Preparation method of sulfur dioxide and hydrogen sulfide gas adsorbent

A gas adsorbent, sulfur dioxide technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of being easily affected by the environment, easy desorption adsorption capacity, complex preparation process, etc. And the effect, the effect of improving the preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

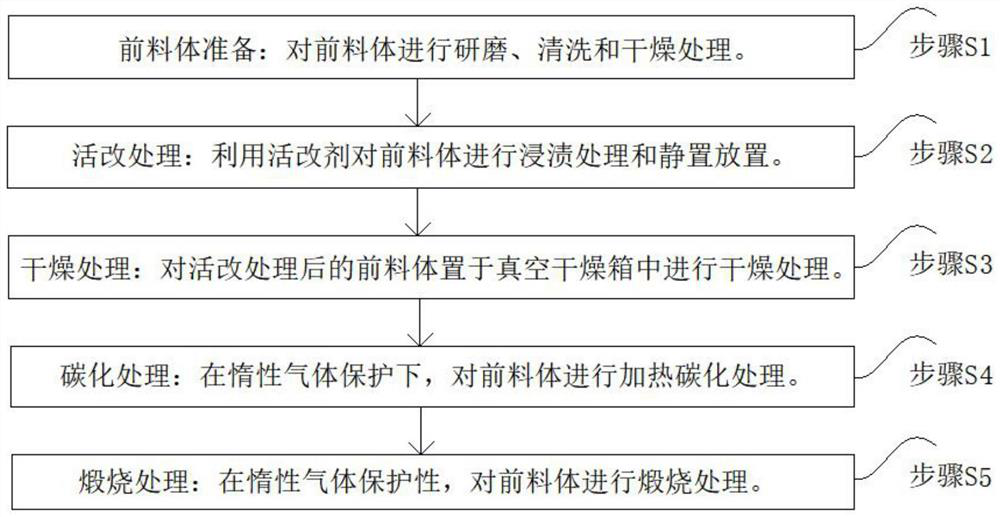

[0027] combine figure 1 As shown, the present invention discloses a preparation method of sulfur dioxide and hydrogen sulfide gas adsorbent, which specifically includes the following steps:

[0028] Step S1, the precursor body is prepared. The precursors, such as coconut shells, are ground, washed and dried to obtain clean precursors.

[0029] Preferably, the particle size of the precursor body after grinding treatment is controlled to be 20-50 mesh to ensure that the final obtained adsorbent has a suitable void size and achieves efficient adsorption of sulfur dioxide and hydrogen sulfide gas. At the same time, the ground and cleaned precursor is dried at 60 to 80° C. for 2 to 3 hours to achieve effective drying of the precursor.

[0030] Of course, precursors of other materials can also be selected, such as fruit shells, walnut shells, apricot pits and wood chips, or even mixed precursors including the above materials can be selected. At this time, according to the structu...

Embodiment 1

[0040] Coconut shells were used as the precursor. First, 10 g of coconut shells were ground and screened to 20-50 mesh, washed with deionized water, and dried at 80°C for 2 hours. Next, the washed precursor was added to 100 g of a 15 wt % cupric chloride solution, immersed for 12 hours, filtered and left to stand for 3 hours. Then, the coconut shells were put into a vacuum drying oven and dried at 80 °C for 2 h. Then, under the protection of nitrogen, the activated coconut shells were heated to 800°C for carbonization treatment for 3h. Finally, under the protection of nitrogen, the target adsorbent was prepared by calcination at 400 °C for 2 h.

Embodiment 2

[0042] Coconut shells were used as the precursor. First, 10 g of coconut shells were ground and screened to 20-50 meshes, washed with deionized water, and dried at 80°C for 2 hours. Next, the washed precursor was added to a mixed solution of 100 g of 10 wt % copper chloride and 5 wt % zinc chloride, immersed for 12 hours, filtered and left to stand for 3 hours. Then, the coconut shells were put into a vacuum drying oven and dried at 80 °C for 2 h. Then, under the protection of nitrogen, the activated coconut shells were heated to 800°C for carbonization treatment for 3h. Finally, under the protection of nitrogen, the target adsorbent was prepared by calcination at 400 °C for 2 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com