Modified solid amine adsorbent for treating CO2-containing industrial waste gas and preparation method thereof

A technology of industrial waste gas and solid amine, applied in the direction of separation methods, chemical instruments and methods, and other chemical processes, can solve problems such as difficult long-term continuous operation, improve recovery rate and cycle life, simple preparation method, reduce The effect of mutual contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

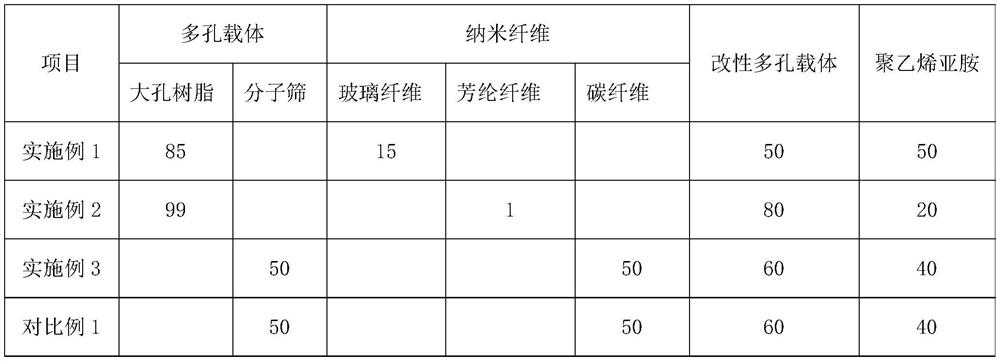

[0035] The preparation process of embodiment 1-3 is as follows:

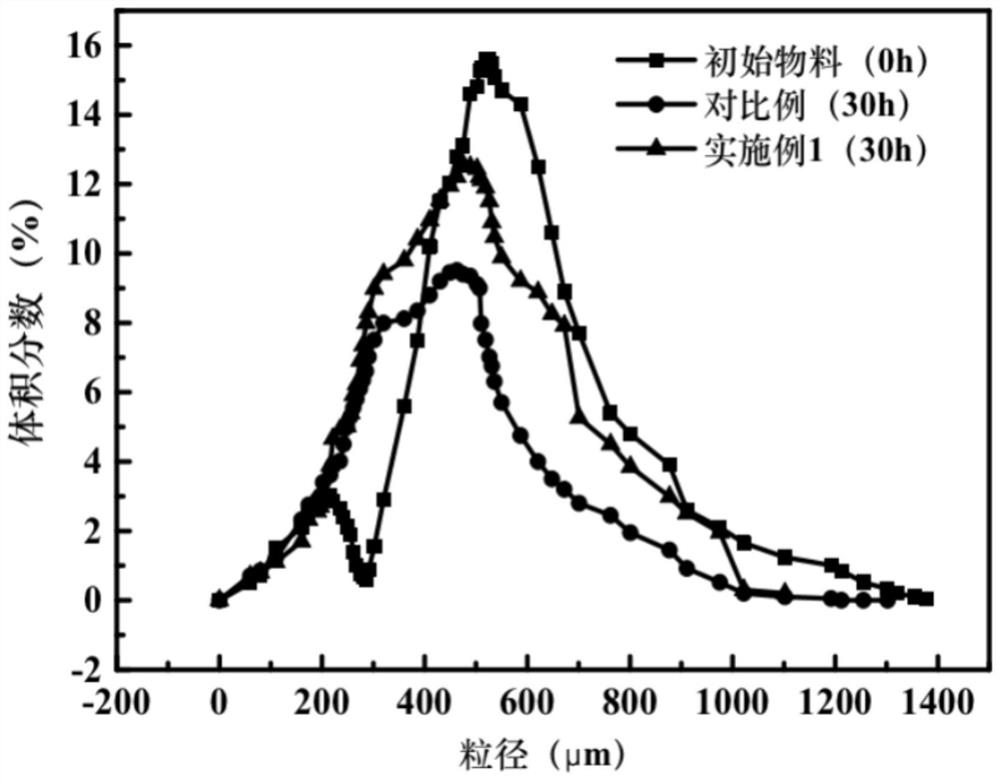

[0036] Weigh the components according to the proportions in Table 1, add the sieved porous carrier, purified nanofibers and excess methanol into the reaction flask, continue stirring at a speed of 45 rpm, and after fully dispersed, the mixed solution It was placed in an oven at 80°C to dry for 2 hours, and after drying, a modified porous material with nanofibers wrapped on its surface was obtained.

[0037] The modified porous material was added to the reaction flask, then ethanol and 50wt.% polyethyleneimine were added, the stirring speed was adjusted to 50 rpm, the temperature was raised to 60 °C and the stirring was continued, the organic amine solution could be naturally adsorbed on the In the pores of the material, stir until the organic solvent volatilizes. After the solvent volatilizes, there is no liquid in the reaction flask. Then, the reaction flask is transferred to a vacuum drying oven and heated at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com