Preparation method of composite nanoparticle aluminum adjuvant

An aluminum adjuvant and nanoparticle technology, applied in the field of preparation of nanocomposite vaccine adjuvant, can solve the problems of lack of ability of aluminum salt adjuvant to induce Th1 type immune response, inability to induce mucosal immune response, etc., and achieve good delivery and immunity. Enhanced, increased yield, good immune response effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

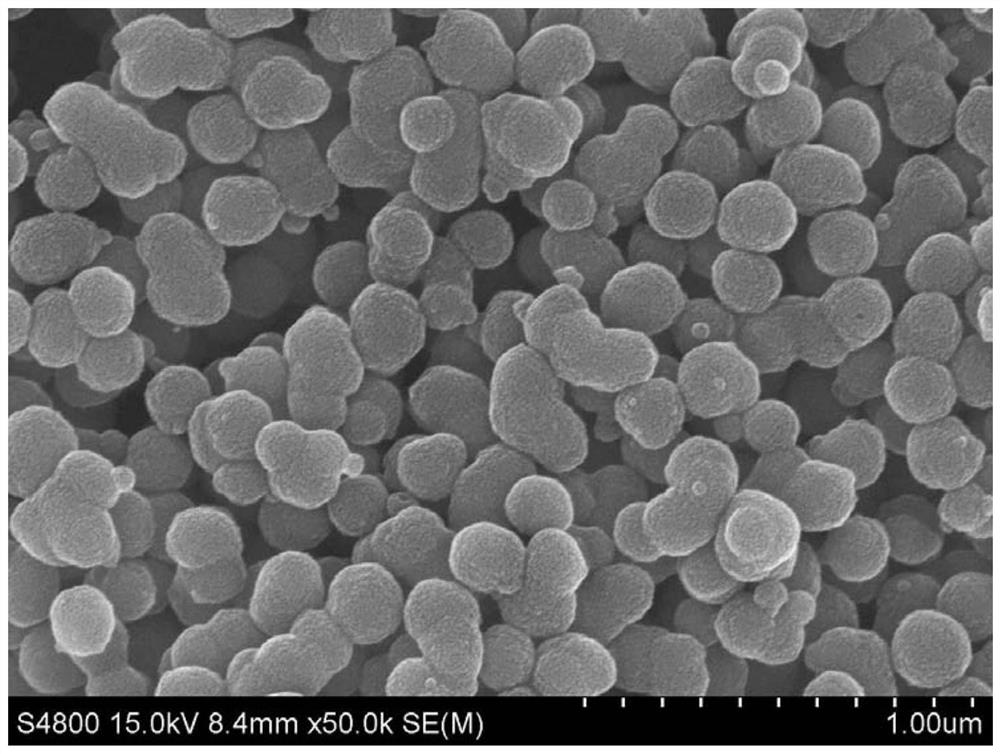

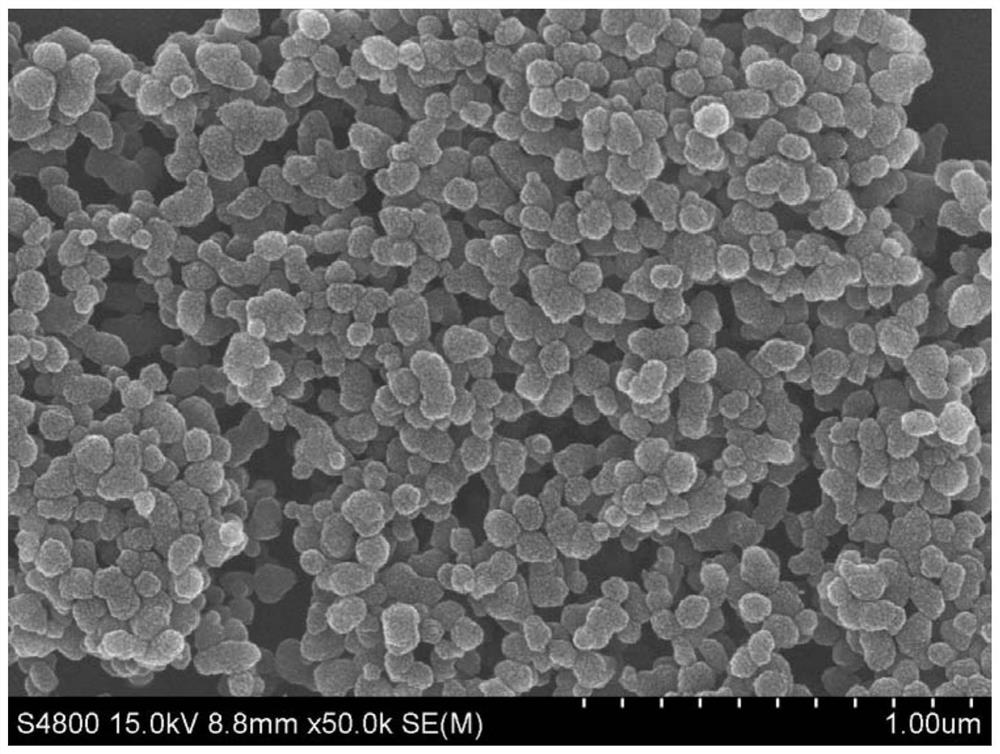

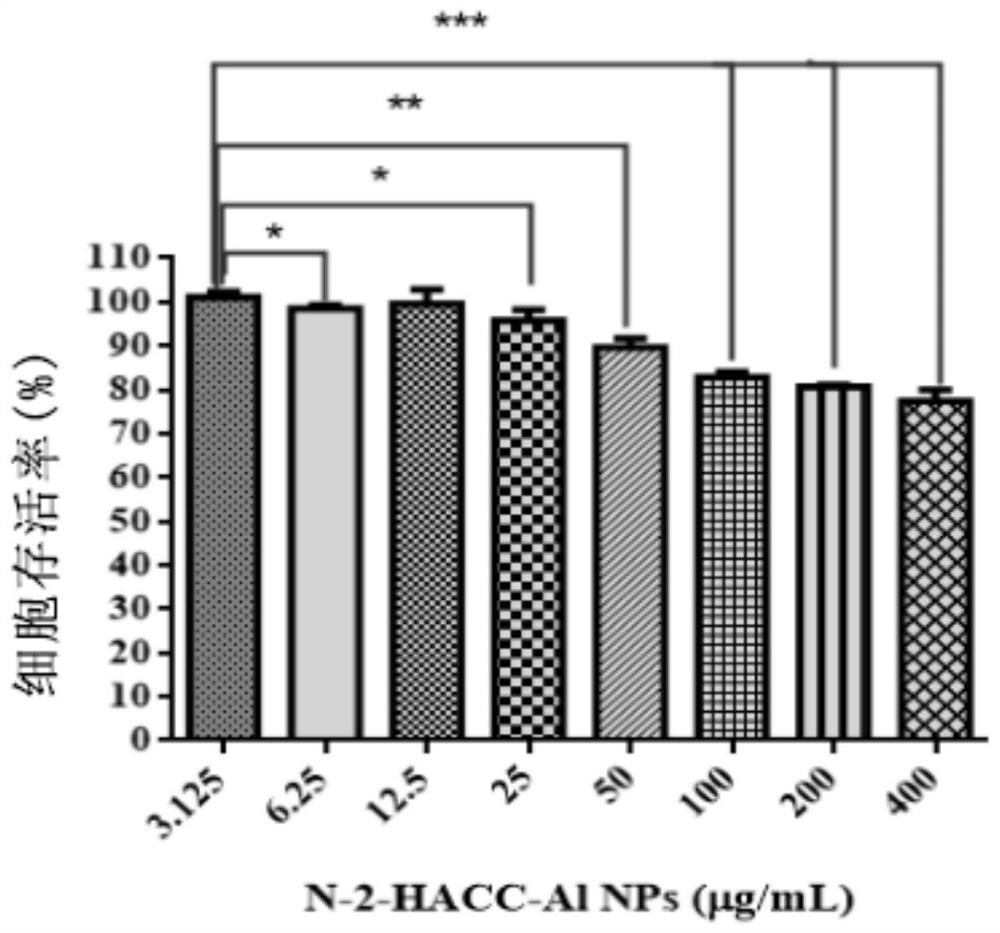

Image

Examples

specific Embodiment approach 1

[0039] Embodiment 1: The preparation method of the composite nanoparticle aluminum adjuvant of this embodiment includes the following steps:

[0040] Step 1: Prepare the soluble aluminum salt solution

[0041] Dissolve the soluble aluminum salt in deionized water, continue stirring at 20°C-50°C for 9 hours, and sterilize at a high temperature of 120°C for 20 minutes; the volume ratio of the mass of the soluble aluminum salt to the deionized water is (0.2~1) g:( 50~200)mL;

[0042] Step 2: Preparation of N-2-hydroxypropyltrimethylammonium chloride chitosan (N-2-HACC) with controllable degree of substitution

[0043]Dissolve chitosan in acetic acid solution, adjust pH to alkaline, filter with suction, wash with deionized water, freeze-dry, then disperse chitosan in isopropanol solution, add 2,3 glycidyl triglyceride dropwise The isopropanol solution of methyl ammonium chloride, after the dropwise addition, stir in a constant temperature oil bath at 70-90°C for 9-10h, then cool...

specific Embodiment approach 2

[0050] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the soluble aluminum salt in step 1 is one or a mixture of any of aluminum chloride, aluminum sulfate, aluminum acetate, and aluminum nitrate. Others are the same as the first embodiment.

specific Embodiment approach 3

[0051] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the volume ratio of acetic acid to deionized water in the acetic acid solution in step 2 is (8-10):(150-300). Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com