Solvent-free lignin fluorescent material and preparation method thereof

A technology of fluorescent material and lignin, applied in the field of solvent-free lignin fluorescent material and its preparation, can solve the problems of fluorescence quenching, nanomaterial agglomeration, easy to be affected by temperature, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 3 mL of sodium lignosulfonate aqueous solution containing 105 mg to 8 mL of 50 mM N,N,N-trimethyl-8-(4-(2-(4-octyloxyphenyl)-1, bromide) solution. 2-diphenylvinyl)phenoxy)butane-1-ammonium aqueous solution was mixed, the reaction system was magnetically stirred at room temperature for 10 minutes and then left to stand for treatment. After the precipitation was complete, the supernatant was discarded, and the obtained precipitation was The solvent-free lignin fluorescent material of the present invention is prepared after successively washing with water, filtering out water, and freeze-drying for 24 hours.

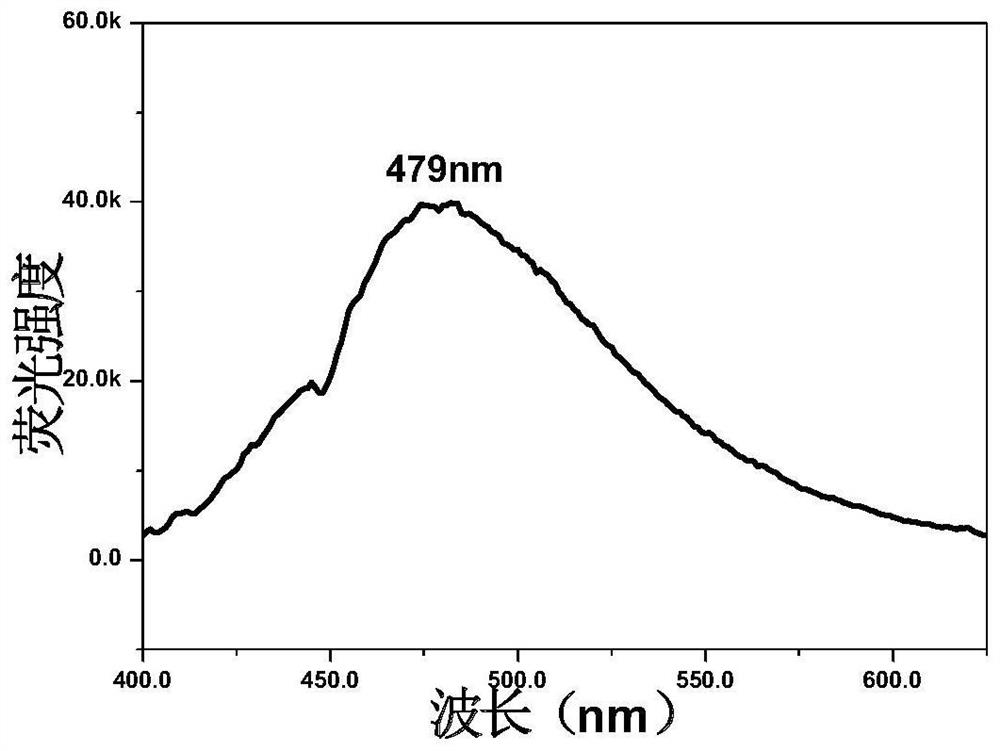

[0025] The prepared solvent-free lignin fluorescent material, the fluorescence emission spectrum under the excitation of 365nm wavelength, such as figure 1 As shown, it is concluded that the solvent-free lignin fluorescent material of the present invention has a fluorescence emission peak at 400-600 nm under excitation at a wavelength of 365 nm, and a maximum emi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com