Defoaming agent composition for acrylonitrile production device

A production device and defoaming agent technology, applied in the direction of foam dispersion/prevention, etc., can solve problems such as unstable operation, affecting the stable operation of the device, and large fluctuations in the pressure difference of the device, so as to achieve stable pressure difference, eliminate foam, and ensure stability running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

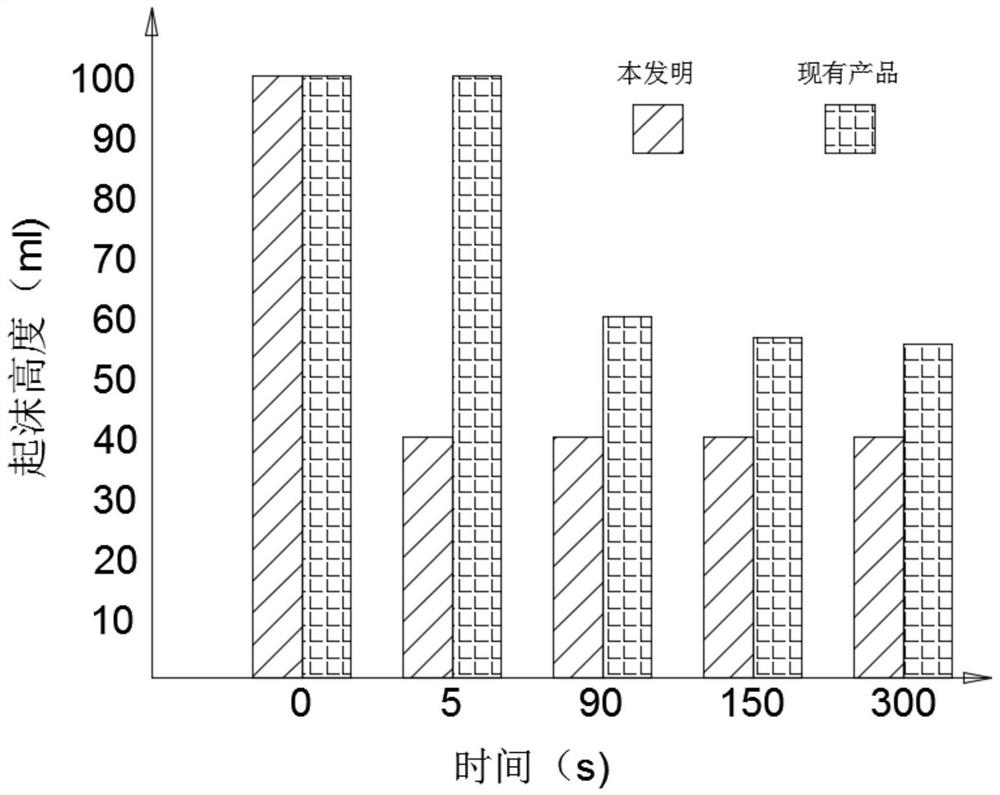

Embodiment 1

[0031] In the defoaming agent composition, the mass percentage of polyether is 32%, the mass percentage of nonionic surfactant is 68%, and the two are mixed; wherein the nonionic surfactant is polyethylene glycol fatty acid ester; defoaming agent The dosage of the composition was 150 ppm.

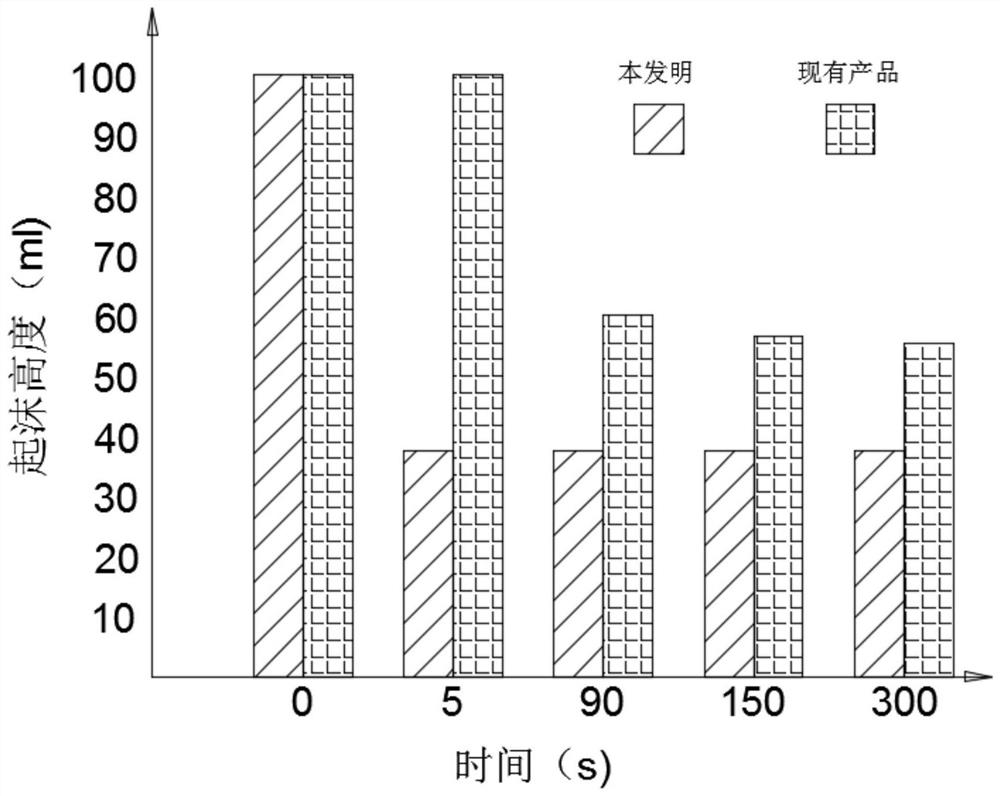

Embodiment 2

[0033] In the defoaming agent composition, the polyether used accounts for 55% by mass, and the nonionic surfactant accounts for 45% by mass, and the two are mixed; wherein the nonionic surfactant is fatty alcohol polyoxyethylene ether, polyoxyethylene Equal proportion mixture of block copolymer ester of ethylene and polyoxypropylene, the dosage of defoamer composition is 300ppm.

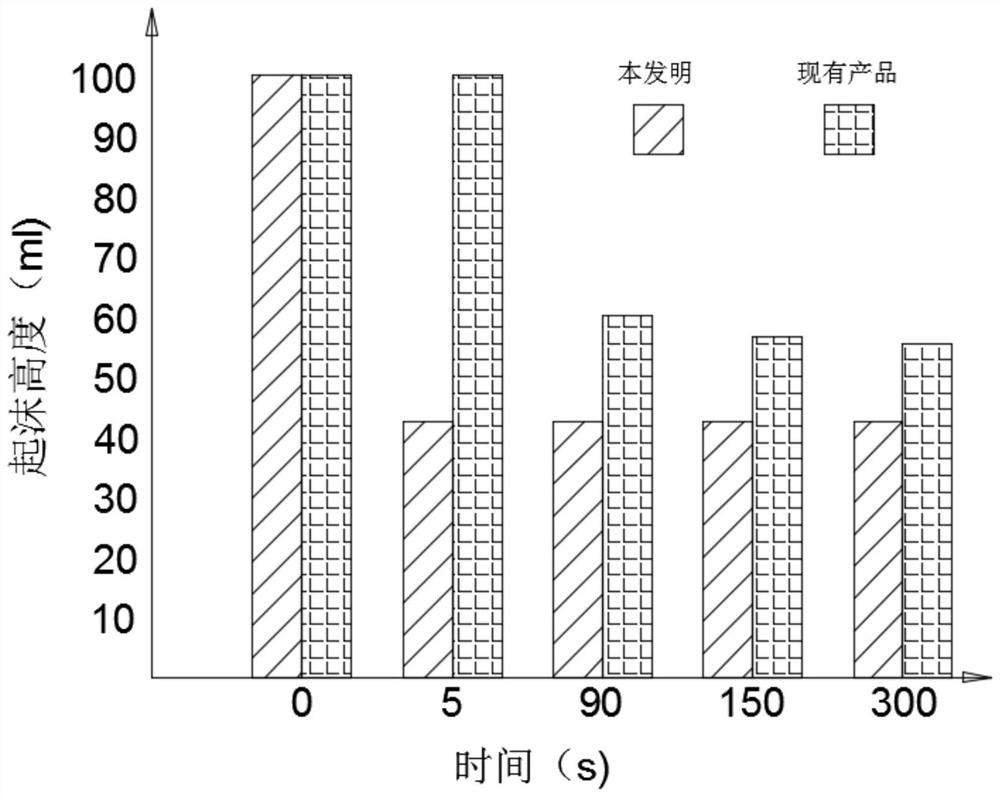

Embodiment 3

[0035] In the defoaming agent composition, the polyether used accounts for 83% by mass, and the nonionic surfactant accounts for 17% by mass, and the two are mixed; wherein the nonionic surfactant is polyethylene glycol fatty acid ester, alkane Base phenol polyoxyethylene ether is a mixture of equal proportions; the dosage of the defoamer composition is 450ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com