Preparation method of graphene electron microscope grid

A technology of graphene and graphene membrane, which is applied in the field of structural biology to achieve the effects of easy acquisition, avoiding structural influence, and high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

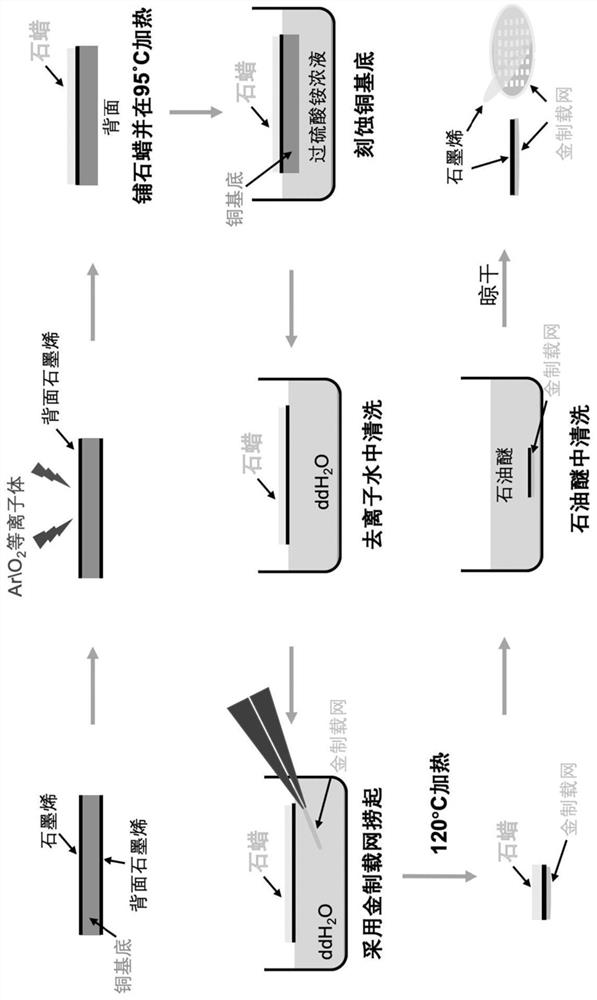

[0079] The present embodiment uses paraffin as the transfer medium to make the graphene electron microscope carrier network, which specifically includes the following steps:

[0080] 1. Removal of graphene on the back: Cut the copper foil covered with graphene grown by chemical vapor deposition (CVD) of suitable size, put the back side up into the Gatan plasma cleaner, and feed oxygen (flow rate 11.5sccm) and argon at the same time (flow rate 35sccm) plasma cleaning was performed for 30 seconds to remove the graphene covered on the backside of the copper foil.

[0081] 2. Waxing: Place the graphene-copper foil structure flat on the cover glass with the front side up, then place the cover glass on a metal bath at 95°C, and take an appropriate amount of paraffin on the graphene surface. The paraffin melts and spreads quickly, covering the graphene surface. Remove the coverslip and leave it at room temperature, the paraffin solidifies rapidly.

[0082] 3. Etch the copper foil: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com