Rosin-based anion macroporous adsorption resin and preparation method thereof

An anion and pore adsorption technology, which is applied in the direction of chemical instruments and methods, and other chemical processes, can solve the problems of environmental hazards, non-green environmental protection, etc., and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

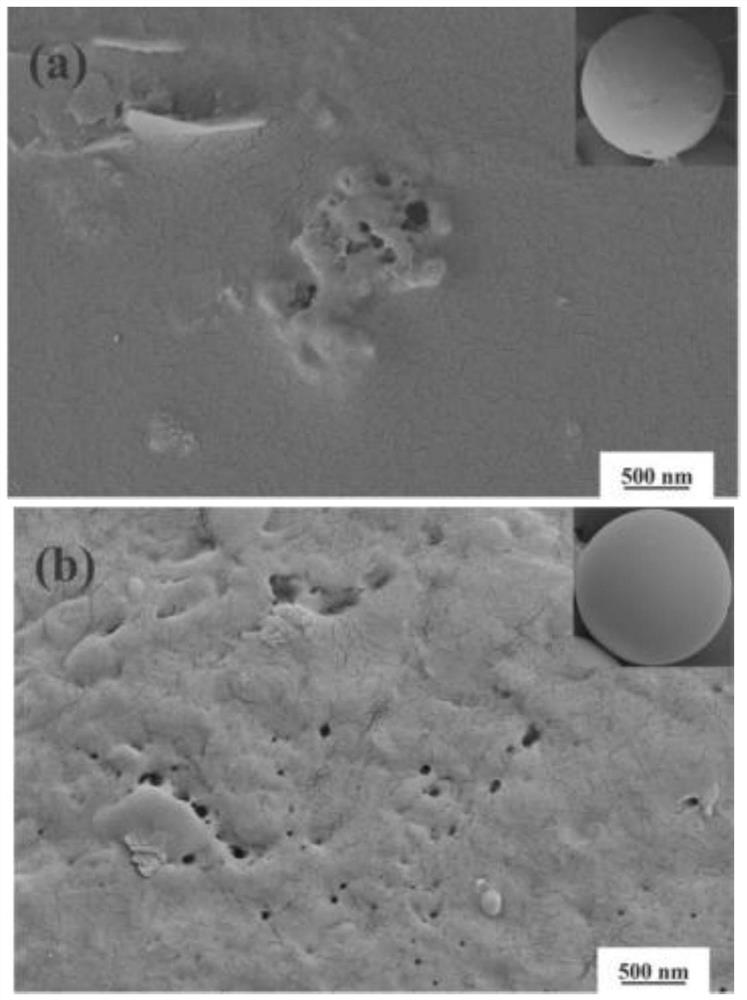

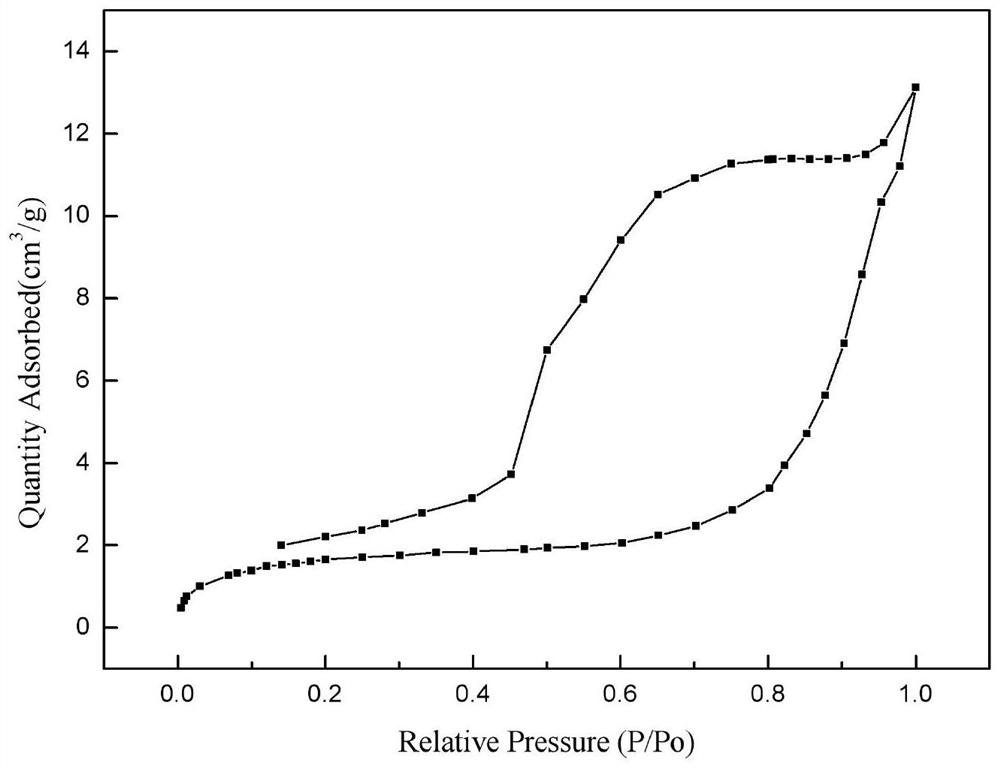

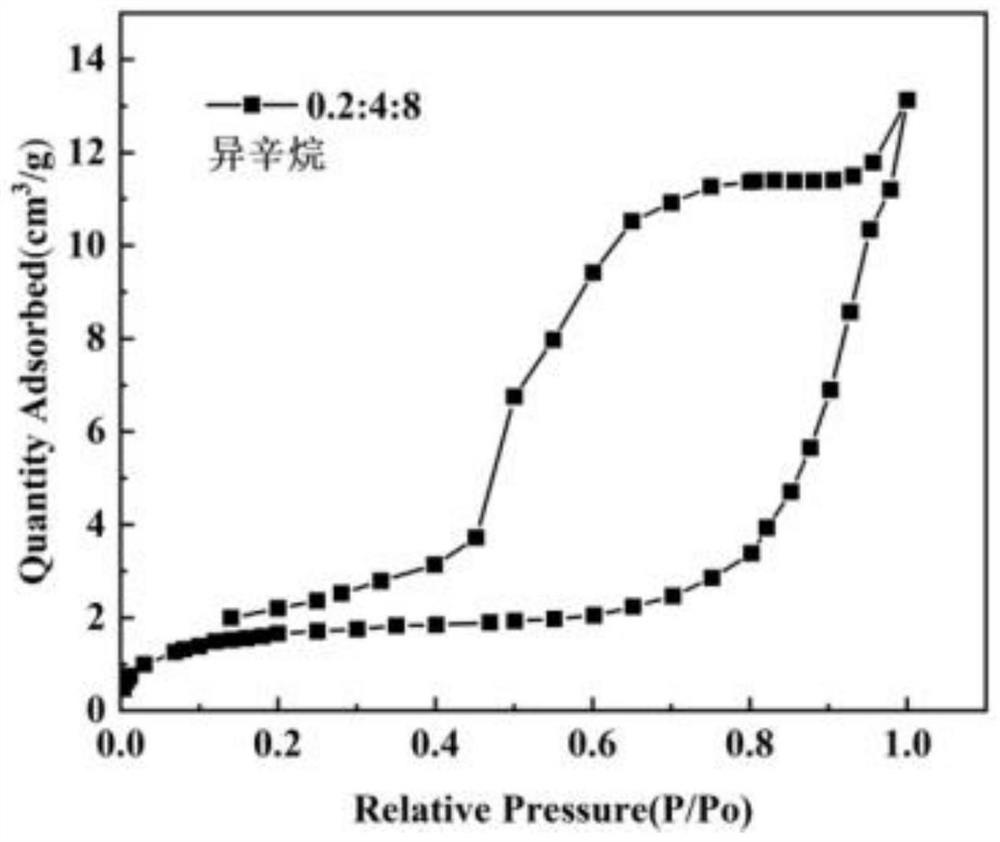

Image

Examples

Embodiment 1

[0029] (1) Mix 200 g of deionized water, 0.1 g of polyvinyl alcohol, and 0.05 g of sodium dodecyl sulfonate (the mass ratio of deionized water, polyvinyl alcohol, and sodium dodecyl sulfonate is 100:0.05:0.025 ), heated to 100°C to completely dissolve the polyvinyl alcohol to obtain an aqueous phase.

[0030] (2) Dissolve 1 g of hydrogenated rosin (β-acryloyloxyethyl) ester in 3 g of ethyl acetate, use ultrasonic waves to promote the dissolution, and after the hydrogenated rosin (β-acryloyloxyethyl) ester is completely dissolved, then Add 30 g of dimethylaminoethyl methacrylate, 0.1 g of azobisisobutyronitrile (hydrogenated rosin (β-acryloyloxyethyl) ester, ethyl acetate, dimethylaminoethyl methacrylate, azo The mass ratio of diisobutyronitrile is 1:3:30:0.1), ultrasonically oscillated for 2-10 min, and the mixture is uniformly dispersed to obtain an oil phase.

[0031] (3) Add the prepared oil phase to the water phase, then heat up and polymerize at a stirring speed of 140 r...

Embodiment 2

[0034] (1) Mix 200 g of deionized water, 0.1 g of polyvinyl alcohol, and 0.05 g of sodium dodecyl sulfonate (the mass ratio of deionized water, polyvinyl alcohol, and sodium dodecyl sulfonate is 100:0.05:0.025 ), heated to 100°C to completely dissolve the polyvinyl alcohol to obtain an aqueous phase.

[0035] (2) Dissolve 2 g of hydrogenated rosin (β-acryloyloxyethyl) ester in 6 g of ethyl acetate, use ultrasonic waves to promote the dissolution, and after the hydrogenated rosin (β-acryloyloxyethyl) ester is completely dissolved, then Add 30 g of dimethylaminoethyl methacrylate, 0.1 g of azobisisobutyronitrile (hydrogenated rosin (β-acryloyloxyethyl) ester, ethyl acetate, dimethylaminoethyl methacrylate, azo The mass ratio of diisobutyronitrile is 2:6:30:0.1), ultrasonically oscillated for 2-10 min, and the mixture is uniformly dispersed to obtain an oil phase.

[0036] (3) Add the prepared oil phase to the water phase, then heat up and polymerize at a stirring speed of 140 r...

Embodiment 3

[0039] (1) Mix 200 g of deionized water, 0.1 g of polyvinyl alcohol, and 0.05 g of sodium dodecyl sulfonate (the mass ratio of deionized water, polyvinyl alcohol, and sodium dodecyl sulfonate is 100:0.05:0.025 ), heated to 100°C to completely dissolve the polyvinyl alcohol to obtain an aqueous phase.

[0040] (2) Dissolve 3 g of hydrogenated rosin (β-acryloyloxyethyl) ester in 9 g of ethyl acetate, use ultrasonic waves to promote the dissolution, and after the hydrogenated rosin (β-acryloyloxyethyl) ester is completely dissolved, then Add 30 g of dimethylaminoethyl methacrylate, 0.1 g of azobisisobutyronitrile (hydrogenated rosin (β-acryloyloxyethyl) ester, ethyl acetate, dimethylaminoethyl methacrylate, azo The mass ratio of diisobutyronitrile is 3:9:30:0.1), ultrasonically oscillated for 2-10 min, and dispersed evenly to obtain an oil phase.

[0041](3) Add the prepared oil phase to the water phase, then heat up and polymerize at a stirring speed of 140 rad / min. When the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com