High-speed wire rod, large-coil composite wire and production method

A high-speed wire rod and production method technology, which is applied in the direction of manufacturing tools, metal rolling, metal rolling racks, etc., can solve the problems of inability to achieve low-temperature rolling, high investment and operating costs, and inability to achieve collinear production. Achieve the effect of wide range of production specifications, lower heat treatment costs, and high product size accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075]Example 1 - Φ6.0mm small size high-speed wire

[0076] Table 1 The rolling speed and hourly output of each specification of the high-speed wire rod of the present invention

[0077]

[0078]

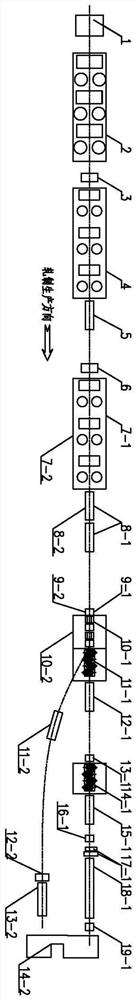

[0079] refer to figure 1 , figure 2 , Image 6 As in Table 1, according to the present invention, the production process sequence includes: heating by heating device, rolling in rough rolling group, flying shearing head and tail after rough rolling, rolling in intermediate rolling group, water cooling and recovery after intermediate rolling, flying shearing after intermediate rolling Cutting head and tail, pre-finishing rolling, water cooling and recovery after pre-finishing, flying shearing head and tail before finishing, three-roll finishing rolling in one group, two-roll finishing rolling in two groups, finishing rolling Post-water cooling and recovery, rolling by reducing and sizing unit, water-cooling and recovery after reducing and sizing, high-speed flying shears s...

Embodiment 2

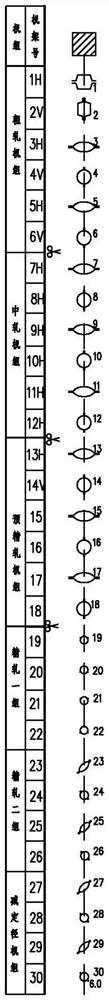

[0092] Example 2 - Φ14.0mm medium-sized high-speed wire rod (without the three-roll finishing mill or the two-roll finishing mill, the finished product is produced by reducing the diameter of the two-roller)

[0093] refer to figure 1 , image 3 , Image 6 As in Table 1, according to the present invention, the production process sequence includes: heating by heating device, rolling in rough rolling group, flying shearing head and tail after rough rolling, rolling in intermediate rolling group, water cooling and recovery after intermediate rolling, flying shearing after intermediate rolling Cutting head and tail, rolling in pre-finishing mill, water cooling and recovery after pre-finishing, water cooling and recovery after finishing rolling, rolling in reducing and sizing unit, water cooling and recovery after reducing and sizing, high-speed flying shear shearing head and tail, wire laying The pinch rollers in front of the machine are used for pinch feeding and spinning, and ...

Embodiment 3

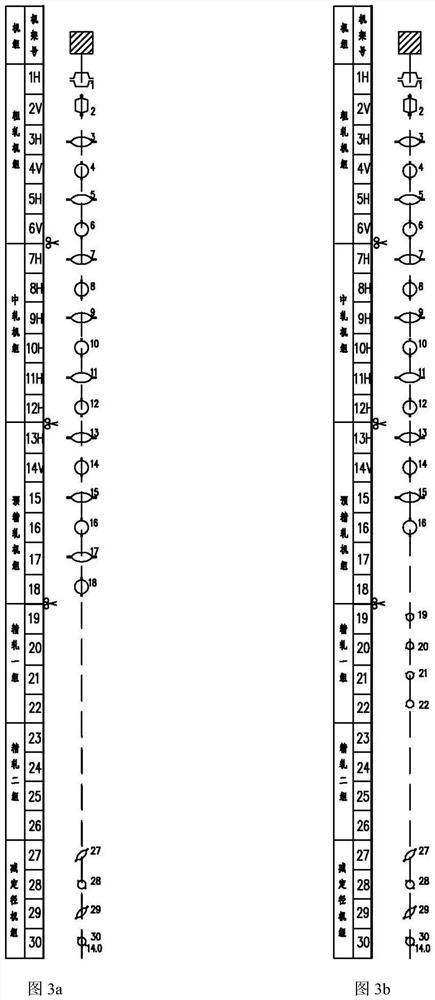

[0104] Example 3 - Φ14.0mm medium-sized high-speed wire rod (through a three-roll finishing mill or a two-roll finishing mill, the finished product is produced by reducing the diameter of the two-roller)

[0105] refer to figure 1 , image 3 , Image 6 As in Table 1, according to the present invention, the production process sequence includes: heating by heating device, rolling in rough rolling group, flying shearing head and tail after rough rolling, rolling in intermediate rolling group, water cooling and recovery after intermediate rolling, flying shearing after intermediate rolling Cutting head and tail, rolling in pre-finishing mill, water cooling and recovery after pre-finishing, water cooling and recovery after finishing rolling, rolling in reducing and sizing unit, water cooling and recovery after reducing and sizing, high-speed flying shear shearing head and tail, wire laying The pinch rollers in front of the machine are used for pinch feeding and spinning, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com