Organic base catalyst and method for catalyzing alcoholysis of polycaprolactone by using organic base catalyst

A polycaprolactone and organic base technology, applied in organic compound/hydride/coordination complex catalysts, organic chemistry, chemical instruments and methods, etc., can solve the problem of high temperature, metal residue, long reaction time, etc. problem, achieve the effect of reducing energy loss, saving cost and shortening production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

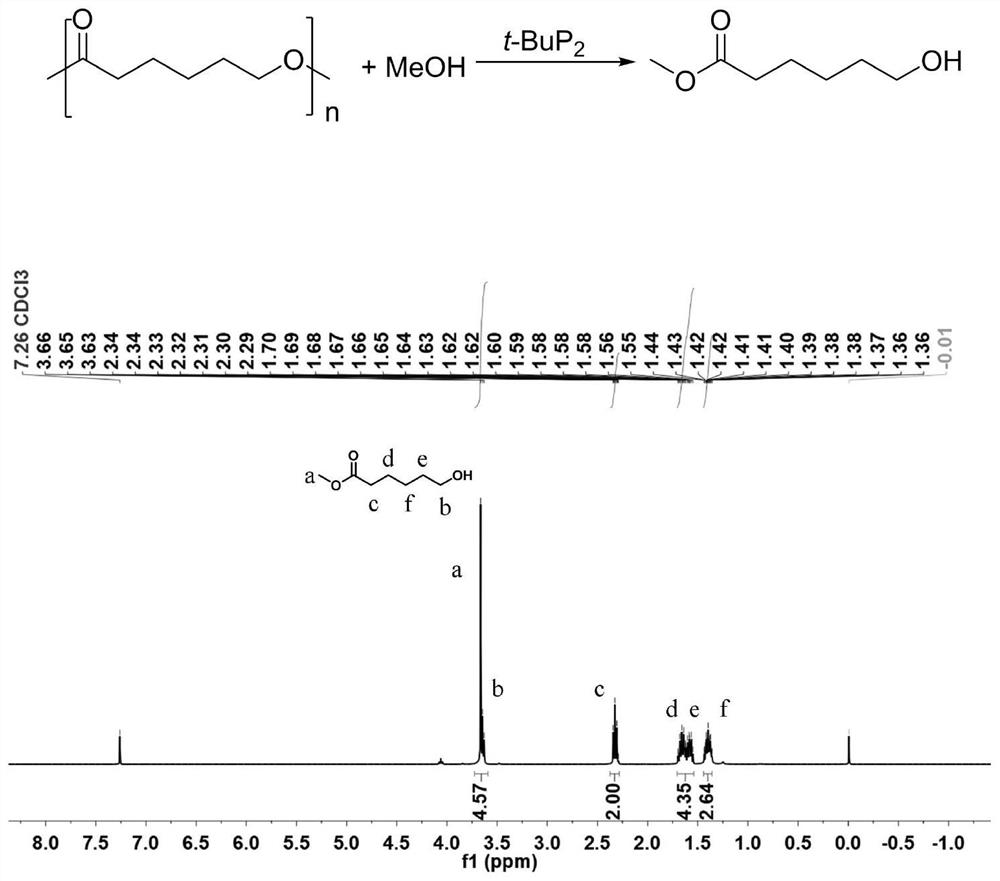

[0028] The reaction process of the present embodiment is as follows:

[0029]

[0030] The specific operation process of this embodiment is as follows:

[0031] Take a 25mL Schlenk bottle, bake it and replace the argon gas, add 1.14g polyε-caprolactone (M n =10.7kg / mol, ), then added 13.9 mg of TBD catalyst, 10 mL of toluene solvent, 5 mL of methanol was added outside the glove box, and the reaction was stirred at 80 °C. After the reaction for 2 h, the reaction system was detected by nuclear magnetic resonance. The conversion rate of the polymer was 92%. - Methyl hydroxycaproate.

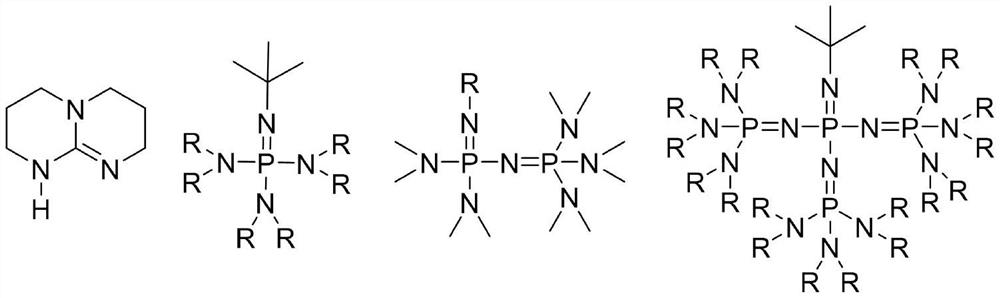

[0032] Among them, TBD is

Embodiment 2

[0034] The reaction process of the present embodiment is as follows:

[0035]

[0036] The specific operation process of this embodiment is as follows:

[0037] Take a 25mL Schlenk bottle, bake it and replace the argon gas, add 1.14g polyε-caprolactone (M n =10.7kg / mol, ), then 13.9 mg of TBD catalyst was added, 5 mL of methanol was added outside the glove box, and the reaction was stirred at 80 °C. After the reaction for 0.5 h, the reaction system was detected by nuclear magnetic resonance. The conversion rate of the polymer was 93%, and the obtained product was 6-hydroxyhexane methyl acid. figure 1 To obtain methyl 6-hydroxyhexanoate 1 H NMR nuclear magnetic spectrum.

Embodiment 3

[0039] The reaction process of the present embodiment is as follows:

[0040]

[0041] The specific operation process of this embodiment is as follows:

[0042] Take a 25mL Schlenk bottle, bake it and replace the argon gas, add 1.14g polyε-caprolactone (M n =10.7kg / mol, ), then 11.75 mg of t-BuP was added 1 Catalyst, 10 mL of toluene solvent, 5 mL of methanol was added outside the glove box, and the reaction was stirred at 80 °C. After 5 hours of reaction, the reaction system was detected by nuclear magnetic resonance. The conversion rate of the polymer was 94%, and the obtained product was methyl 6-hydroxyhexanoate.

[0043] Among them, t-BuP 1 for where R is methyl.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com