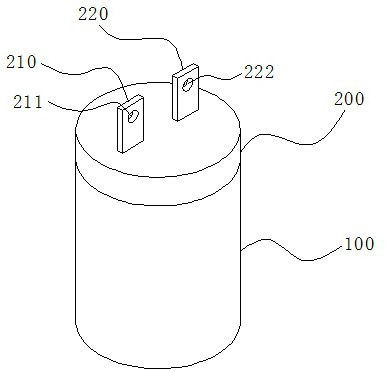

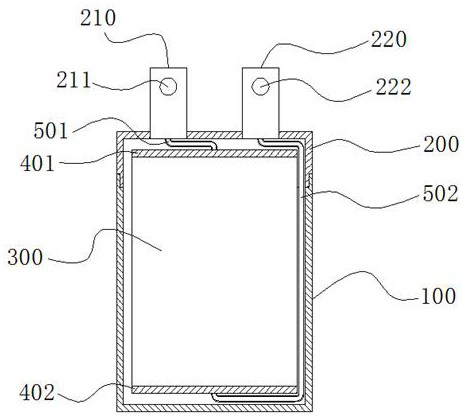

Energy storage film capacitor

A thin-film capacitor and energy storage technology, applied in the field of capacitors, to achieve the effect of improving connection performance and improving charge and discharge capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

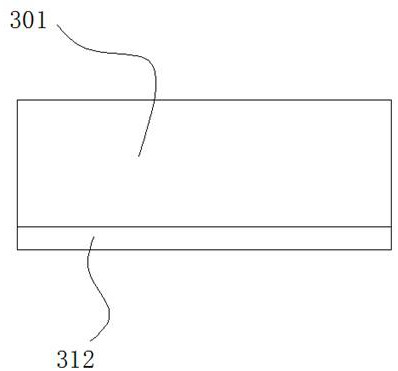

[0053] Example 1: Preparation of First Polypropylene Base Film 310

[0054] A preparation method of the first polypropylene base film 310, comprising the following steps:

[0055] (1) Mix manganese dioxide, vanadium pentoxide and water, ultrasonically disperse, then add polymer (polyvinyl alcohol), then heat up to 80°C, keep warm for 2 hours, dry under vacuum conditions, and ball mill to obtain modified Manganese dioxide and vanadium pentoxide, the weight ratio of manganese dioxide, vanadium pentoxide and polymer is 1:0.2:12, and the weight ratio of manganese dioxide and water is 1:50; modified manganese dioxide and five The mesh number of vanadium oxide is 150-160 mesh;

[0056] (2) Mix polypropylene, styrene-maleic anhydride copolymer and polyester resin, the weight ratio of polypropylene, styrene-maleic anhydride copolymer and polyester resin is 1:1.5:2, and heat to molten state , and then add the modified manganese dioxide obtained in step (1), vanadium pentoxide and sil...

Embodiment 2

[0057] Example 2: Preparation of the first polypropylene base film 310;

[0058] A preparation method of the first polypropylene base film 310, comprising the following steps:

[0059] (1) Mix manganese dioxide, vanadium pentoxide and water, ultrasonically disperse, then add polymer (polyethylene wax), then heat up to 90°C, keep warm for 2 hours, dry under vacuum conditions, and ball mill to obtain modified Manganese dioxide and vanadium pentoxide, the weight ratio of manganese dioxide, vanadium pentoxide and polymer is 1:0.3:14, and the weight ratio of manganese dioxide and water is 1:60; modified manganese dioxide and five The mesh number of vanadium oxide is 150-160 mesh;

[0060] (2) Mix polypropylene, styrene-maleic anhydride copolymer and polyester resin, the weight ratio of polypropylene, styrene-maleic anhydride copolymer and polyester resin is 1:2:5, and heat to molten state , and then add the modified manganese dioxide and vanadium pentoxide prepared in step (1), s...

Embodiment 3

[0061] Example 3: Preparation of the first polypropylene base film 310;

[0062] A preparation method of the first polypropylene base film 310, comprising the following steps:

[0063] (1) Mix manganese dioxide, vanadium pentoxide and water, ultrasonically disperse, then add polymer (polyethylene glycol), then heat up to 95°C, keep the temperature for 3 hours, dry under vacuum conditions, and ball mill to obtain the modified product. manganese dioxide and vanadium pentoxide, the weight ratio of manganese dioxide, vanadium pentoxide and polymer is 1:0.5:18, and the weight ratio of manganese dioxide and water is 1:90; modified manganese dioxide and The mesh number of vanadium pentoxide is 150-160 mesh;

[0064] (2) Mix polypropylene, styrene-maleic anhydride copolymer and polyester resin, the weight ratio of polypropylene, styrene-maleic anhydride copolymer and polyester resin is 1:2:4.5, and heat to molten state , and then add the modified manganese dioxide and vanadium pento...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Breakdown strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com