Method of removing pollutant in water with mechanical ball-milling activated zero-valent aluminum

A technology of mechanical ball milling and zero-valent aluminum, which is applied in the direction of water pollutants, chemical instruments and methods, water/sewage treatment, etc., can solve the problem of low removal rate of pollutants in water, and achieve simple operation, high-efficiency removal, and cheap medicines Easy to get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

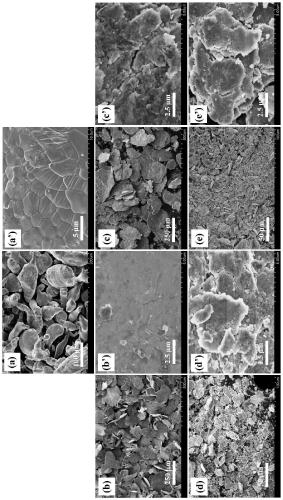

[0027] Add a total of 300g of zirconia grinding balls to a stainless steel ball milling tank with a volume of 500mL, and add grinding balls with diameters of 10mm, 8mm and 5mm at a mass ratio of 1:3:6, that is, the masses are 30g, 90g and 180g respectively ; Weigh 5.0g of zero-valent aluminum powder (75 ~ 150μm, specific surface area 0.35m 2 / g) is transferred to a ball mill jar, that is, the mass ratio of zero-valent aluminum powder to grinding balls is 1:60, then add 0.5mL of absolute ethanol (the mass ratio of zero-valent aluminum powder is 7.8:100), and vacuumize Finally, nitrogen is filled to ensure that the tank is an inert atmosphere, and the ball mill tank is symmetrically placed in a planetary ball mill, and the set speed is 300rpm. Every 30min in the ball mill, stop running for 10min, and the ball milling time is 0.5h;

Embodiment 2

[0029] Repeat embodiment 1 by the same steps as described, and adjust the ball milling time to 1.0h;

Embodiment 3

[0031] Repeat embodiment 1 by the same steps as described, and adjust the ball milling time to 2.0h;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com