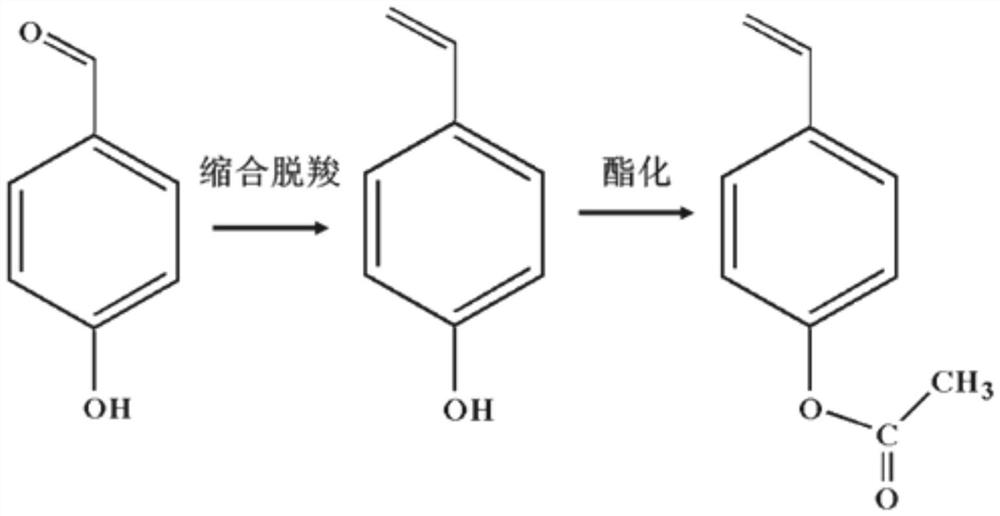

Method for preparing p-acetoxystyrene by one-pot method

A technology of acetoxystyrene and p-hydroxybenzaldehyde, applied in the field of preparation of organic compounds, can solve the problems of high reaction temperature and equipment requirements, unfavorable large-scale industrial production, high equipment requirements and operational requirements, and achieves the reaction Low cost of raw materials, low requirements for reaction equipment, and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing p-acetoxystyrene by one-pot method, the steps are as follows: 50g of p-hydroxybenzaldehyde, 85g of malonic acid, 8.1g of ethylenediamine, 0.072g of 4-tert-butylcatechol are put into 500ml of reaction in 180ml DMF, in N 2 The reaction was carried out at 130 °C for 6 h, 90 ml of n-hexane was added to the reaction solution, stirred for 20 min, 45.57 g of triethylamine and 45.9 g of acetic anhydride were added, and the reaction was carried out at 40 ° C for 5 h, and the organic phase was washed twice with water. waterNaSO 4 After drying, the solvent was distilled off under reduced pressure, and the final yield of p-acetoxystyrene was 76%.

Embodiment 2

[0027] A one-pot method for preparing p-acetoxystyrene, the steps are as follows: 50g p-hydroxybenzaldehyde, 85g malonic acid, 8.1g ethylenediamine, 0.09g phenothiazine are put into a 500ml reactor, dissolved in 180ml DMF in N 2 The reaction was carried out at 130 °C for 6 h, 90 ml of n-hexane was added to the reaction solution, stirred for 20 min, 45.57 g of triethylamine and 45.9 g of acetic anhydride were added, and the reaction was carried out at 40 ° C for 5 h, and the organic phase was washed twice with water. waterMgSO 4 After drying, the solvent was distilled off under reduced pressure, and the final yield of p-acetoxystyrene was 75%.

Embodiment 3

[0029] A one-pot method for preparing p-acetoxystyrene, comprising the steps of: putting 50g of p-hydroxybenzaldehyde, 85g of malonic acid, 11.6g of morpholine, and 0.072g of 4-tert-butylcatechol into a 500ml reactor , dissolved in 180ml DMF, in N 2 The reaction was carried out at 130 °C for 6 h, 90 ml of n-hexane was added to the reaction solution, stirred for 20 min, 45.57 g of triethylamine and 45.9 g of acetic anhydride were added, and the reaction was carried out at 40 ° C for 5 h, and the organic phase was washed twice with water. waterNaSO 4 After drying, the solvent was distilled off under reduced pressure, and the final yield of p-acetoxystyrene was 73%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com