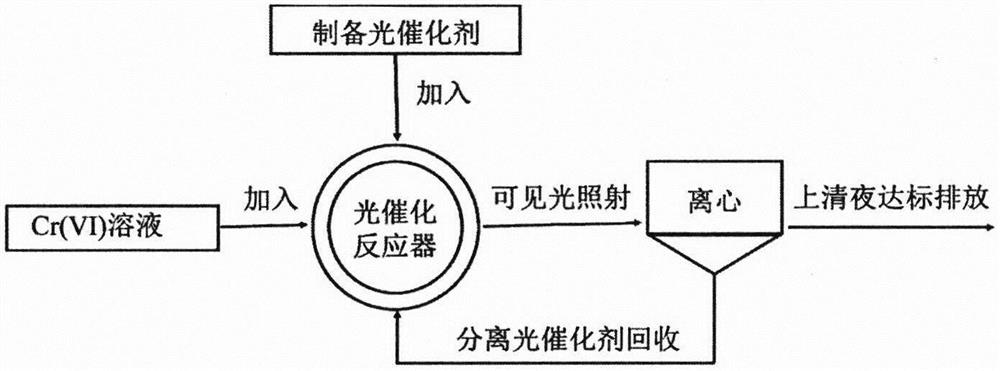

Method for removing hexavalent chromium in wide pH range by using ultrathin Bi24O31Br10 nanosheet through photocatalytic reduction

A bi24o31br10, hexavalent chromium technology, applied in chemical instruments and methods, physical/chemical process catalysts, reduced water/sewage treatment, etc., can solve problems such as low quantum yield, low solar energy utilization efficiency, and difficulty in removing hexavalent chromium. , to achieve the effects of good stability, simple removal process and operation, and high light energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

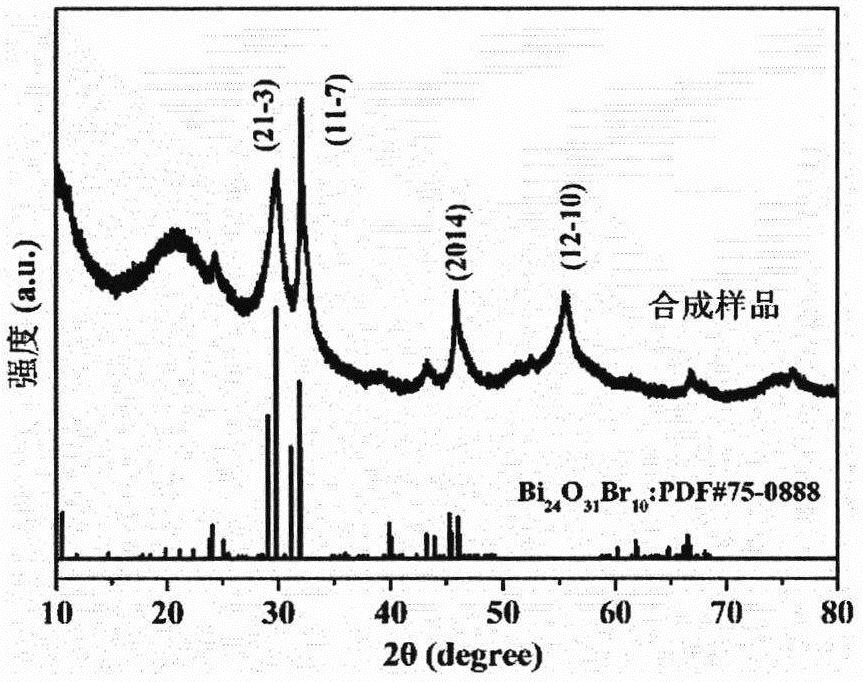

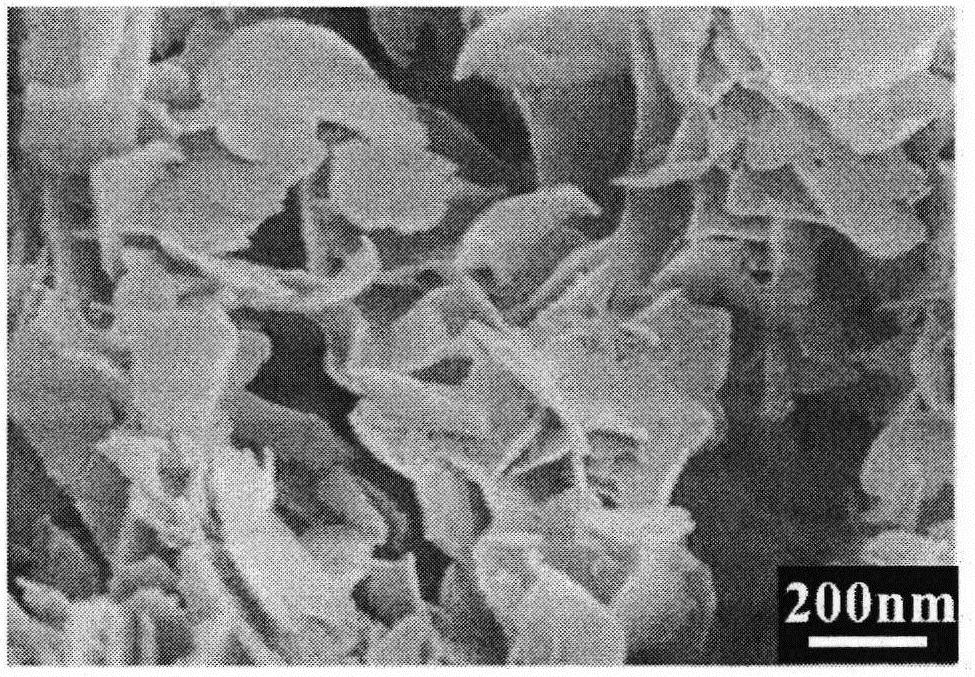

[0026] Preparation of ultrathin Bi 24 O 31 Br 10 Nanosheet photocatalysts. First measure 40ml of deionized water into a 100mL beaker, then dissolve 1mmol (0.119g) of analytically pure KBr (CAS: 7758-02-3) in deionized water, and then take 4mmol (0.697g) of analytically pure L-precipitation Amino acid (CAS: 74-79-3) was dissolved in the above solution under magnetic stirring. After 2 minutes of magnetic stirring, 1 mmol (0.485 g) of analytically pure Bi(NO) was added to the above clear and transparent solution. 3 ) 3 ·5H 2 O(CAS: 10035-06-0). The obtained mixture solution was continuously magnetically stirred at room temperature for 1 hour, and a pale yellow precipitate was formed at the same time. The formed precipitate was collected by centrifugation, washed three times with distilled water and ethanol, respectively, to remove the impurity ions attached to the surface, and finally dried in a blast drying oven at 60 °C for 12 h, and the dried samples were ground to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com