Preparation method of polymer carbon dots, polymer carbon dot film as well as preparation method and application of polymer carbon dot film

A polymer and polymerization reaction technology, applied in chemical instruments and methods, nano-carbon, nanotechnology for materials and surface science, etc., can solve poor optical performance, low heat extraction efficiency, and application limitations of light-emitting diodes and other issues, to achieve the effect of enhancing light extraction efficiency, improving luminous efficiency, and enhancing optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

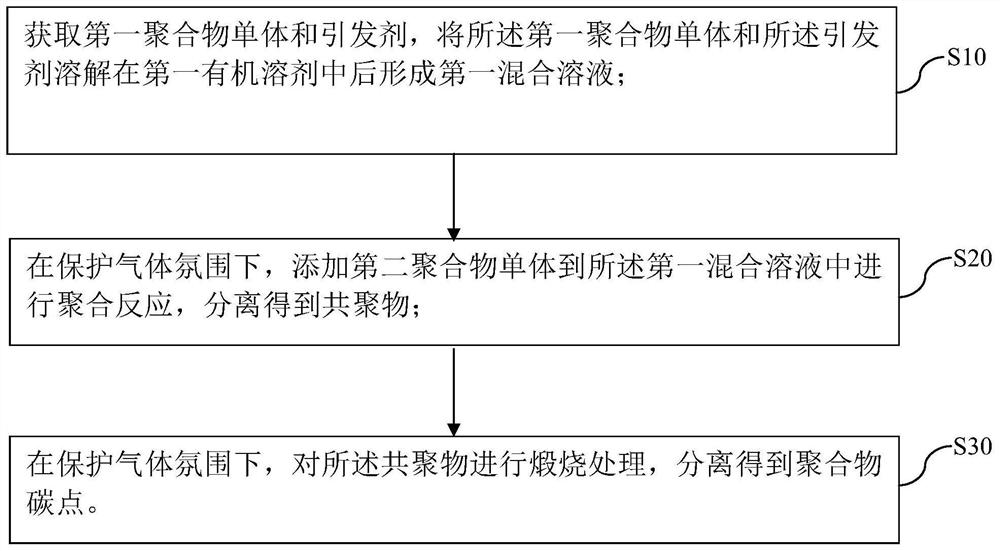

[0028] Append figure 2 As shown, the embodiment of the present invention provides a method of preparing a polymer carbon dot, comprising the steps of:

[0029] S10. Get the first polymer monomer and the initiator, dissolve the first polymer monomer and the initiator after the first organic solvent is formed, and the first mixed solution is formed;

[0030] S20. In protective gas atmosphere, the second polymer monomer is added to the first mixed solution to perform polymerization, and the copolymer is separated;

[0031] S30. Under the protective gas atmosphere, the copolymer is calcined, and the polymer carbon dot is separated.

[0032] It should be noted that in the step of separating the copolymer, the drying treatment can be performed after separation to facilitate the subsequent calcination process.

[0033] In some embodiments, the polarity of the first polymer monomer is lower than the polarity of the second polymer monomer. Among them, the second polymer monomer can select ...

Embodiment 1

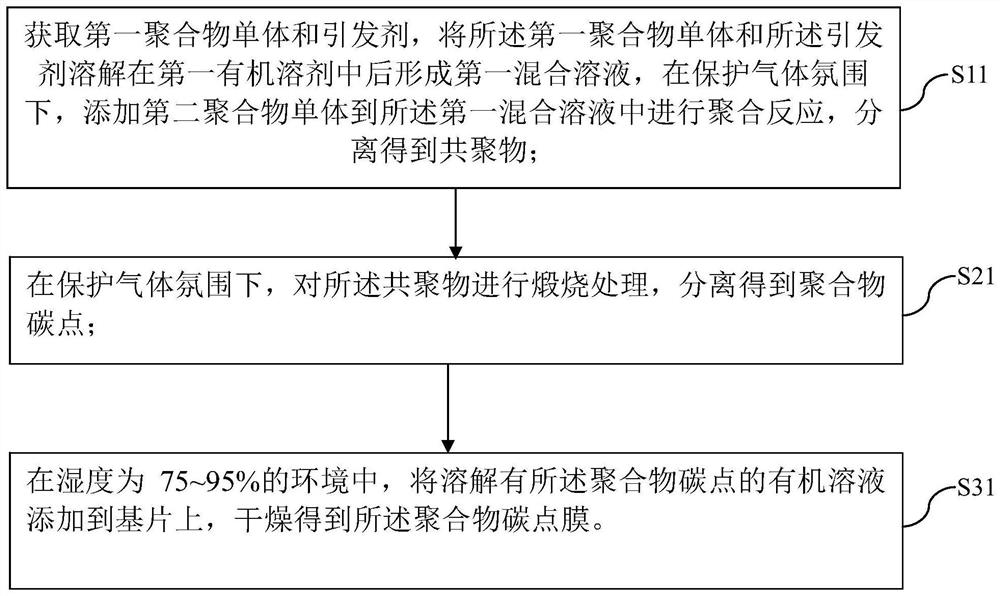

[0089] A polymer carbon dot film comprising the following preparation steps:

[0090] 1 Under nitrogen protection, 900 ml of toluene, 48 mmol of triethyl aluminum and 40 mmol allyl alcohol were added to the flask, and the mixture was stirred to 50 ° C for 10 min, then 1 ml of toluene solution containing 1.57 mmol metal metallogenic complex was added and 2 l / h. The flow is introduced into ethylene, and the reaction is continuously reacted at 50 ° C, and finally, 20 ml of isobutanol is added to stop the polymerization, and the polymer mixture is poured into an acidic methanol, and the endoxylated polyethylene is obtained.

[0091] 2 Take 0.05 g of ammonium sulfate, 25 ml of DMF and step 1, the endoxy polyethylene obtained is mixed into the flask; then, under a nitrogen atmosphere, a mixed solution of a vinylpyrrolidone and 6 mL DMF is dropped by dropping, and at 70 The reaction was reacted at ° C for 5 h, and finally washed to dry the poly (ethylene-vinylpyrrolidone);

[0092] 3 3...

Embodiment 2

[0095] A polymer carbon dot film comprising the following preparation steps:

[0096] 1 Add 10 g of methacrylate, 0.1 g of azo diisobutyronitrile and 30 ml dimethyl sulfoxide to stir well; then, under a nitrogen atmosphere, drop diamethylene chloride Precation and 10 ml of dimethyl sulfoxide mixed solution, and react at 75 ° C for 3 h, and finally washed to dry the poly (methyl methacrylate-dimethyldienne ammonium chloride);

[0097] 2 Grinding 4 g of the above-described dry poly (methyl methacrylate-dimethyl diene ammonium chloride) to the powder, placed in a quartz boat; then under a nitrogen atmosphere, the temperature rise rate of 5 ° C / min rises to 200 At ° C, the reaction was 3 h, and the resulting product was washed with deionized water and chloroform, and the polymer carbon dot was separated.

[0098] 3 Disperse the polymer carbon dot in chloroform into a concentration of 30 mg / ml to obtain a polymer carbon dichloromethane solution; a polymer carbon dot composite a sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com