Lead frame coarsening process

A lead frame and roughening technology, applied in the field of lead frame roughening process, can solve the problems of high cost, low yield, poor stability of lead frame roughening process, etc., achieve high yield, eliminate material differences, and ensure consistency Effects of Sex and Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

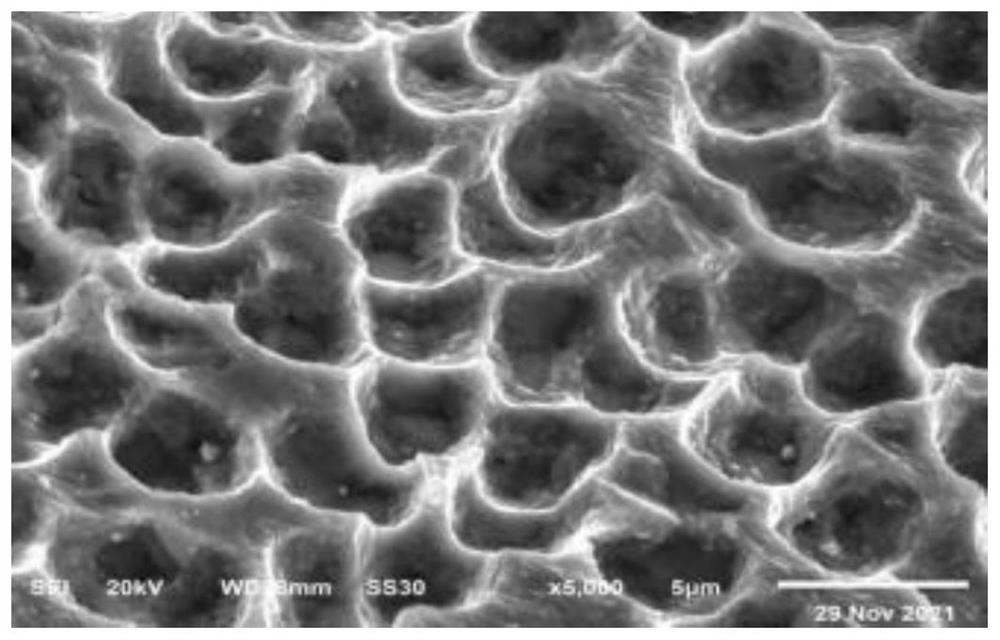

[0047] Pretreatment: Clean the S0P094-16L lead frame: The S0P094-16L lead frame is subjected to the electrolytic degreasing process and the water washing I process by means of bipolar degreasing, and then the S0P094-16L lead frame is cleaned with 10% sulfuric acid. Washing II process. Then, the SOP094-16L lead frame was used as the cathode and the oxygen-free copper column was used as the anode, and electroplating was carried out in the electroplating liquid, and the current density was controlled to 3ASD to obtain a lead frame with a copper plating thickness of 4 μm, and then a copper plating thickness of 4 μm. The lead frame to be roughened is obtained after cleaning with pure water.

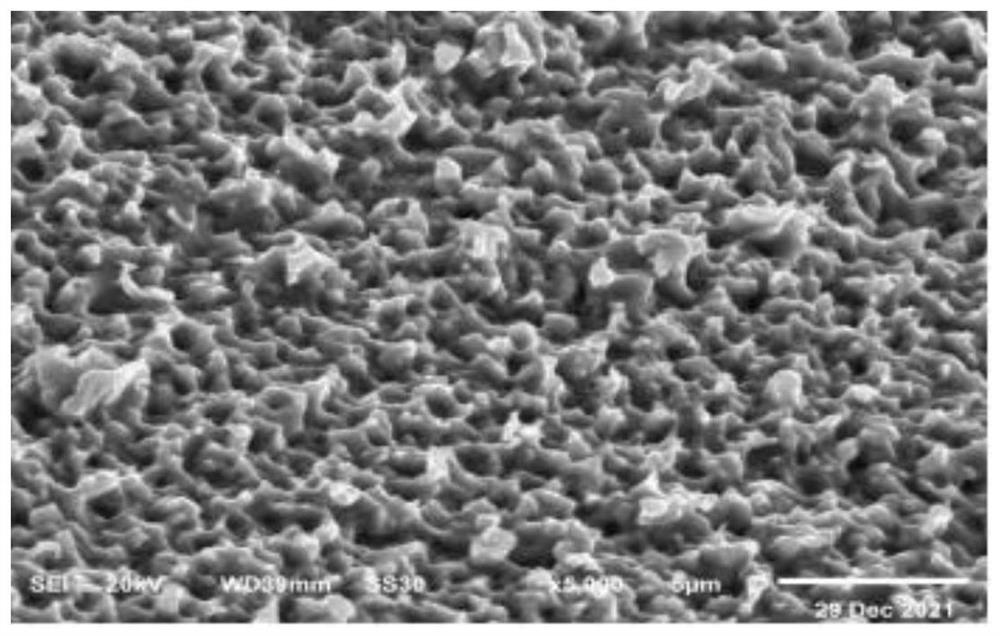

[0048] Spray roughening: use the roughening syrup at a temperature of 35 ℃, at a rate of 0.7Kg / cm 2 The spray pressure of the lead frame to be roughened is continuously sprayed for 90s, and the roughening liquid is kept at a 45° angle with the surface of the lead frame to be roughened during ...

Embodiment 2

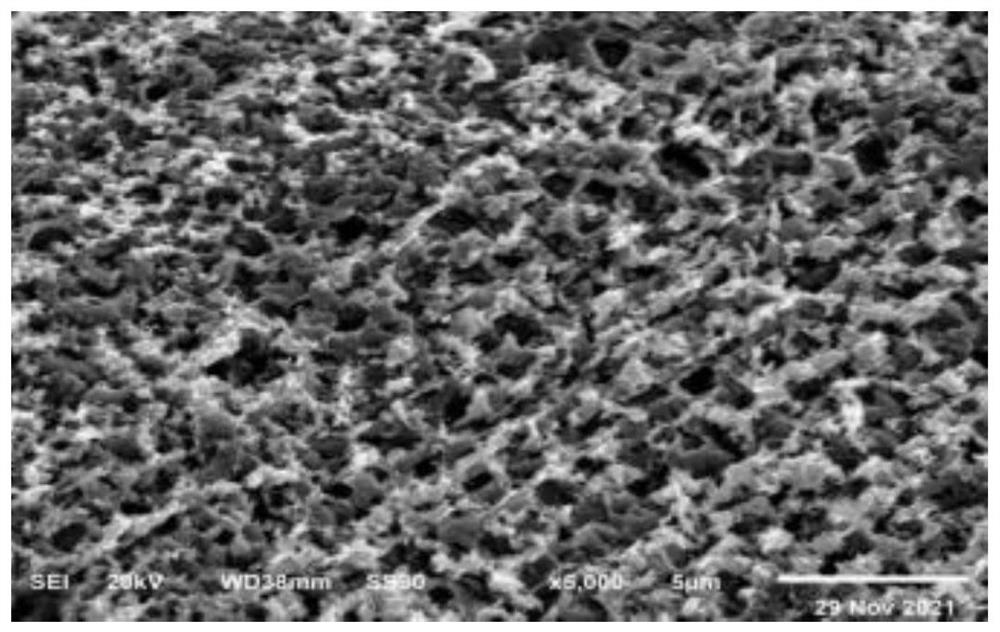

[0050] The difference between this example and Example 1 is that the current density during electroplating is controlled to be 2ASD, and the specific process conditions are shown in Table 1.

Embodiment 3

[0052] The difference between this example and Example 1 is that the current density during electroplating is controlled to be 5 ASD, and the specific process conditions are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com