Mixing machine for preparing graphite negative electrode material based on needle coke in coating process

A technology of graphite negative electrode and needle coke, applied in mixers, shaking/oscillating/vibrating mixers, mixing methods, etc., can solve problems such as poor affinity, difficulty in embedding asphalt materials, agglomeration, etc., and achieve improved compaction density , enhance the coating effect and shorten the duration of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

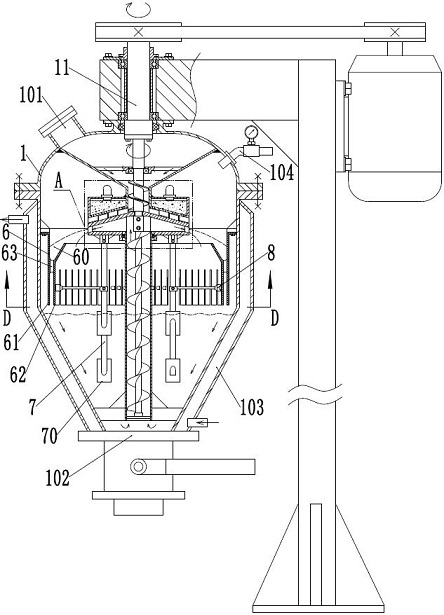

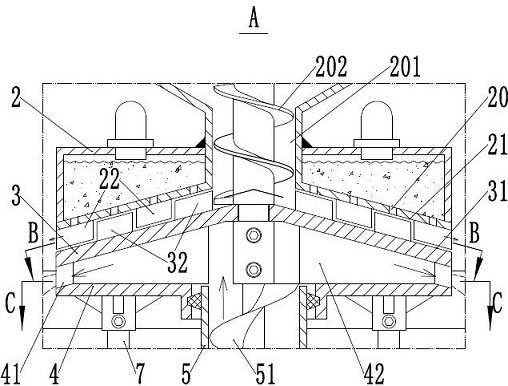

[0032] see Figure 1-Figure 6 , figure 1 It is a schematic diagram of a front view structure of an embodiment of the present invention; figure 2 for the invention figure 1 A schematic diagram of the partially enlarged structure in A; image 3 for the invention figure 2 Schematic diagram of the B-B cross-sectional structure in ; Figure 4 for the invention figure 2 Schematic diagram of the C-C cross-sectional structure in ; Figure 5 for the invention figure 1 Schematic diagram of the D-D cross-sectional structure in ; Image 6 for the invention Figure 5 Schematic diagram of the partially enlarged structure at E in .

[0033] In a specific embodiment, the embodiment of the present invention provides a mixer for preparing a graphite anode material in a coating process based on needle coke, including:

[0034] The tank body 1 has a hollow interior and can be a barrel-shaped structure with an inverted cone-shaped lower end. The tank body 1 has a feeding port 101 above ...

Embodiment 2

[0041] Based on the first embodiment, in order to enhance the effect of forcibly dispersing the materials in the premixing process, in this embodiment, optionally, the upper conical bulk material surface 21 has a plurality of upper bulk material teeth 22 evenly arranged, corresponding to Ground, the lower conical bulk material surface 31 is evenly provided with a number of lower bulk material teeth 32, wherein the upper bulk material teeth 22 and the lower bulk material teeth 32 are arranged in a rotationally dislocated position, such as image 3 As shown, from the inside to the outside in the radial direction, the first and third circles are the lower bulking teeth 32 arranged on the lower conical bulking surface 31 evenly around the axis, and the second and fourth circles are evenly distributed around the axis. The upper bulk material teeth 22 arranged on the upper conical bulk material surface 21, the lower bulk material teeth 32 can also be set with one, three, five, seven....

Embodiment 3

[0044] Based on the first or second embodiment, in order to simplify the excitation mechanism and stably realize the excitation and knock on the shrapnel, in this embodiment, optionally, the vibration excitation mechanism includes: a bracket 7 , a pressing block 8 and a protrusion 9 , the bracket 7 is fixedly connected with the revolving housing 4, and the bracket 7 is provided with the extrusion block 8 near the second elastic piece 62, and the bracket 7 and the extrusion block 8 are arranged in groups and evenly distributed around the axis of the rotating shaft 11 Several groups are provided, and four groups are provided in the figure. The protrusion 9 is provided on the side of the second elastic sheet 62 close to the rotating shaft 11, wherein the extrusion block 8 can elastically abut against the protrusion 9. When the block 8 is detached from the protrusion 9, the second elastic piece 62 vibrates due to the elastic recovery; in order to prevent the extrusion block 8 from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com