Polyamide color master batch resistant to high-temperature carbon black coloring and preparation method of polyamide color master batch

A technology of high temperature resistance and polyamide, which is applied in the field of high temperature resistant carbon black colored polyamide color masterbatch and its preparation, can solve the problems of poor dyeing uniformity, poor compatibility, and difficulty in achieving effective dispersion of particles, and achieve a similar Capacitance improvement, improved stability and coloring effect, good thermal stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The present embodiment is a polyamide color masterbatch colored by high temperature resistant carbon black, and the polyamide color masterbatch colored by high temperature resistant carbon black is prepared by the following steps:

[0044] 60 parts of carbon black, 100 parts of polyamide resin, 8 parts of dispersant, 2 parts of silane coupling agent, 1 part of compatibilizer, 1 part of antioxidant;

[0045] S81: Mix carbon black, silane coupling agent, dispersant, compatibilizer and antioxidant, and ultrasonically disperse for 20 minutes;

[0046] S82: add polyamide resin, stir evenly, transfer to an internal mixer for mixing for 20 min, and then extrude and granulate through a twin-screw extruder to obtain the polyamide masterbatch colored with high temperature resistant carbon black;

[0047] The dispersant is prepared by the following steps:

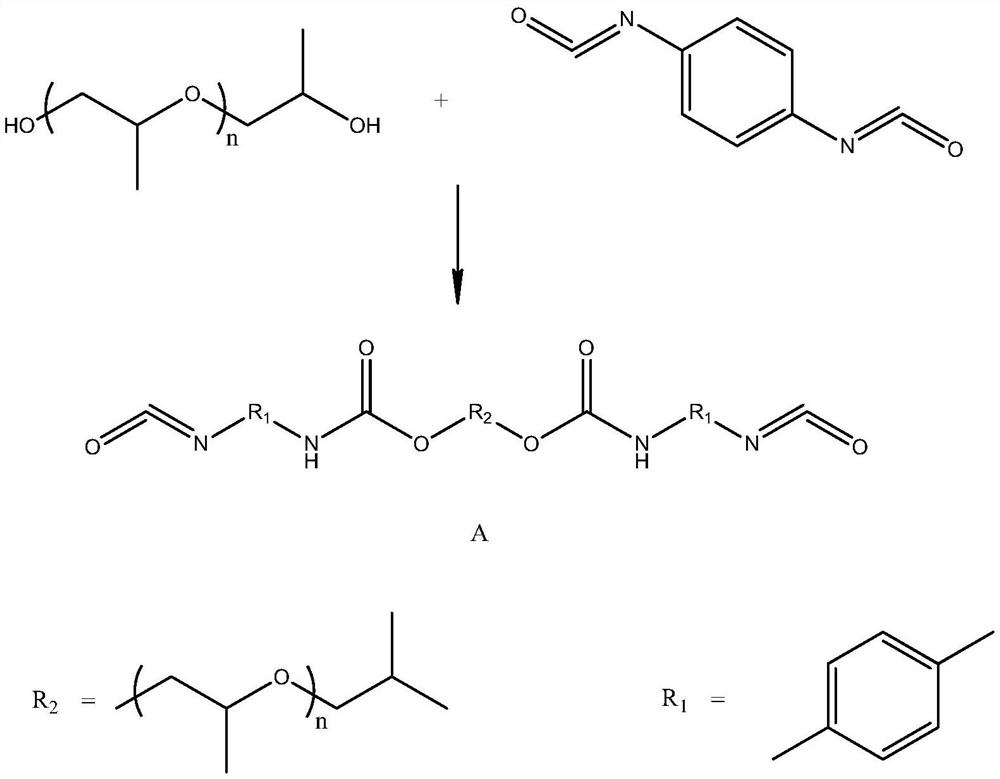

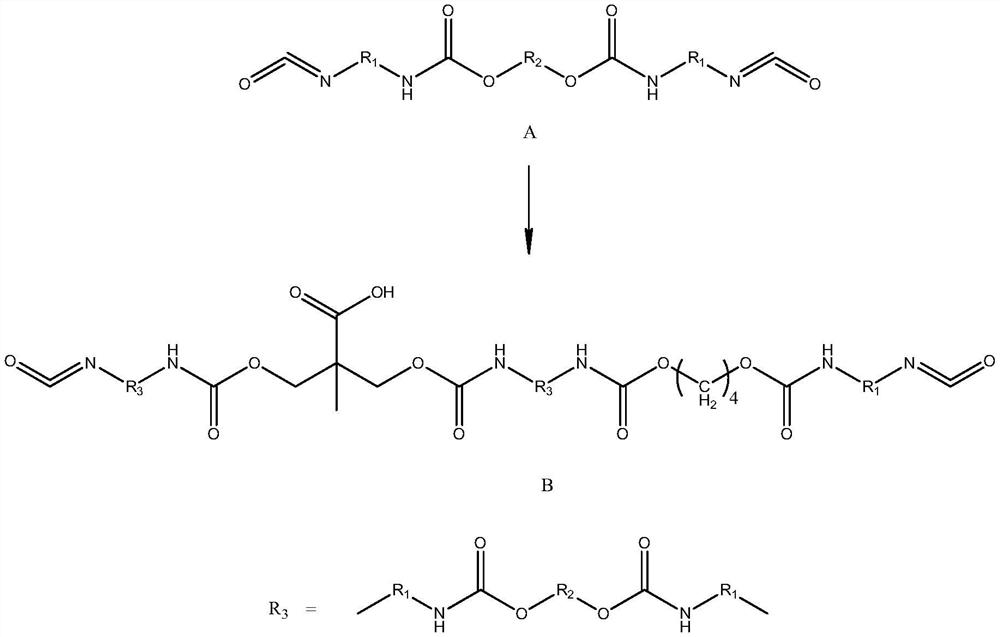

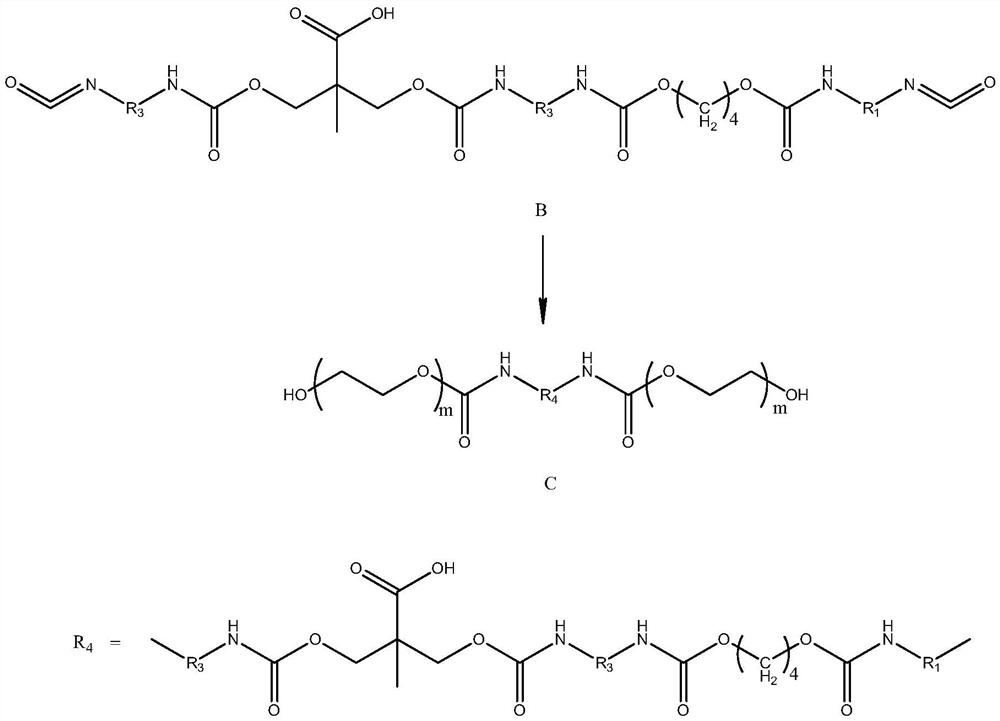

[0048] S21: Place the weighed 21.6g polyoxypropylene glycol in a three-necked flask, add a thermometer, a condenser and a st...

Embodiment 2

[0056] The present embodiment is a polyamide color masterbatch colored by high temperature resistant carbon black, and the polyamide color masterbatch colored by high temperature resistant carbon black is prepared by the following steps:

[0057] 60 parts of carbon black, 100 parts of polyamide resin, 8 parts of dispersant, 5 parts of silane coupling agent, 5 parts of compatibilizer, 5 parts of antioxidant;

[0058] S81: Mix carbon black, silane coupling agent, dispersant, compatibilizer and antioxidant, and ultrasonically disperse for 20 minutes;

[0059] S82: add polyamide resin, stir evenly, transfer to an internal mixer for mixing for 20 min, and then extrude and granulate through a twin-screw extruder to obtain the polyamide masterbatch colored with high temperature resistant carbon black;

[0060] The dispersant is prepared by the following steps:

[0061] S21: Place the weighed 21.6g polyoxypropylene glycol in a three-necked flask, add a thermometer, a condenser and a ...

Embodiment 3

[0069] The present embodiment is a polyamide color masterbatch colored by high temperature resistant carbon black, and the polyamide color masterbatch colored by high temperature resistant carbon black is prepared by the following steps:

[0070] 60 parts of carbon black, 120 parts of polyamide resin, 10 parts of dispersant, 5 parts of silane coupling agent, 5 parts of compatibilizer, 5 parts of antioxidant;

[0071] S81: Mix carbon black, silane coupling agent, dispersant, compatibilizer and antioxidant, and ultrasonically disperse for 30 minutes;

[0072] S82: add polyamide resin, stir evenly, transfer to an internal mixer for mixing for 30 min, and then extrude and granulate through a twin-screw extruder to obtain the polyamide masterbatch colored with high temperature resistant carbon black;

[0073] The dispersant is prepared by the following steps:

[0074] S21: Place the weighed 21.6g polyoxypropylene glycol in a three-necked flask, add a thermometer, a condenser and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com