiment 1

[0035] (1) get PET film, carry out double-sided corona treatment, the corona value is 46dyne;

[0036] (2) Coat the inner surface of the PET film with polyurethane resin at a coating speed of 50mm / s to form an adhesive layer; composite with PVDF film, the composite process is: drying tunnel temperature 100°C, wind speed 6m / s;

[0037] (3) Coating polyurethane resin on the outer surface of the PET film, the coating speed is 50mm / s, forming a glue layer, and carrying out corona treatment, the corona value is 46dyne; composite with metal plate, the composite process is: drying tunnel temperature 100 ℃ , the wind speed is 6m / s, and the fluorine membrane plate is obtained.

[0038] Wherein, the PVDF film includes the following weight components: 60 parts of PVDF, 5 parts of titanium dioxide, 5 parts of toughening agent 2390, 1 part of lubricant C28, 0.1 part of antioxidant 1010, and 0.5 part of ultraviolet absorber 234;

[0039]The preparation process of PVDF film is as follows: b...

Embodiment 2

[0042] (1) get PET film, carry out double-sided corona treatment, the corona value is 47dyne;

[0043] (2) Coat the inner surface of the PET film with polyurethane resin at a coating speed of 75mm / s to form an adhesive layer; compound with the PVDF film, the compounding process is: the drying tunnel temperature is 130°C, and the wind speed is 10m / s;

[0044] (3) Coating polyurethane resin on the outer surface of the PET film, the coating speed is 75mm / s, forming a glue layer, and carrying out corona treatment, the corona value is 47dyne; it is compounded with a metal plate, and the compounding process is: drying tunnel temperature 130 ℃ , the wind speed is 10m / s, and the fluorine membrane plate is obtained.

[0045] Among them, the PVDF film includes the following weight components: 77.5 parts of PVDF, 13 parts of titanium dioxide, 7 parts of toughening agent 2390, 1.5 parts of lubricant C28, 0.2 parts of antioxidant 1010, and 0.8 parts of ultraviolet absorber 234;

[0046] T...

Embodiment 3

[0049] (1) get PET film, carry out double-sided corona treatment, the corona value is 48dyne;

[0050] (2) Coat the inner surface of the PET film with polyurethane resin at a coating speed of 80mm / s to form an adhesive layer; compound with the PVDF film, the compounding process is: the drying tunnel temperature is 160°C, and the wind speed is 15m / s;

[0051] (3) Coating polyurethane resin on the outer surface of the PET film, the coating speed is 80mm / s, forming a glue layer, and carrying out corona treatment, the corona value is 48dyne; composite with metal plate, the composite process is: drying tunnel temperature 160 ℃ , the wind speed is 15m / s, and the fluorine membrane plate is obtained.

[0052] Among them, the PVDF film includes the following weight components: 80 parts of PVDF, 20 parts of titanium dioxide, 10 parts of toughening agent 2390, 5 parts of lubricant C28, 0.5 part of antioxidant 1010, and 1 part of ultraviolet absorber 234;

[0053] The preparation process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com