Processing method of heat preservation and decoration integrated plate

A processing method and integrated board technology, applied in chemical instruments and methods, lamination devices, coatings, etc., can solve the problems of separation, peeling off, and affect the performance durability of the topcoat and the board, and achieve good physical and mechanical properties and water resistance. The effect of improving the bonding force and improving the environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

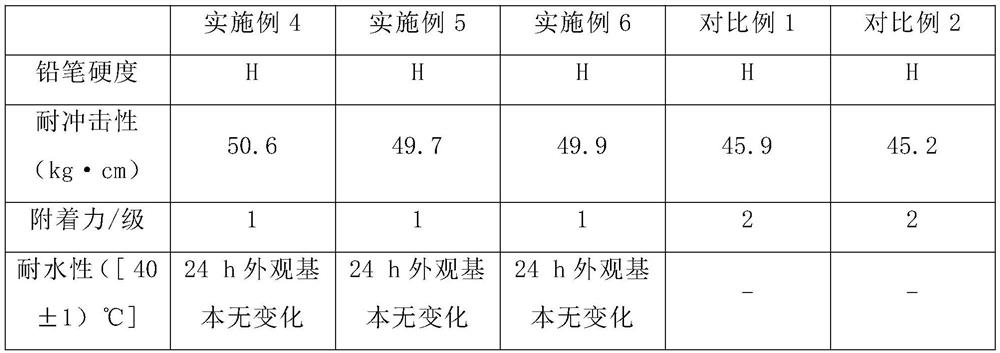

Examples

Embodiment 1

[0024] To prepare the topcoat:

[0025] Add the water-based hydroxy acrylic resin into the paint mixing kettle, slowly add the water-based color paste under constant stirring at 300 r / min, stir evenly after adding, increase the speed to 500 r / min, and slowly add deionized water, diethylene glycol butyl ether, After adding the water-based defoamer and water-based leveling agent, stir evenly, then slowly add the water-based thickener under stirring, stir at 500 r / min for 10 minutes, adjust the viscosity, filter and pack with a 120-mesh vibrating screen to obtain the substrate; use When the substrate and the isocyanate curing agent are mixed uniformly according to the mass ratio, the topcoat is obtained;

[0026] Wherein, in parts by weight, the consumption of each raw material is as follows: 50g of hydroxy acrylic resin, 30g of water-based color paste, 3g of deionized water, 2g of diethylene glycol butyl ether, 0.1g of water-based defoamer, 0.1g of water-based leveling agent, T...

Embodiment 2

[0029] To prepare the topcoat:

[0030] Add the water-based hydroxy acrylic resin into the paint mixing kettle, slowly add the water-based color paste under constant stirring at 300 r / min, stir evenly after adding, increase the speed to 500 r / min, and slowly add deionized water, diethylene glycol butyl ether, After adding the water-based defoamer and water-based leveling agent, stir evenly, then slowly add the water-based thickener under stirring, stir at 500 r / min for 13 minutes, adjust the viscosity, filter and pack with a 120-mesh vibrating screen to obtain the substrate; use When the substrate and the isocyanate curing agent are mixed uniformly according to the mass ratio, the topcoat is obtained;

[0031] Wherein, in parts by weight, the consumption of each raw material is as follows: 55g of hydroxy acrylic resin, 33g of water-based color paste, 4g of deionized water, 2.5g of diethylene glycol butyl ether, 0.2g of water-based defoamer, 0.2g of water-based leveling agent, ...

Embodiment 3

[0034] To prepare the topcoat:

[0035] Add the water-based hydroxy acrylic resin into the paint mixing kettle, slowly add the water-based color paste under constant stirring at 300 r / min, stir evenly after adding, increase the speed to 500 r / min, and slowly add deionized water, diethylene glycol butyl ether, After adding the water-based defoamer and water-based leveling agent, stir evenly, then slowly add the water-based thickener under stirring, stir at 500 r / min for 15 minutes, adjust the viscosity, filter and pack with a vibrating screen 120 mesh to obtain the substrate; use When the substrate and the isocyanate curing agent are mixed uniformly according to the mass ratio, the topcoat is obtained;

[0036] Wherein, in parts by weight, the consumption of each raw material is as follows: 60g of hydroxy acrylic resin, 35g of water-based color paste, 5g of deionized water, 3g of diethylene glycol butyl ether, 0.3g of water-based defoamer, 0.3g of water-based leveling agent, 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com