Waste straw recycling method and application thereof

A straw resource and straw technology, which is applied in the field of solid waste and waste straw resource treatment, can solve the problems of indigestion and absorption of livestock, nutrient loss of straw, and high cellulose content, so as to solve the problem of easy decay and deterioration, and improve the content of nutrients and lactic acid. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

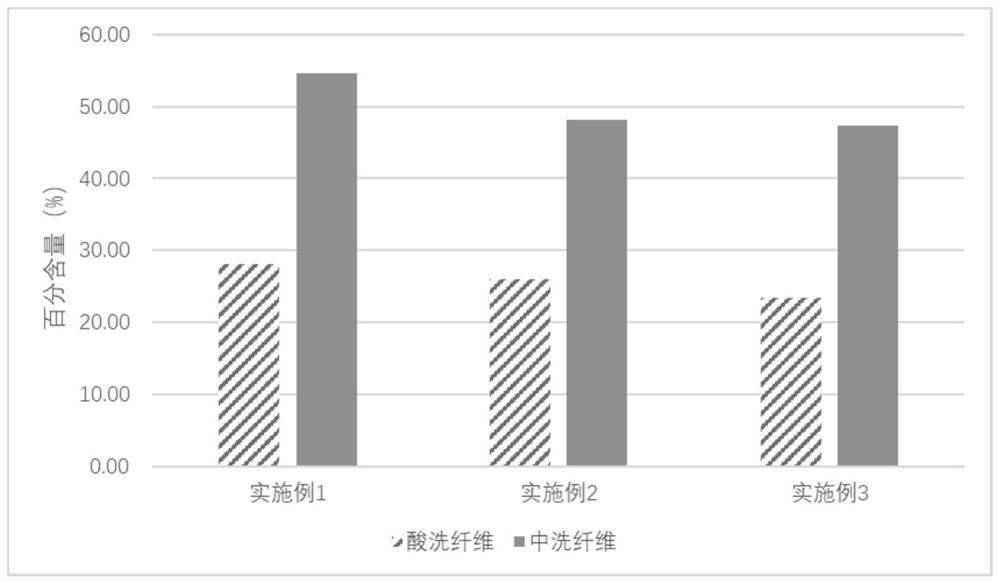

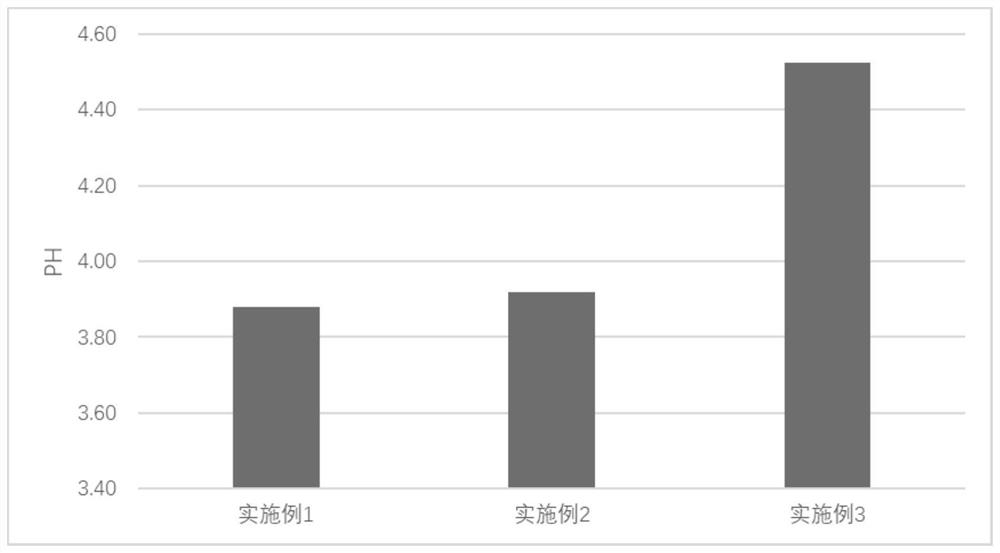

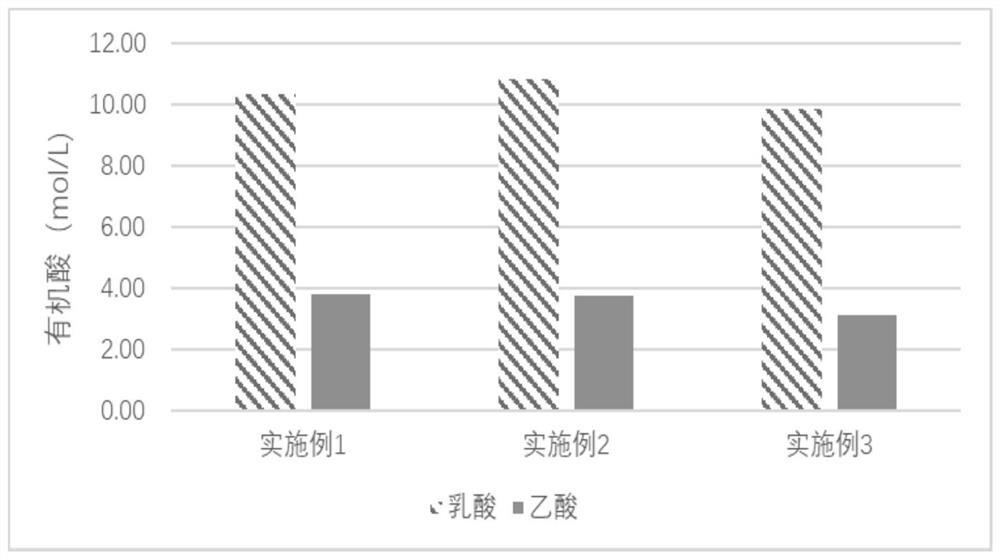

Embodiment 1

[0076] (1) pulverize 0.75kg of forage beet to 1-2cm pieces, beat again until the sugar beet particle is less than or equal to 1cm to obtain a beet slurry, add 0.625g of compound bacterial agent, and mix to obtain a starter;

[0077] (2) Take 4.25kg of corn stalk, crush and knead it to 1.5-2cm, add the starter prepared in step (1), and after mixing, fill it into a 10L fermentation tank, adjust the moisture content to 65%, and maximize the Press down, seal the lid with tape, store it in the dark at room temperature (15-25° C.), and ferment for 50 days to obtain yellow stock feed.

Embodiment 2

[0079] (1) pulverize 1.5kg of feed beet to 1-2cm pieces, beat again until the sugar beet particle is less than or equal to 1cm to obtain a beet slurry, add 0.625g of compound bacterial agent, and mix to obtain a starter;

[0080] (2) Take 3.5kg of corn stalk, crush and knead it to 1.5-2cm, add the starter prepared in step (1), and after mixing, fill it into a 10L fermentation tank, adjust the moisture content to 65%, and maximize the Press down, seal the lid with tape, store it in the dark at room temperature (15-25° C.), and ferment for 50 days to obtain yellow stock feed.

Embodiment 3

[0082] (1) pulverize 2.25kg of feed sugar beet to 1-2cm pieces, then beat until the sugar beet particle is less than or equal to 1cm to obtain a sugar beet slurry, add 0.625g of compound bacterial agent, and mix to obtain a starter;

[0083] (2) Take 2.75kg of corn stalk, crush and knead it to 1.5-2cm, add the starter prepared in step (1), and after mixing, fill it into a 10L fermentation tank, adjust the moisture content to 65%, and maximize the Press down, seal the lid with tape, store it in the dark at room temperature (15-25° C.), and ferment for 50 days to obtain yellow stock feed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com