Method for degrading VOCs (Volatile Organic Compounds) tail gas of butanol and octanol device by utilizing separated bio-trickling filter

A bio-trickling filter tower and separation technology are applied in the field of degrading VOCs tail gas of a butanol-octanol device by using a separate bio-trickling filter tower, which can solve the problems of producing secondary pollutants and increasing the cost of enterprises, avoiding excessive consumption, The effect of reducing production and spraying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

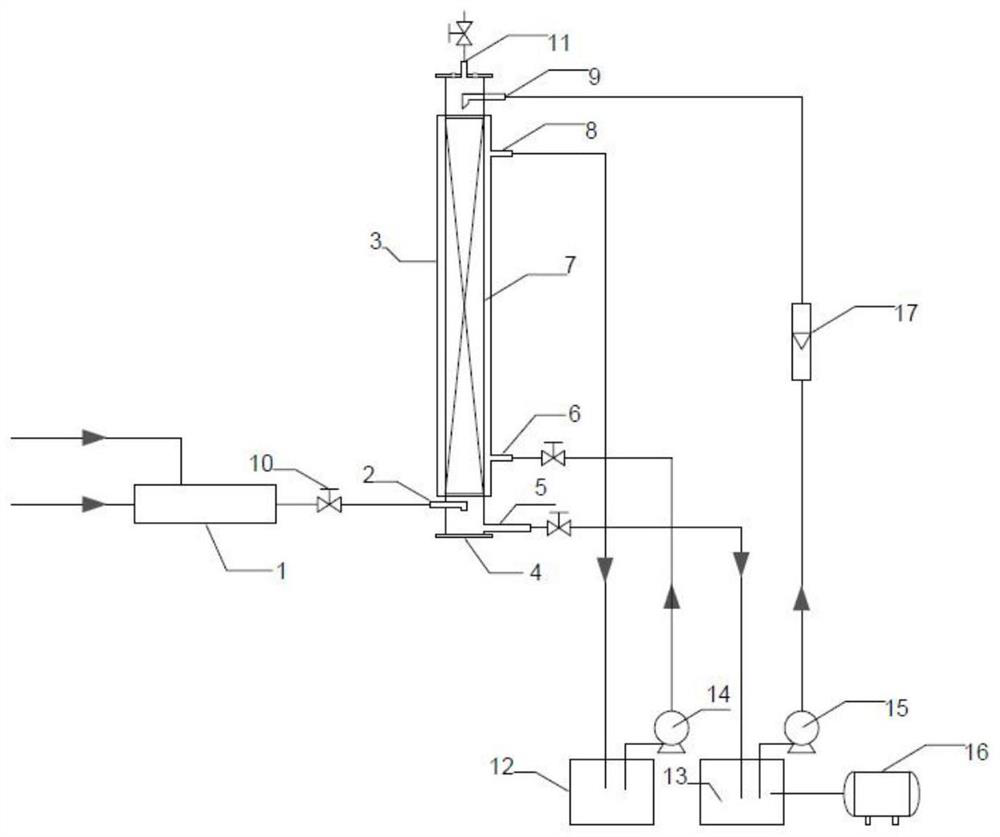

Method used

Image

Examples

Embodiment 1

[0050] The tail gas of the isobutyraldehyde storage tank TK08512A / B of Bohua Yongli's butyryl 1# unit was used as the source of VOCs in the method of degrading the VOCs tail gas of the butyryl-octanol unit by using a separate biological trickling filter tower. The specific process of the method in the present embodiment is as follows:

[0051] The activated sludge is filtered to obtain a clear liquid containing bacteria, and the clear liquid containing bacteria is used for inoculation and cultivation of the seed liquid. The seed solution was inoculated into a container with fresh nutrient solution at a ratio of 10%, and the container was placed in a water bath shaker for culture and acclimation; the seed solution was supplemented into the container in the water bath shaker at a ratio of 10% every 3 days. Isobutyraldehyde served as the sole source of carbon and energy during domestication.

[0052] Described fresh nutrient solution composition is: 9.25g / L K 2 HPO 4 , 2.88g / L...

Embodiment 2

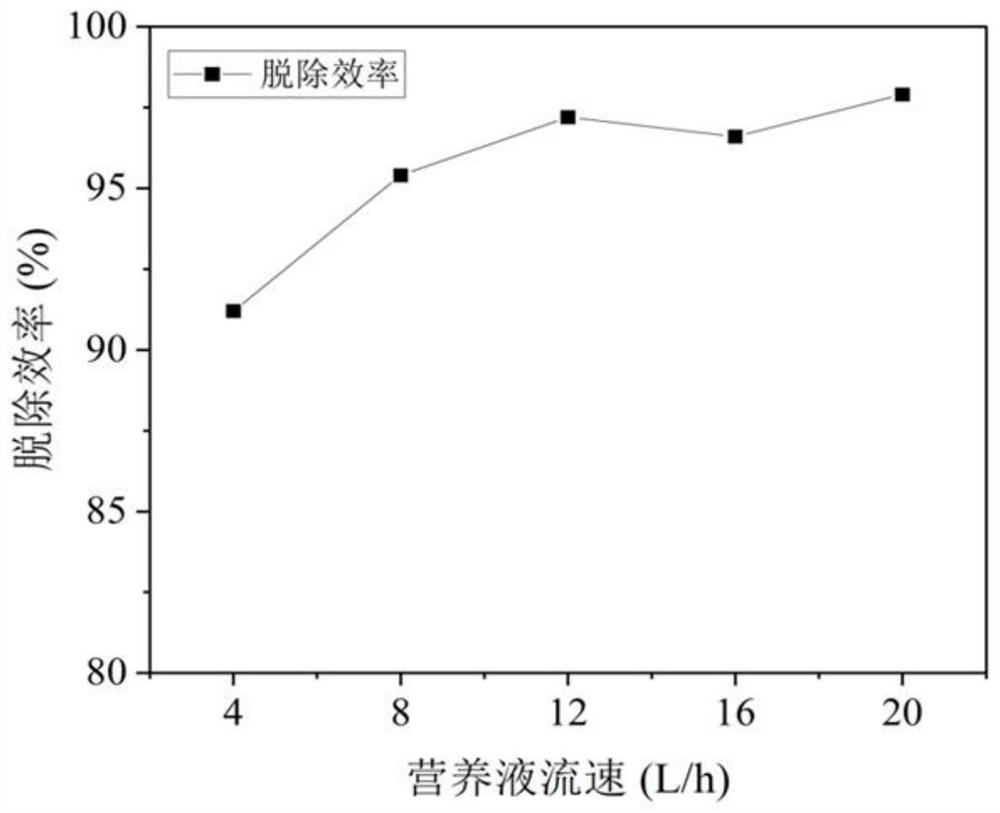

[0058] The tail gas of the n-butanol storage tank TK08506A of Bohua Yongli's butanol-octanol 1# plant was used as the source of VOCs in the method of degrading the VOCs tail gas of the butanol-octanol plant using a separate biological trickling filter tower. The specific operation process of the method in the present embodiment is as follows:

[0059] The activated sludge is filtered to obtain a clear liquid containing bacteria, and the clear liquid containing bacteria is used for inoculation and cultivation of the seed liquid. The seed solution was inoculated into a container with fresh nutrient solution at a ratio of 20%, and the container was placed in a water-bath shaker for culturing; the seed solution was supplemented at a ratio of 20% to the container in the water-bath shaker every 3 days. n-Butanol was used as the sole carbon and energy source during domestication.

[0060] Described fresh nutrient solution composition is: 9.25g / L K 2 HPO 4 , 2.88g / L KH 2 PO 4 , 0...

Embodiment 3

[0066] The unqualified octanol storage tank TK08509A / B tail gas of Bohua Yongli's butanol-octanol 1# device is used as the source of VOCs in the method of the present invention for degrading the VOCs tail gas of the butanol-octanol device by using a separate biological trickling filter tower. The specific operation process of the method in the present embodiment is as follows:

[0067] The activated sludge is filtered to obtain a clear liquid containing bacteria, and the clear liquid containing bacteria is used for inoculation and cultivation of the seed liquid. The seed liquid was inoculated into a container with fresh nutrient solution at a ratio of 25%, and the container was placed in a water bath shaker for cultivation and acclimation; the seed liquid was supplemented with a ratio of 25% to the container in the water bath shaker every 3 days. Octanol was used as the sole carbon and energy source during domestication.

[0068] Described fresh nutrient solution composition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com