Comprehensive utilization process of red mud and coal gangue under action of short-process mechanical energy

A technology of coal gangue and mechanical energy, applied in the field of materials, can solve the problems of many steps, comprehensive utilization rate less than 20%, insufficient comprehensive utilization rate, etc., and achieve the effect of short process, strong adhesion between particles, and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

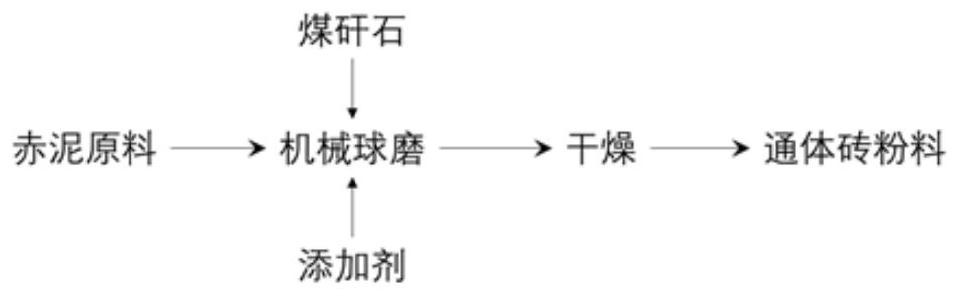

Method used

Image

Examples

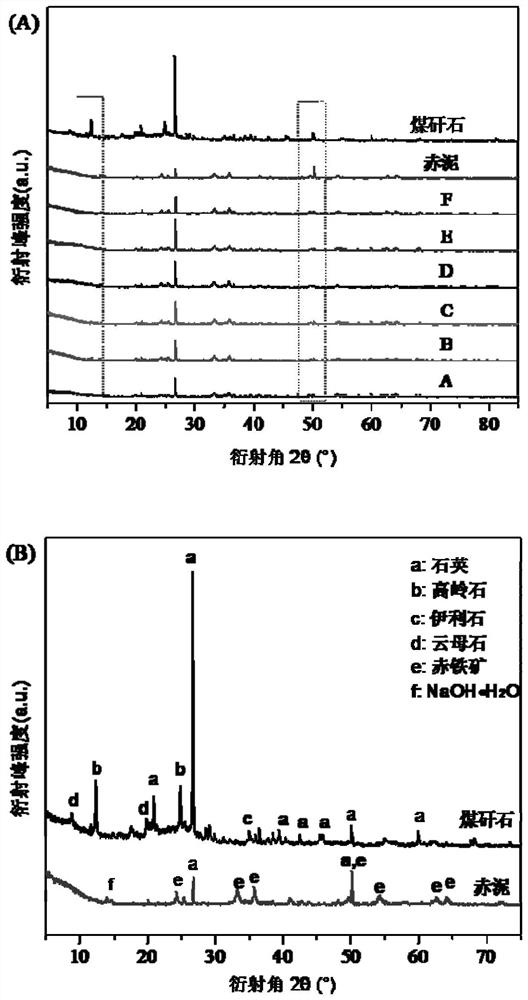

Embodiment 1

[0037] Pour 30kg of red mud, 70kg of coal gangue and 10kg of water glass (30wt.%) additives into a planetary ball mill in turn, perform ball milling at a speed of 100rpm, react under the action of mechanical energy for 1h, and then unload the mixed material, at 70 ℃ The flowing hot air is dried for 12h, and the dry air flow is 1000m 3 / h, that is, to obtain the powder raw materials for the production of full-body bricks, denoted as A.

[0038] In this embodiment, the water in the raw material comes from water glass.

Embodiment 2

[0040] Pour 40kg of red mud, 60kg of coal gangue, and 10kg of water glass (30wt.%) additives into a planetary ball mill successively, carry out ball milling at a rotational speed of 100 rpm, and react under mechanical energy for 30 minutes, and then unload the mixed material. ℃ of flowing hot air for drying treatment for 12h, of which the dry air flow rate is 100m 3 / h, that is, to obtain the powder raw materials for the production of full-body bricks, denoted as B.

[0041] In this embodiment, the water in the raw material comes from water glass.

Embodiment 3

[0043]Pour 40kg of red mud, 60kg of coal gangue, 8kg of water glass (30wt.%), and 2kg of calcium sulfate additive into a planetary ball mill successively, and perform ball milling at a rotational speed of 100rpm, react under the action of mechanical energy for 30 minutes, and then unload the mixture. out, and dry at 70°C with flowing hot air for 12h, wherein the dry air flow is 2000m 3 / h, that is, to obtain the powder raw material for the production of full-body bricks, denoted as C.

[0044] In this embodiment, the water in the raw material comes from water glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com