Equipment and method for preparing crystals

An equipment and crystal technology, applied in the field of crystal growth equipment, can solve problems such as the inability to meet the temperature gradient, and achieve the effect of increasing the height of the temperature field and increasing the effective space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

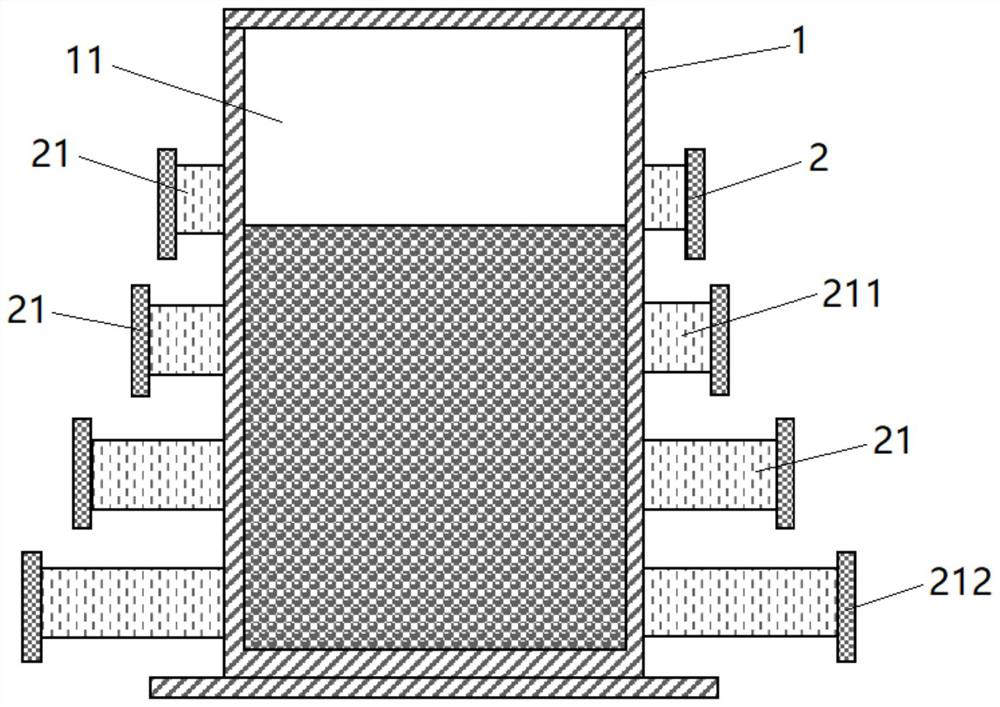

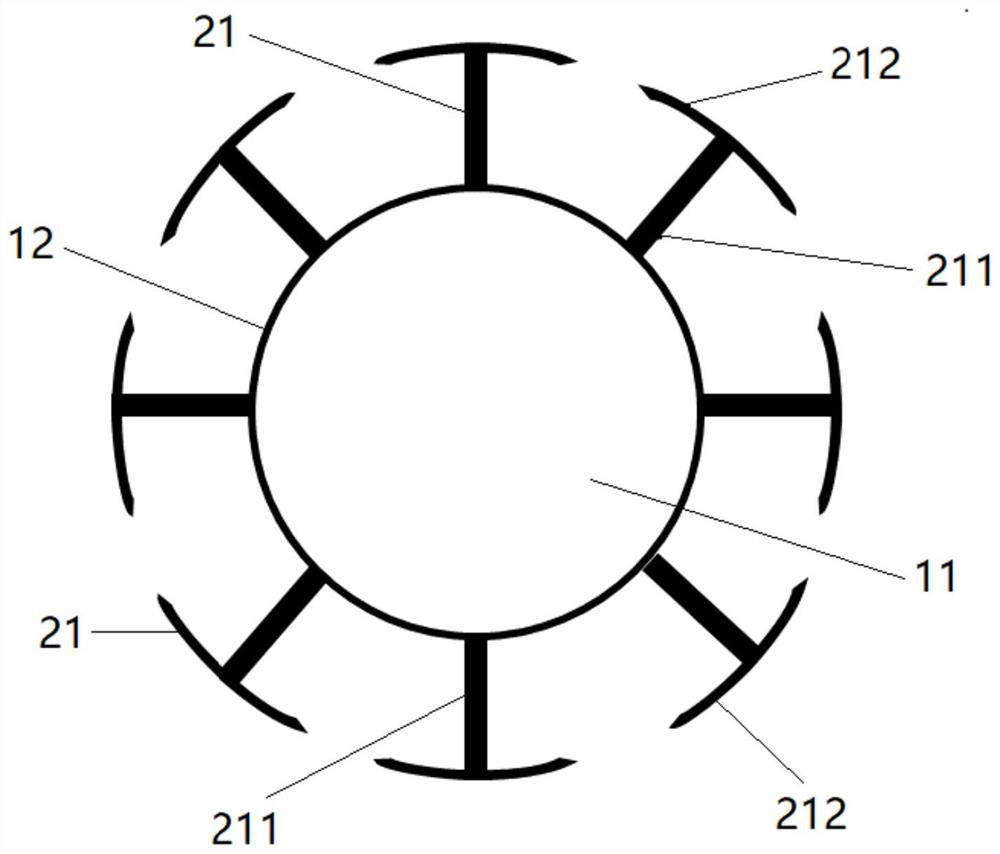

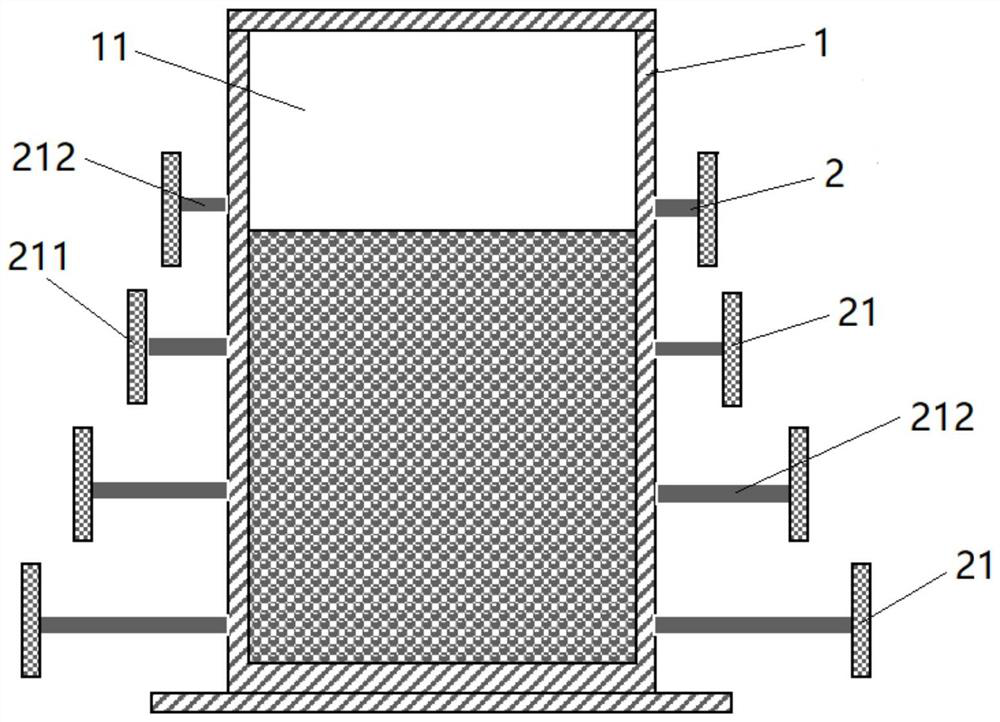

[0033] see figure 1 and figure 2In this embodiment, a device for preparing crystals includes: a device body, a heat source fixed to the device body, a growth chamber 1 fixed to the device body and located in the heat source, and a growth chamber 1 fixed to the growth chamber 1 and located between the heat source and the growth chamber There are at least two layers of temperature-regulating element sets 2 between 1 and 1. The growth chamber 1 has a accommodating cavity 11 for accommodating the source material. One end of the temperature-regulating element 21 of the temperature-regulating element group 2 is fixed to the growth chamber 1, and the other end is set apart from the heat source. , the lengths of the temperature regulating members 21 of the same layer of the temperature regulating member group 2 are equal, and the lengths of the temperature regulating members 21 are distributed in a gradient along the length extension direction of the accommodating cavity 11, and the ...

Embodiment 2

[0054] see Image 6 , a method for preparing crystals, applied to the above-mentioned equipment for preparing crystals, including:

[0055] Step S100 , according to the corresponding relationship between the length of the temperature regulating member and the temperature of the growth chamber, set at least two layers of temperature regulating member groups on the growth chamber in a gradient distribution along the lengthwise extending direction of the accommodating cavity.

[0056] Specifically, the lengths of the temperature adjustment elements of the same layer of temperature adjustment element groups are equal, and the lengths of the temperature adjustment elements of the adjacent temperature adjustment element groups are not equal. The longer the length of the temperature adjustment elements of the temperature adjustment element group, the corresponding The stronger the heat absorption capacity of the position, the higher the temperature of the corresponding position of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com