Static rotational flow well washing device and method for washing in-situ leaching drill hole

A static and in-situ immersion technology, used in earth-moving drilling, wellbore/well components, and process efficiency improvement. It can solve problems such as low mud and sand washing efficiency, achieve a clear design concept, improve fluid dynamic pressure, and increase self-weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

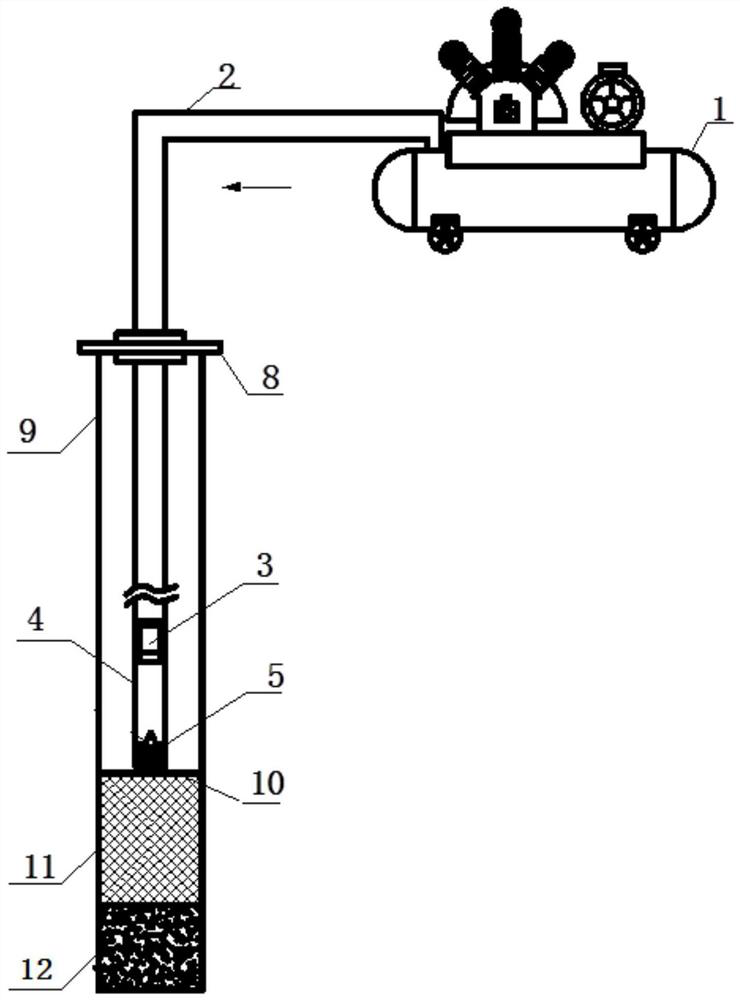

[0055] Uranium leaching well in a certain area of Erlian Basin, Inner Mongolia

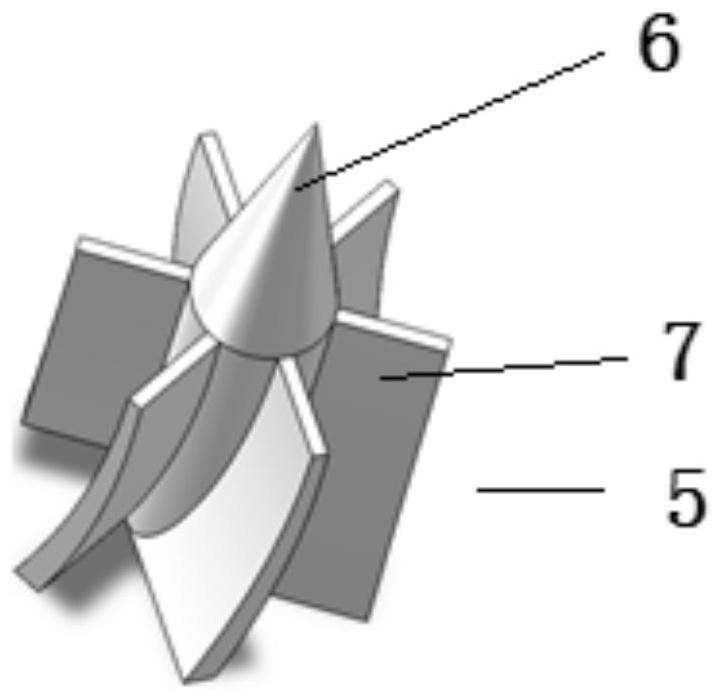

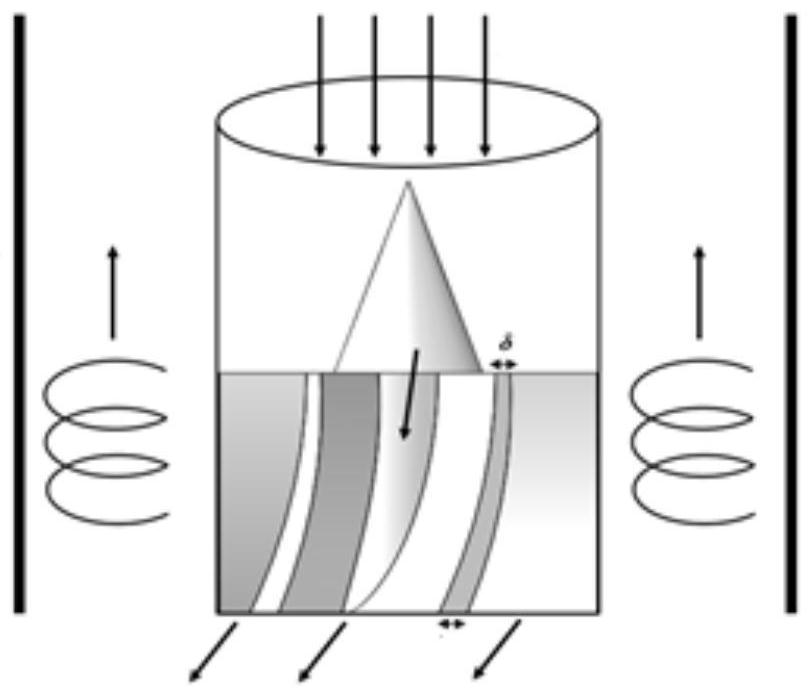

[0056] The depth of the uranium mine is more than 300m, the inner diameter of the pumping hole casing is DN 128mm; the design pressure of the fan is 5Mpa, the actual work is about 3.5MPa, the inner diameter of the air conveying pipe is DN 25mm, and the length of the steel pipe is 1m; The diameter of the circle is 9mm; the number of swirl blades is 6, that is, the rotation angle of the blade is 60° (360° / 6=60°), the helix angle is set to 60°, the vertical height is 25mm, and the width is 7mm. The diameter of the cylinder is 9mm, which is convenient for the welding of the blade and the inner wall of the gas delivery pipe, the thickness of the top of the blade is 1mm, and the thickness of the bottom is 2mm, such as image 3 shown.

[0057] According to the results of measuring the height of the sand in the sand tube, two wells with similar heights of sand are selected, with a height of about 6m. ...

Embodiment 2

[0059] A uranium leaching well in a certain place in the Yili Basin, Xinjiang, is an in-situ leaching uranium well that has been in operation for many years. During normal production, the pumping volume is generally greater than 4m 3 / h, when the pumping volume drops to 2m 3 When the / h is below, it is considered that the downhole blockage is serious, and the purpose of well flushing is to increase the pumping volume.

[0060] The depth of the uranium mine is more than 350m, the inner diameter of the pumping hole casing is DN 128mm; the design pressure of the fan is 5MPa, the actual working is about 3.5MPa, the inner diameter of the air conveying pipe is DN 25mm, and the length of the steel pipe is 1m; The diameter of the circle is 9mm; the number of swirl blades is 8, that is, the blade rotation angle is 45° (360° / 8=45°), the helix angle is set to 50°, the vertical height is 25mm, and the width is 7mm. The diameter of the cylinder is 9mm, which is convenient for the welding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com